10

OFF ON

TIMER

IR RECEIVER

FILTER

PLASTIC CONTROL

COVER

SERVICE LED

Operation push button for

automatic operation (23

°

C/73

°

F),

turning the a/c OFF, canceling

the malfunction indication,

and resetting the filter LED.

INDOOR UNIT

2 X 09, 2 X 12

Fig. 12A — Indoor unit LED’s and Wiring

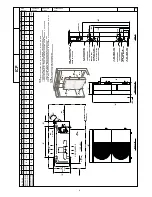

FLARING AND CONNECTING REFRIGERANT LINES

1. Remove the protective cap from the flare fitting.

2. Remove the protective cap from the tubing and cut to the

required length. Be sure that the cut is perpendicular and

clean, without burrs.

3. Slip the flare nut on the tubing and flare the tube end using

standard flaring tools.

4. Tighten the nut until resistance is met. Mark the nut and

the fitting. Using a suitable wrench tighten an additional

¼

turn. Use the following specified torque, according to con-

nection size:

Mixed

−

Phase line:

Suction line:

1/4 in.

−

(12.3 ft

−

lb.) 1/2 in.

−

(36 ft

−

lb.)

Both refrigerant lines need to be insu-

lated separately

NOTE

: The service valves on the outdoor unit must remain

closed until all 4 connections have been made.

EVACUATE TUBING AND CHARGE THE SYSTEM —

When all the fittings are connected, air must be expelled, then

refrigerant charge must be checked and adjusted. Follow the steps

below.

1. Open the service port cap on the suction line valve (large

valve of unit No. 1).

2. Connect the vacuum pump to the service port of unit No.

1 via the pressure gage and evacuate to 500 microns to

eliminate contamination and moisture.

3. Disconnect the vacuum pump. Unit should maintain 500

microns for 5 minutes.

4. Remove the service port caps from the mixed

−

phase valve

and suction line valve

5. Open the mixed

−

phase valve (small valve) with an Allen

wrench.

6. Open the suction line valve (large valve) with an Allen

wrench.

7. To evacuate and charge unit No. 2 repeat steps 1 thru 6.

8.

The outdoor unit is supplied with sufficient R

−

22 re-

frigerant for up to 25 ft. lineset length. Add 0.9 oz. of

refrigerant for each additional 3 ft. of tubing length.

9. Make sure that the valves are properly opened. Be careful

not to open them more than required as this may damage

the thread.

10. Replace the service port cap. Using refrigerant oil, lubri-

cate the cap beam and hand tighten until resistance is met.

Use a suitable wrench to tighten the cap by an additional

1/2 turn.

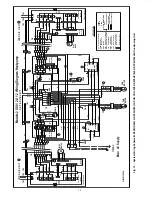

Power Supply

— See Tables 4 and 5 for electrical data and Fig.

13

−

14 for system wiring diagrams.

Leak Test

— Leak test all fittings with appropriate test

equipment.