9

ATTACH THE REMOTE CONTROLLER MOUNTING

BRACKET

1. Use the two screws supplied with the controller to attach

the mounting bracket to the wall in the location selected

by the customer (see Fig. 10).

2. Install batteries in the remote control.

3. Place remote control into remote control mounting brack-

et.

4. For remote control operation, refer to the unit Owner’s

Manual.

REMOTE CONTROL

REMOTE CONTROL

MOUNTING BRACKET

Fig. 10

—

Attach Mounting Bracket to the Wall

(OPTIONAL)

NADA001TW

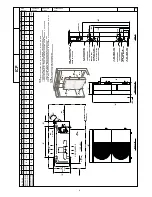

Fig. 11

—

Wall Mounted Unit – RTX

Outdoor Unit Installation

NOTE

: The outdoor unit must be installed on a solid surface

(mounting base).

1. Place the rubber absorption cushions (supplied with the

outdoor unit) under the unit’s feet to prevent vibrations.

2. Fasten the outdoor unit legs to the mounting base, as

shown in Fig. 12. The cushion goes between the legs and

the mounting base.

3. Be sure that the unit is leveled.

MAKE REFRIGERANT PIPING CONNECTIONS (OUT-

DOOR UNIT) — To connect the refrigerant lines:

Make sure to properly identify and separate between the piping

and control cables coming from indoor unit No. 1 and the piping

and cables coming from indoor unit No. 2

Use only ”L” type sealed, dehydrated copper refrigerant tubing.

No other type of tubing may be used. Use of other types of tubing

will void the manufacturer’s warranty.

Do not open service valves or remove protective caps from

tubing ends until all the connections are made.

Bend tubing with special bending tools to avoid the formation of

sharp bends. Take care to avoid kinks or flattening of the tubing.

Keep the tubing free of dirt, sand, moisture, and other

contaminants to avoid damaging the refrigerant system.

Avoid sags in the suction line to prevent the formation of oil

traps.

Insulate each tube with 3/8

−

in. walled thermal pipe

insulation. Inserting the tubing into the insulation before

making the connections will save time and improve

installation The suction and mixed

−

phase lines should never

come in direct contact.

4 ABSORPTION CUSHION TO

BE PUT UNDER EACH LEG

INTER UNIT

TERMINAL BLOCK

N L1

115 VAC

1

2

3

4

5

24 V

AC

FAN (H)

FAN (L)

R.V.S

COMP.

COMMON

1

2

3

4

5

24 V

AC

FAN (H)

FAN (L)

R.V.S

COMP.

COMMON

1

2

METAL CONDUIT

CONNECTION PLATE

1

2

3

4

5

24 V

AC

FAN (H)

FAN (L)

R.V.S

COMP.

COMMON

TH3 SENSOR

(HEAT PUMP ONLY)

POWER SUPPLY

CABLE

INTER UNIT CABLE

N L1

115 VAC

1

2

3

4

5

24 V

AC

FAN (H)

FAN (L)

R.V.S

COMP.

COMMON

1

2

3

4

5

24 V

AC

FAN (H)

FAN (L)

R.V.S

COMP.

COMMON

1

2

HIGH/LOW

VOLTAGE METAL

BARRIER

POWER SUPPLY

TERMINAL BLOCK

Fig. 12

—

Legs Mounting Base and Wiring Outdoor

Units

Models: DFC2A/H318J2A, DFC2A/H324J2A