-7-

(

2

)

Second stage: 10-inch granular activated carbon filter

Can effectively adsorb free chlorine, humus, disinfection byproducts, smells, discoloration, and other

substances in water.

(

3

)

Third stage: 10-inch CTO filter

Can further remove particles of a smaller size, such as suspended solids and colloids.

(

4

)

Fourth stage: side stream reverse osmosis membrane

Pore size of 0.0001 microns (0.1nm), reduces bacteria by 4,000 times, reduces infectious viruses by

more than 200 times, therefore it can effectively remove bacteria, viruses, heavy metals, pesticide

residues, and other harmful substances.

(

5

)

Fifth stage: granular activated carbon post-filter

Removes odor and adjusts taste.

Note: Due to technical improvements, the above 5 stage filters may change, please take practicality as

standard.

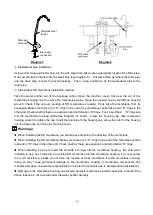

6. Function Introduction of Accessory

(1 )

High Pressure Pump

:

Boosts pressure to create a stable working environment for the RO membrane.

( 2 ) Low Pressure Switch

:

To prevent pump idling. When the inlet water pressure is less than 0.03MPa or

when the inlet water stops, the low-voltage switch automatically shuts off the power

source so the machine stops.

( 3 ) High Pressure Switch: To prevent pump rotating full. It automatically shuts off the power source so the

machine stops when pressure of pure water attains rated one.

( 4 ) Inlet Water Solenoid Valve: Connects or cuts off incoming water. Operating pressure range is less than

≤0.6MPa.

( 5 ) No Return Valve: Also known as a one-way valve, control the flow direction.

( 6 ) Manual Flush Valve: Manual flushes the reverse osmosis membrane.

( 7 )Electric Adaptor: Converts 110-220V AC to 36V DC

(the machine’s safe operating voltage).

7. Specifications

(1)

Without tank:

Completely advanced design, big flow volume, directly drink when open machine, safe

and healthy.

(2)

Big flow volume:

About 1.3L per minute

(

25

℃)

.

(3)

Low-pressure start:

Low water pressure starts, only requires 0.03MPa.

(4)

MLSB membrane element production technology:

Makes the membrane utilization rate reach world

leading levels, increases water production volume, reduces wastewater emissions.

(5)

Anti-Pollution Low Pressure RO Membrane

: Without storage water tank, ration between pure water

and waste water is up to 1:1, save water and power; Waste water volume is only 60% of traditional

machine.

(6

)

New Generation big flow booster pump:

Low noise, high efficiency, the flow and pressure are 20%

more than 300GPD booster pump.

(7

)

Flush Function:

The system flush function can be manual controlled. The water flush process is for

the RO membrane to ensure more reliable and safe operation of this machine.