6

16575185_ed3

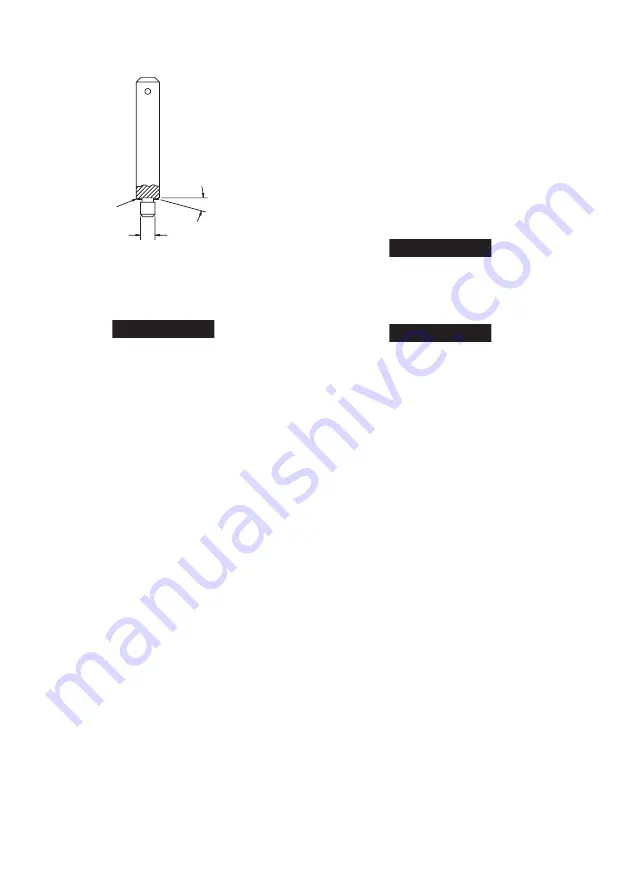

Needle Bearing Inserting Tool

Shoulder to

regulate depth

15°

Pilot to fit I.D. of bearing.

Length of pilot to be

approximately 1/8''

less than length of

bearing

(Dwg. TPD786)

11. Insert the Bit Holder (77) into the large end of the Clutch Housing

and push the output end through the Clutch Housing Bearing.

NOTICE

The following step has parts with a left-hand thread. Rotate the

components counterclockwise to tighten them.

12. Install the assembled Clutch Housing (75) over the clutch

components and thread it onto the Gear Case. Using a 1 1/16”

wrench on the flats of the Gear Case and the Clutch Housing

Spanner Wrench (Part No. TRH-478) in the clutch housing slot,

tighten the joint between 15 and 20 ft.-lbs. (20 and 27 Nm)

torque.

13. Invert the assembled tool in the vise jaws and lightly grasp the

flats on the Gear Case with the inlet end of the tool upward.

14. Insert a 5/8” dowel through the opening in the Back Cap (5), and

using the dowel as an alignment device, install the three

Muffler Elements (7) in the cavity of the Back Cap. Make certain

the notches in the outer edge of the Elements fit over

the memory chip pocket in the bottom of the Cap.

15. If the tool is equipped with a Memory Chip (8), install it (with the

leads entering first) in the pocket at the bottom of the Back Cap.

16. Make certain the tab on the inside edge of the

Back Cap Gasket (6) is aligned with the pocket for the Memory

Chip and install the Gasket, metal face leading, in the recess of

the Back Cap against the face with the cavity containing the

Muffler Elements.

17. Position the gasket end of the alignment dowel against the inlet

hub on the Motor Housing. Align the flats on the Cap with the

flats on the Housing. Orient the Back Cap to clear the Reverse

Lever (13) and slide the Back Cap Assembly off the alignment

dowel and onto the Motor Housing.

18. Insert the Push Rod (28) into the central hole in the inlet hub. The

Rod will enter the assembled motor and disappear from view

when released. Install the Shutoff Valve (14), small end first, in the

same opening.

19. The Exhaust Diffuser (9) has one slot that is longer than the other

five slots. The Back Cap has a short, molded stud projecting from

the inlet end. Place the Exhaust Diffuser against the Back Cap

with the long slot encircling the molded stud. Rotate the Diffuser

counterclockwise until the wall of the slot stops against the stud.

The exhaust ports are now in the full open position which will

provide maximum free speed.

20. If the Inlet Screen (12) required replacement, use a wooden

dowel to carefully push a new one into the Inlet Bushing (10).

21. If the Inlet Bushing Seal (11) is nicked or damaged, carefully

install a new one over the threads of the Inlet Bushing.

22. Thread the Inlet Bushing Assembly through the Diffuser and Back

Cap into the Motor Housing. Using a 1-3/16” wrench on the flats

of the Back Cap to keep it from turning, tighten the Inlet Bushing

between 15 and 20 ft.-lbs. (20 and 27 Nm) torque.

23. Remove the tool from the vise jaws and install the

Housing Grip (85) over the Clutch Housing.

24. Install the Grip Retaining Ring (88) in the external groove on

the Clutch Housing ahead of the Grip to retain the Grip on the

Housing.

25.

For Models with Quick Release Bit Holders

, place the

Bit Retaining Ball (78) in the hole through the wall of the

Bit Holder and slide the Bit Retaining Sleeve (80), large end

trailing, onto the Bit Holder. Slide the Retaining Sleeve

Spring (81) and Spring Seat (82) onto the Bit Holder and

secure the components by installing the Retaining Ring (83)

in the external groove at the output end of the Bit Holder.

NOTICE

The thread in the following step is a left-hand thread. Rotate the

component counterclockwise to tighten it.

26. Thread the Clutch Adjusting Hole Cover (89) onto the Clutch

Housing against the Housing Grip and hand tighten it between 2

and 6 ft.-lbs. (3 and 8 Nm) torque.

NOTICE

The following step has parts with a left-hand thread. Rotate the

components counterclockwise to tighten them.

27. Thread the Non-Rotating Bit Finder (84) or Clutch Housing

Cap (90) onto the Clutch Housing and hand tighten it

between 2 and 6 ft.-lbs. (3 and 8 Nm) torque.

Testing the Tool

Before placing the tool back in service, test the tool in a run down

application to determine if adjustments are necessary to satisfactorily

perform the operation. Since five interrelated adjustments can affect

tool performance, only experience, along with trial and error, can

dictate which adjustment or combination of adjustments will provide

the desired results.

The Clutch Spring (53 or 69), the clutch adjustment procedure, the

exhaust flow, the length of the Push Rod (28) and the length of the

Shutoff Valve (14) can individually or collectively have an effect

on torque and/or speed. Always try to make adjustments before

replacing or attempting to modify components. If adjustments are

unable to provide the desired torque, it may be necessary to install a

lighter or heavier Clutch Spring.

If the tool ratchets when operated but fails to shutoff, it may be

necessary to shorten the Push Rod. Only shorten the Push Rod in

small increments. Increments between 0.005” and 0.010”

(0.13 and 0.25 mm) are recommended.

If the tool stalls and does not shutoff, runs slower than normal or has

low power, the Shutoff Valve may require lengthening. To lengthen

the Shutoff Valve, grasp the stem between two pieces of rubber

or other non-slip, non marring material and rotate the molded nut

counterclockwise. Rotating the nut one half revolution will lengthen

the Valve approximately 0.009” (0.23 mm).

Should the stem of the Valve become bent, marred, nicked or

damaged in any way during the adjustment process, replace it.