9

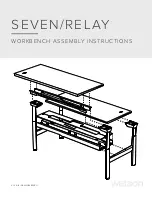

6 pole DIN socket

Manual controls

8 pole DIN socket

Table column 2

8 pole DIN socket

Table column 2

8 pole DIN socket

Table column 1

8 pole DIN socket

Table column 1

6 pole DIN socket

Manual controls

Table E: ST2

8 pole DIN socket

Table column 4

8 pole DIN socket

Table column 3

Table 4 E: ST4

Control units

The synchronous control systems are used to control height-adjustable table

systems for 2 or 4 table columns

2 table columns EU; 230 VAC

USA/CDN; 120-277 VAC

4 table columns EU; 230 VAC

USA/CDN; 120-277 VAC

The on-time is 10%, which means that the table columns can

be run for 2 minutes in continuous operation and will then

switch off for 18 minutes.

Check the seating of all plug connections.

Use a power cord to connect to the mains.

The control system and manual controls must be positioned and secured as

appropriate to local conditions. If necessary, alter their position.

The installation site should be dry, free of dust and away from direct sunlight.

The environmental temperature for operating the control system must not fall

below 5 °C or above 35 °C.

Consequently, you should not install the control system:

- above or in front of heat sources (e.g. radiators),

- in locations that are exposed to direct sunlight,

- in small, unventilated, damp rooms,

- on or near highly flammable materials or

- near high-frequency devices

(e.g. transmitters, radiation-emitting devices or similar equipment).

Ensure that connecting cables and electrical lines are not bent, pulled or

subjected to mechanical loads. In particular, cables must not be clamped in

the foot area of the table columns (safety area of approx. 10 mm around the

table column feet).

It is advisable to install surge protection to protect against the types of

electrical surges that can occur during thunderstorms. Consult an electrical

engineer.

Never open the control system’s housing or the power pack! Unauthorised

opening of the housing and inappropriate repairs can cause hazards for us-

ers and shall invalidate the warranty. Only the manufacturer’s personnel are

authorised to open or repair the electrical systems.

Do not allow any liquids to penetrate inside the control system or the power

pack as this could result in an electric shock or short circuit.

Use only a dry or slightly damp cloth to clean the control system and the

manual controls.

Stop using the device immediately if it begins to emit smoke or odour, makes

unusual noises or shows visible signs of damage. Disconnect the system

from the mains by removing the plug.

The control system may only be used with item table columns.

5. Electrical connections for height-adjustable tables

Observe the following points when installing and operating the control system: