14140 NE 200th St. Woodinville, WA. 98072 PH: (425) 398-8282 FX: (425) 398-8383

FlexJet Carriage upgrade

Tools Required:

Philips screwdriver

9/64 (3.5mm) Allen wrench

5/16 (8mm) open end wrench

Small flat tipped screwdriver

Notices:

Warning!

Ensure that all AC power cables are removed from the printer before attempting these procedures.

Attention!

The discharge of static electricity may damage the carriage and logic board components. Use the included

ground strap during all procedures. Keep plastic objects away from the carriage and logic board assemblies.

Warning!

The FlexJet is heavy and could cause serious injury or death if it falls or rolls over. Make sure that a minimum of

two people move it, especially when detached from the stand.

Prepare the printer

a) Turn the FlexJet power off.

b) Clear paper from around the carriage.

c) Remove inkjet cartridges. Do NOT cover the

cartridge heads with anything.

d) Remove the AC power cable and any other

cables connected to the rear of the printer.

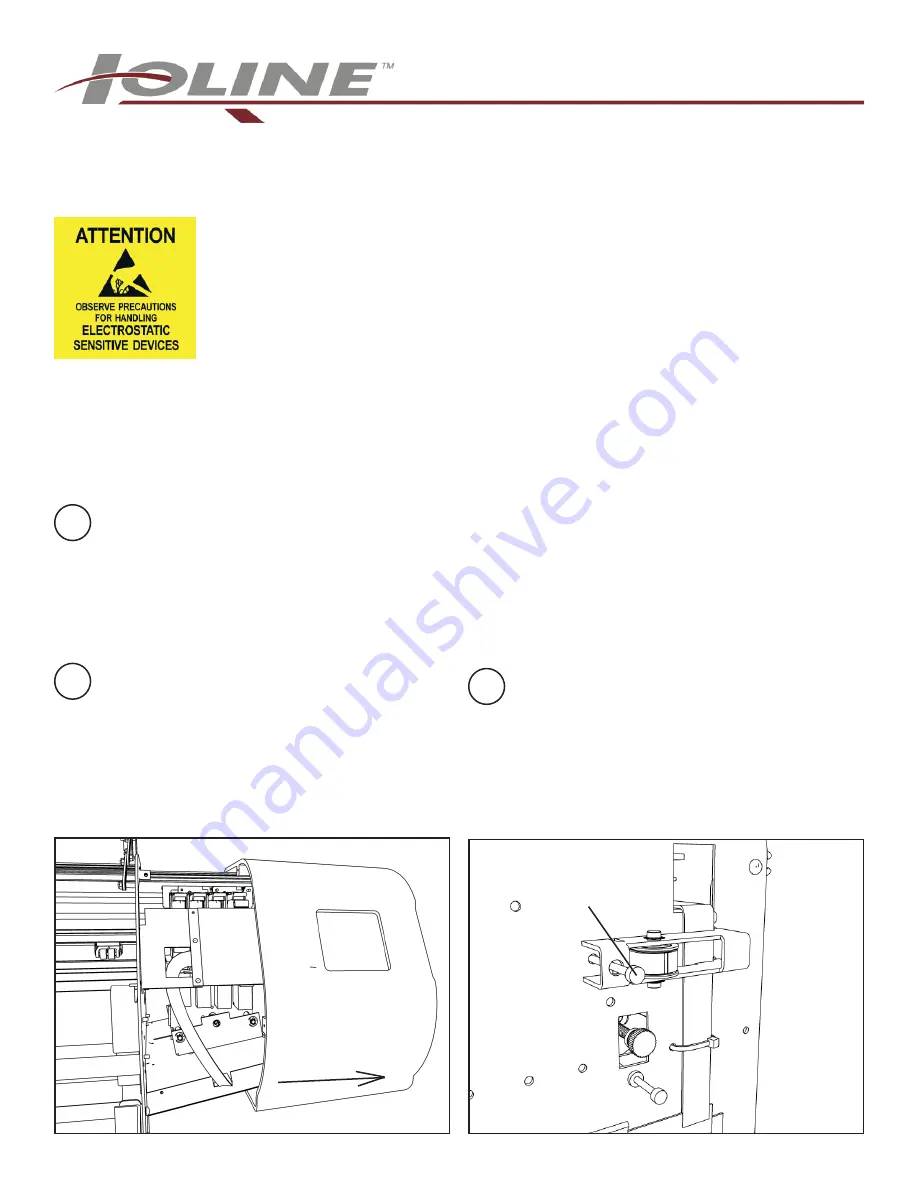

Remove the end cover

a) Unplug the roll feed motor under the right end

cover.

b) Remove the 5 screws that hold the plastic end

cover on to the right end of the printer. There

are two on the flat surface of the endplate,

one screw in the back, and 2 screws on the

bottom.

Loosen the Carriage Belt

a) Find the belt tensioner on the right side above

the white cables.

b) Loosen the carriage belt tensioner by rotating

the 9/64” HEX screw 4 full counterclockwise

turns.

1

2

3

Included with the upgrade kit

1) Screws for mounting the new board (3)

2) New daughter board

3) Standoffs (2 short, 1 long)

4) Flex cables (1 short, 4 long)

5) Carriage assembly with flex cables

6) Belt tensioner assembly

7) Tyraps (8)

8) Double stick foam tape

9) Grounding wrist strap

10) This procedure

Remove Cover

Loosen this screw

(9/64”)

P/N: 108384 R0