危

险

!

CAUTION

Vacuum

pumping

-Do use Nitrogen.

Air tight procedure

Completion

of

Ref

.

Piping

Repairing

of

Leakage

Part

Check

of

Pressure

Decrease

Applying

Nitrogen

Gas

Pass

Procedure

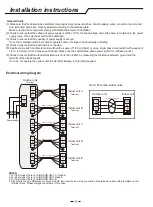

Connect the gauge manifold using charging hoses with a nitrogen

cylinder to the check joints of the liquid line and the gas line stop valves

.

Perform the air

-

tight test

.

Don

'

t

open

the gas line stop valves

.

Apply nitrogen gas pressure of

psi (

MPa

.

550

3.8

)

Check

for

any

gas

leakage

at

the

flare

nut connections

,

or brazed parts

by gas leak detector or foaming agent

.

Gas pressure doesn’t decrease is OK.

After

the

air

tight

test

,

release

nitrogen gas.

6. Vacuum

pumping

and

charge

refrigerant

Vacuum

pump

-0.101MPa

(-760 mmHg)

manifold gauge

Charge hose

(for R410A)

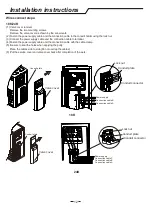

Piping insulation procedure

Connect pipes using different-diameter joint

Insulation

(

)

field-supplied

(

6

)

After finishing connecting the refrigerant pipes, keep it warm with

the insulation material like figure right.

·

For outdoor unit side, surely insulate every piping including valves.

·

Cover piping joints with pipe cover.

·

Using piping tape, apply taping starting from the entry of

outdoor unit. Fix the end of piping tape with adhesive tape.

-

Fix the end of piping tape with adhesive tape.

-

When piping has to be arranged through above ceiling, closet or area

where temperature and humidity are high, wind additional commercially

sold insulation for prevention of condensation.

Clamp(field-supplied)

Insulation (field-supplied)

Refrigerant pipe

(field-supplied)

(1) Remove the service port cap of the stop valve on the gas pipe

side of the outdoor unit.

(2) Connect the manifold gauge and vacuum pump to the service port

of the stop valve on the gas pipe side of the outdoor unit.

(3) Run the vacuum pump. (Work for more than 15 minutes.)

(4) Check the vacuum with the gauge manifold valve, then close the

gauge manifold valve and stop the vacuum pump.

(5) Leave it as is for one or two minutes. Make sure the pointer of the

manifold gauge remains in the same position. Confirm that the

pressure gauge shows -14.7 psi(-0.101MPa or -760mHg).

(6)Remove the manifold gauge quickly from the service port of the

stop valve.

(7) After refrigerant pipes are connected and evacuated, fully open

all stop valves on both sides of gas pipe and liquid pipe.

(8) Open adjusted valve to add refrigerant

(

must be refrigerant

is

liquid

).

(9) Tighten the cap to the service port .

(10) Retighten the cap.

(11) Leak test foam with halogen leak detector to check the flare nut

and brazing Carolina Department leaks. Use foam that not

generate ammonia (NH3) in the reaction.

9

5.

Air

tight test

If the diameter of connection pipe does not match the port size of outdoor unit, select proper different-

diameter joints in the accessory according to the following table.

Name

Qty

Purpose

1

Change pipe diameter from

1/4(6.35) to 3/8(9.52)

1

Change pipe diameter from

3/8(9.52) to 5/8(15.88)

1

Change pipe diameter from

3/8(9.52) to 1/2(12.7) mm

Outdoor unit

Different-diameter joint

indoor unit

Installation instructions

Summary of Contents for 18K

Page 17: ......