Chapter 5 — Firmware Download

ED40 Decode Board Integration Guide

41

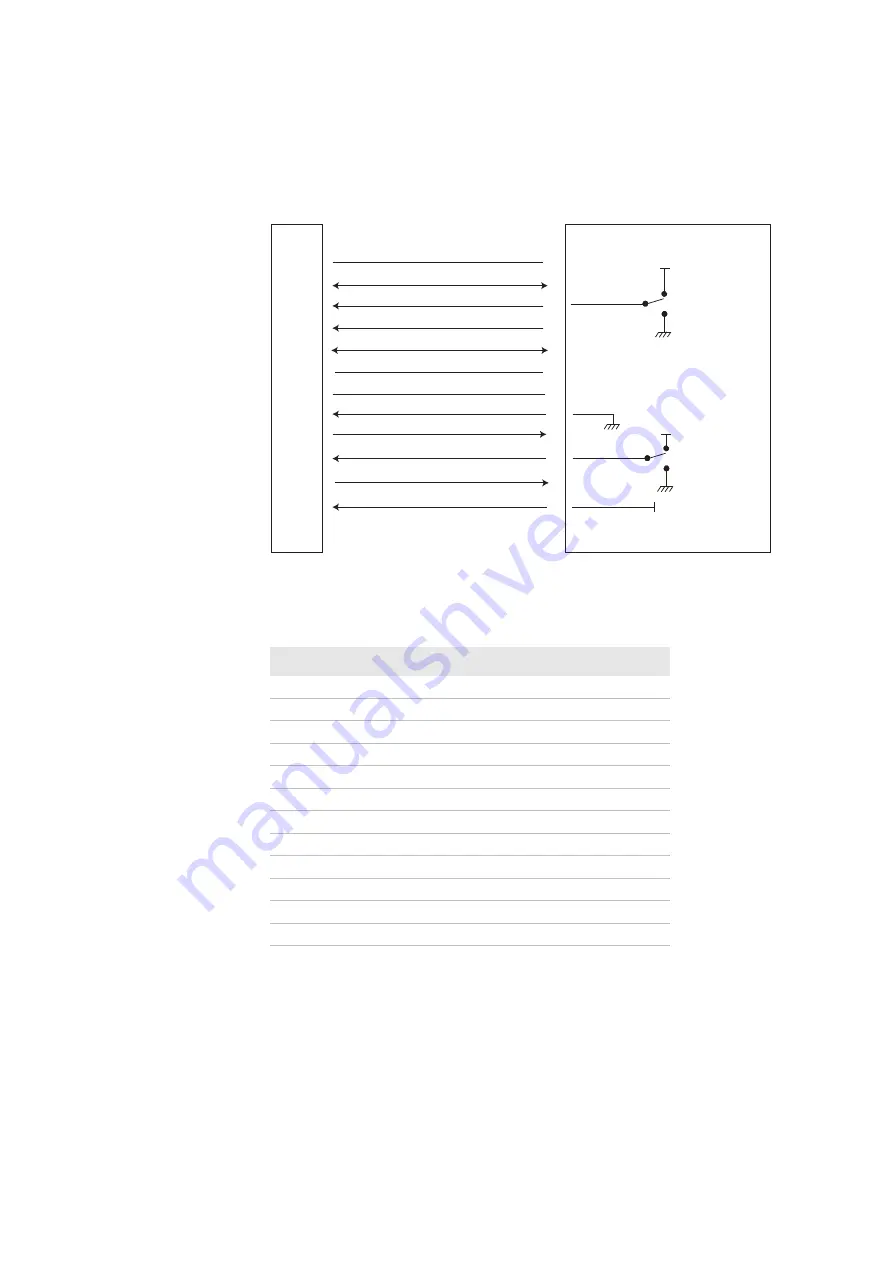

USB Interface

When performing a firmware download using the USB interface, the decode

board automatically uses a USB Virtual COM interface. For first time use of the

USB Virtual COM interface, see

Connections for Firmware Download—USB Interface

Contact Description—USB Interface Firmware Download

Host Contact

Description

1

Vcc Scanner

2

USB D+

3

Must be connected to Vcc

4

Power Enable

5

USB D-

6

Do not connect

7

GND Scanner

8

Must be connected to GND

9

LED

10

Must be connected to Vcc

11

Buzzer

12

Must Be Connected To Vcc.

ED40

HOST

1

2

3

4

5

6

7

8

9

10

11

12

USB D+

Trigger

Power enable

USB D-

Do not connect

GND

Detect in 1

LED

Detect in 2

Buzzer

Detect in 0

Vcc

trigger on

Vcc

trigger off/

firmware download

Vcc

Vcc

normal operation

firmware download

Summary of Contents for ED40

Page 4: ...iv ED40 Decode Board Integration Guide ...

Page 22: ...Chapter 2 Mechanical Integration 10 ED40 Decode Board Integration Guide ...

Page 32: ...Chapter 3 Electrical Integration 20 ED40 Decode Board Integration Guide ...

Page 48: ...Chapter 4 ED40 Setup 36 ED40 Decode Board Integration Guide UPC A ...

Page 50: ...Chapter 4 ED40 Setup 38 ED40 Decode Board Integration Guide ...

Page 92: ...Appendix A EA11 Imager 80 ED40 Decode Board Integration Guide ...

Page 130: ...Appendix C EA21 Imager 118 ED40 Decode Board Integration Guide ...

Page 153: ...Appendix D EA30 Imager ED40 Decode Board Integration Guide 141 ...

Page 154: ......