SRPL8 Server System 11

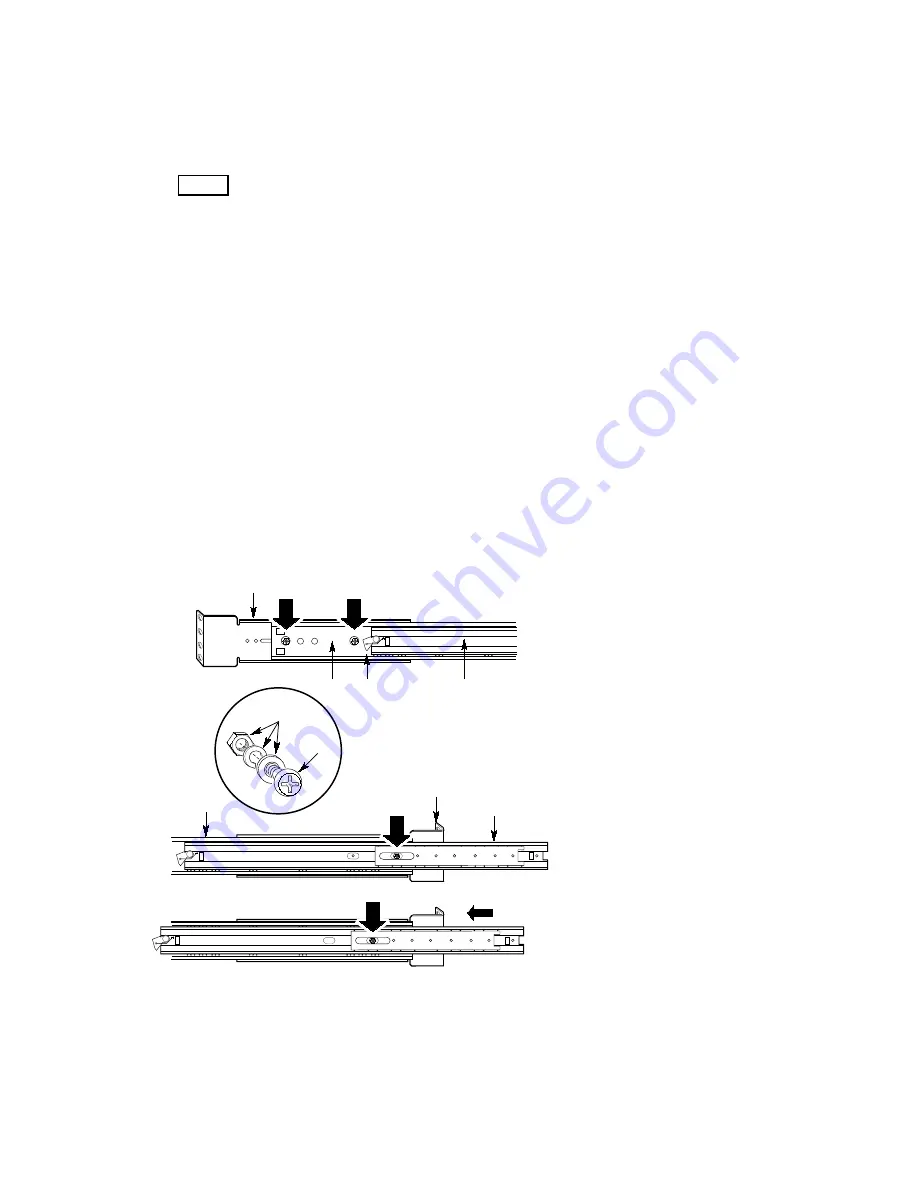

Attach the Center Bar and Large Outer Bar Assemblies to the

Equipment Rack

1. Orient a center bar and large outer bar assembly so that the flat side is facing toward the

brackets attached to the vertical rails and the safety latch on the center bar is near the back of

the rack.

2. Press the flat side of the outer bar into the U-shaped sections of the brackets.

3. Slide the assembly toward the front of the rack until the end of the outer bar is flush with the

end of the U-shaped section of the front bracket.

4. Gently slide the center bar toward the front of the rack, and position the oblong slot in it over

the first hole in the large outer bar. Insert a screw through the hole in the bar and the first hole

in the front bracket. Place a lock washer and a nut on the screw, and loosely tighten it.

5. Position the oblong slot in the center bar over the third hole back from the front of the large

outer bar. Insert an 8-32 screw through the hole and the oblong slot in the front bracket. Place

a lock washer and an 8-32 nut on the screw, and loosely tighten it.

6. The back bracket has two holes and three slots in it. This end of the outer bar has four holes in

it. Which holes and slots you use depend on the depth of the equipment rack. After fitting the

bar into the bracket, insert two screws through the holes in the bar and the appropriate oblong

slots in the bracket. Place a lock washer and a nut on each screw, and loosely tighten them.

7. Ensure that the brackets and bars are positioned correctly in the rack. Then tighten all screws

firmly (6.0 inch-pounds).

OM11072

A

B

C

B

B

E

F

D

D

F

G

B

B

A. Back right-angle extension bracket

B. Screw

C. Flat washer, lock washer, and nut

D. Large outer bar

E. Safety latch on the center bar

F. Center

bar

G. Front right-angle extension bracket

Figure 7. Center Bar and Large Outer Bar Assembly

Summary of Contents for SRPL8

Page 33: ......

Page 34: ...34 Quick Start Guide...