21

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Thermopile

TH

TP

TH

TP

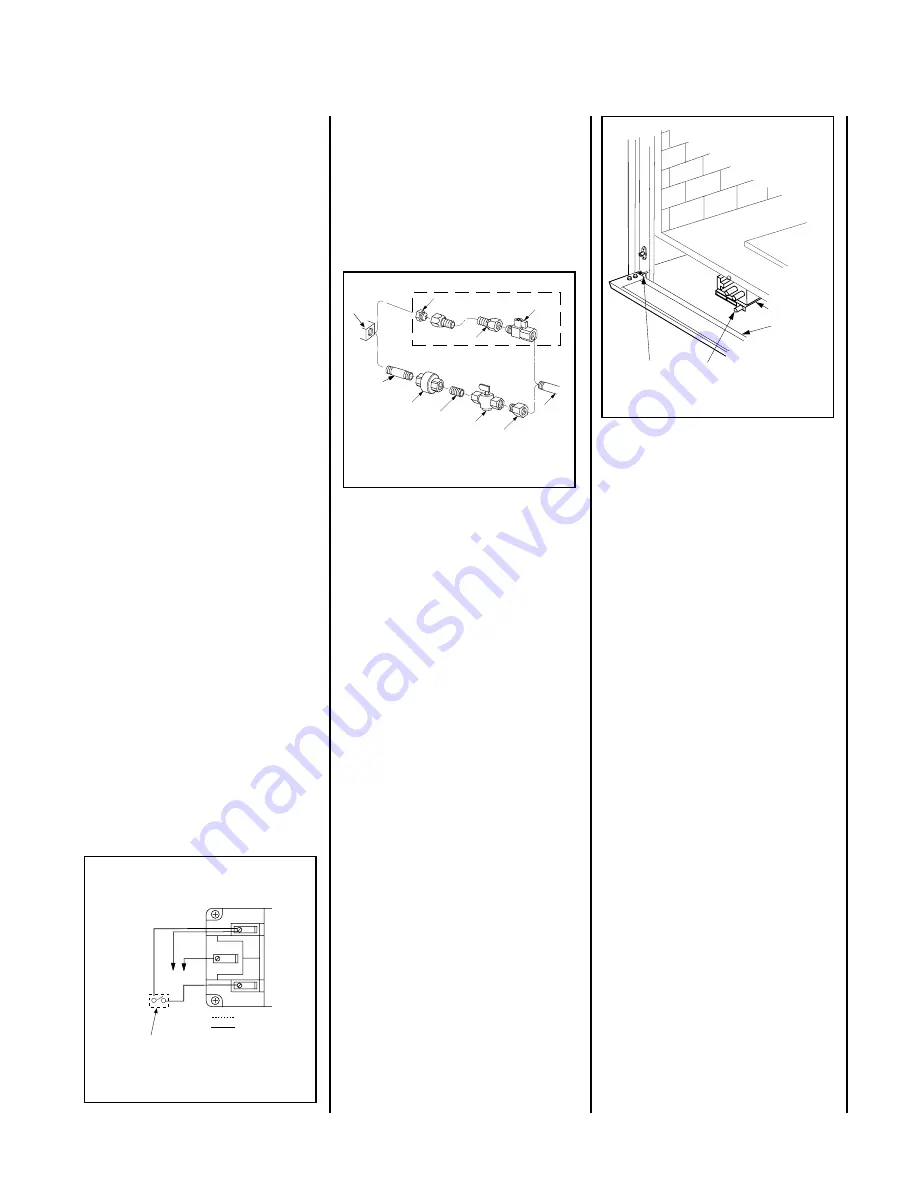

Millivolt Wiring Diagram

If any of the original wire as supplied must be replaced, it

must be replaced with

Type AWM 105°C 18 GA. wire.

*OPTIONAL APPLIANCE-MOUNTED ON/OFF SWITCH,

OPTIONAL WALL-MOUNTED ON/OFF SWITCH,

OPTIONAL THERMOSTAT

OR OPTIONAL REMOTE CONTROL RECEIVER

Factory Wired

Field Wired

Schematic Representation Only

Figure 47

Note:

Secure Flex

vent must be attached to

Secure Flex

terminations only. DO NOT sub-

stitute

Secure Vent

terminations or the

Se-

cure Vent

adapter for

Secure Flex

compo-

nents. The collars of

Secure Flex

termina-

tions and adapters have a different diameter

than that used with the

Secure Vent

pipe.

Additionally,

Secure Flex

components have

an extended length center tube for use in

attaching the flexible vent.

Step 4. MILLIVOLT CIRCUIT WIRING

(

Figure 47

)

The gas valve is set in place and pre-wired at

the factory.

1

. Select any of the following optional

controls: appliance-mounted (rocker

switch) or wall-mounted switch, ther-

mostat, or one of the optional remote

control kits. If appliance-mounted ON/

OFF control is selected, mount it in the

gas valve mounting bracket.

2

. If wall-mounted ON/OFF control or ther-

mostat is selected mount it in a conve-

nient location on a wall near the fireplace.

3

. Wire the control within the millivolt con-

trol circuit using the 15 feet of 2 conduc-

tor wire supplied with the unit.

Caution: Do not connect the optional

wall switch to a 120V power supply.

4.

Alternatively, the appliance may be oper-

ated without the use of the controls indi-

cated in step 1, solely by manipulating

the gas valve control knob. In order to

use this method, twist the free ends of

the two conductor wire (located on top of

the unit) together as shown in

Figure 47

.

Note: The supplied 15 feet of 2 conductor

wire has one end of each conductor

connected to the gas valve circuit and the

other end of each conductor placed

loose on top of the unit.

Gas Stub

¹₂

" x

³₈

" Flare

Shut-Off Valve

³₈

" Flex Tubing

³₈

" NPT x

³₈

"

Flare Fitting

³₈

" Nipple

³₈

"

Union

³₈

" Close Nipple

³₈

" Shut-Off Valve

¹₂

" x

³₈

" Reducer

Gas

Valve

Gas Flex Line Connector

Figure 49

Figure 48-

GAS CONNECTION

Turn on gas supply and test for gas leaks using

a soapy water solution.

Never use an open

flame to check for leaks

.

A.

Mix a 50% dish soap, 50% water solution.

B.

Light the appliance (refer to the lighting

instructions provided in the Homeowner's Care

and Operation Instructions).

C.

Brush all joints and connections with the

soapy water solution to check for leaks. If bubbles

are formed, or gas odor is detected, turn the gas

control knob to the “OFF” position. Either tighten

or refasten the leaking connection and retest as

described above.

D.

When the gas lines are tested and leak

free, observe the individual tongues of flame

on the burner. Make sure all ports are open

and producing flame evenly across the

burner. If any ports are blocked, or partially

blocked, clean out the ports.

Step 5

.

CONNECTING GAS LINE

Make gas line connections. All codes require a

shut-off valve mounted in the supply line.

Figure 48

illustrates two methods for con-

necting the gas supply. The flex-line method is

acceptable in the U.S., however, Canadian

requirements vary depending on locality. In-

stallation must be in compliance with local

codes.

These appliances are equipped with a gas flex

line for use (where permitted) in connecting

the unit to the gas line. A gas flex line is

provided to aid in attaching the direct vent

appliance to the gas supply. The gas flex line

can only be used where local codes permit.

See

Figure 48

for flex line description. The

flex line is rated for both natural and propane

gas. A manual shut off valve is also provided

with the flex line.

The gas control valve is located in the lower

control compartment. To access the valve

proceed as follows:

Secure all joints tightly using appropriate

tools and sealing compounds (ensure pro-

pane resistant compounds are used in pro-

pane applications).

The millivolt control valve has a

³⁄₈

"

(10 mm) NPT thread inlet port.

Open the control compartment access panel,

(Figure 49)

by actuating the spring-loaded

magnetic catches securing the panel, gently

depressing the outer top corners of the panel

until the catches "pop" the panel free and

allowing it to swing out and down to open.

Piezo Ignitor

Gas Valve

Control

Compartment

Access panel

Hinge Pin

f i r e - p a r t s . c o m