6

If a slide is located on two parallel guide rails, initially the faste-

ning screws of both rails should only be lightly tightened.

The carriage plate is then aligned with all the guide carriages

and screwed to them (M

A

= 5.8 Nm, refer to section ’Setting up

the Guide Carriage’). In order to ensure parallel alignment, this

slide must then be moved a number of times along the rails. To

protect the wipers during this operation, lengths of adhesive

tape must be applied to the upper surfaces of the rails in order

to cover the sharp edges of the holes. Only when both rails

have been aligned in parallel and at the correct angle should

the guide rails be screwed down by applying the tightening

torque specified above, working from the centre of the rail to

both ends; all the holes are then sealed with the plastic plugs.

Installing the Guide Rail

As a result of the internal stresses generated when the guide rails are ground

to shape, a rail in as-supplied condition may not be perfectly straight. However,

this condition will be rectified when the rail is screwed onto the profile groove.

For this reason, it may be advisable to obtain approximate alignment to the

profile groove with a number of screws before the final tightening operation.

The 1,900 mm long guide rails are factory-prepared at both ends to accept the

guide carriage.

If a rail is shortened, it is important to ensure that after it is fastened

down, the carriage can be slid onto the rail at the non-shortened end.

If the guide is installed flush in an enclosing structure, the carriage must be

placed onto the guide rail prior to assembly.

Cut Groove Profile 8 Al to the right length for the guide rail and insert it into

the guide groove provided. The rail is 20 mm longer than Groove Profile 8 Al in

order to allow space for any connecting elements of the connecting structure.

Place the guide rail onto the groove and remove the protective film from the top

of the rail.

Insert the screws, DIN 912 M4x16 Property Class 10.9 (No. 0.0.406.75) into

the holes in the guide rail and tighten them by hand. Avoid tilting the guide rail

and ensure that it is aligned in terms of position and angle.

The recommended maximum tightening torque for these fastening

screws is 4.8 Nm. Build up to this figure by tightening alternate screws

in three stages:

Pass 1: to 2.0 Nm

Pass 2: to 3.5 Nm

Pass 3: to 4.8 Nm

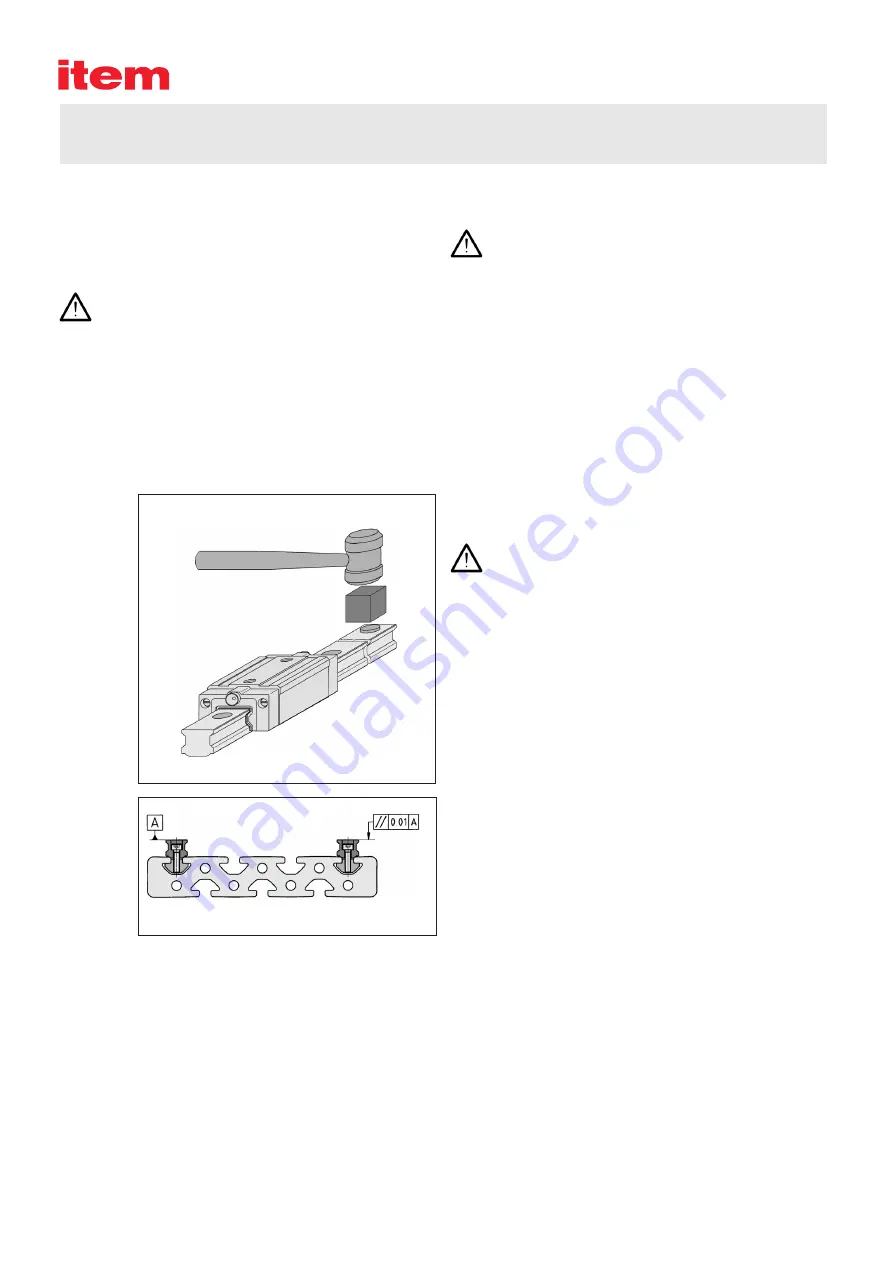

Once the rail has been screwed down, insert the plastic plugs

into the holes and secure them with the aid of a block. Remove

the abraded plastic edge and deburr the hole with an oilstone.

It is not possible to remove the plastic plugs without

irreparably damaging them. If you decide to remove

the guide rail at a later date, the plastic plugs (No.

0.0.443.08) must be replaced before the Linear Guide

System is returned to service. If this is not done, the wi-

pers of the guide carriage will be damaged by running

over the sharp edges of the holes.