TNi21

07 April 2016

Page

24/38

7. TECHNICAL CHARACTERISTICS

7.1. Electrical data

Maximum product characteristics

Parameters

Value

Unit

Supply voltage V

DC_MAX

56

(*)

V

Maximum current I

DC_MAX

20

A

Maximum voltage at the inputs V

IN_MAX

50

(*)

V

Maximum voltage at the outputs V

OUT_MAX

56

(*)

V

Maximum current at the outputs I

OUT_MAX

50

mA

Operating characteristics

Parameters

Min.

Typical

Max.

Unit

Power supply voltage V

DC

10

12 / 24 / 32

36

V

Peak current I

DC

-

-

17

A

Motor consumption at rest without holding I

0

-

75

-

mA

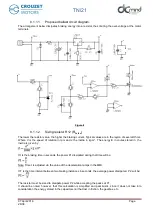

Input characteristics

Parameters

Min.

Typical

Max.

Unit

Input impedance between E1 and E2 R

IN_TOR

-

57

-

kΩ

Input impedance between E3 and E4 R

IN_ANA/PWM

-

69

-

kΩ

Low logic level on inputs E1 to E2 V

IL_TOR

0

-

2

V

High logic level on inputs E1 to E2 V

IH_TOR

4

-

50

(*)

V

Low logic level on inputs E3 to E4 V

IL_PWM

0

-

2

V

High logic level on inputs E3 to E4 V

IH_PWM

7.5

-

50

(*)

V

Frequency of PWMs on input

100

-

2000

Hz

Resolution of proportional inputs

10

bits

Output characteristics

Parameters

Min.

Typical

Max.

Unit

Low logic level on outputs S1 to S3 V

OL

R

L

= 4K7Ω, V

DC

= 24V

0

-

0.2

V

High logic level on outputs S1 to S3 V

OL

R

L

= 4K7Ω, V

CC

= 24V

V DC

–

0.5V

-

V DC

V

Type PNP open slip-ring

(*)

36V prior to 15 October 2015

7.2. Generic data

General characteristics

Parameters

Value

Unit

Motor ambient temperature

-30 to +70

°C

Insulation class (complies with directive IEC 60085)

E

/

Protection index (other than shaft axis)

IP65M

/