18-CD37D1-2-EN

41

Installer’s Guide

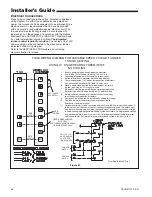

SEQUENCE OF OPERATION

Comfort Control call for heat (2-Stage Comfort Control)

Call for 1st Stage only:

W1 Comfort Control contacts close signaling the control mod-

ule to run its self-check routine. After the control module has

verified that the 1st Stage Pressure Switch contacts are open

and the Limit Switch(es) contacts are closed, the draft blower

will be energized.

As the induced draft blower comes up to speed, the Pressure

Switch contacts will close and the ignitor warm up period will

begin. The ignitor will heat for approx. 20 seconds, then the

Gas Valve is energized in 1st Stage to permit gas flow to the

burners.

The flame sensor confirms that ignition has been achieved

within the 4 second ignition trial period.

As the flame sensor confirms that ignition has been achieved,

the delay to fan ON period begins timing and after approx.

45 seconds the indoor blower motor will be energized at low

speed and will continue to run during the heating cycle.

Call for 2nd Stage after 1st Stage:

W2 Comfort Control contacts close signaling a call for 2nd

Stage Heat. After a 30 second delay, the induced draft blower

will be energized on high speed and the 2nd Stage Pressure

Switch contacts will close. The Gas Valve is energized in 2nd

Stage and the indoor blower motor in high speed.

2nd Stage satisfied, 1st Stage still called:

W2 Comfort Control contacts open signaling that 2nd Stage

Heating requirements are satisfied.

The induced draft blower is reduced to low speed allowing

the 2nd Stage Pressure Switch contacts to open and the Gas

Valve is reduced to 1st Stage. The indoor blower motor is

reduced to low speed.

1st stage satisfied:

W1 Comfort Control contacts open signaling that 1st Stage

heating requirements are satisfied. The Gas Valve will close

and the induced draft blower. The indoor blower motor will con-

tinue to run for the fan off period (Field selectable at 60, 100,

140 or 180 seconds), then will be de-energized by the control

module.

Comfort Control call for heat (1-Stage Comfort Control)

W1/ W2 (jumpered) Comfort Control contacts close signaling

a call for heat. 1st Stage sequence of operation remains the

same as above. 2nd Stage Heat will energize after the Stage

delay timer (10 minutes) has expired.

Comfort Control satisfied:

W1/ W2 (jumpered) contacts close signaling the control

module to close the Gas Valve. The induced draft blower is

switched to low speed and de-energized after the post purge

timer has expired. The indoor blower motor will continue to

operate after the flames are extinguished and then is switched

to low heat speed for the FAN-OFF period.

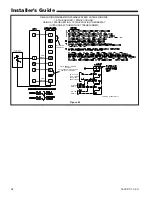

Start-up and Adjustment

Preliminary Inspections

▲

WARNING

!

ELECTRIC SHOCK HAZARD

DISCONNECT POWER TO THE UNIT BEFORE REMOV-

ING THE BLOWER DOOR. ALLOW A MINIMUM OF 10

SECONDS FOR IFC POWER SUPPLY TO DISCHARGE TO

0 VOLTS. FAILURE TO FOLLOW THIS WARNING COULD

RESULT IN PROPERTY DAMAGE, PERSONAL INJURY OR

DEATH.

With gas and electrical power “OFF”

1. Duct connections are properly sealed

2. Filters are in place

3. Venting is properly assembled

4. Blower door is in place

Turn the toggle switch on the main gas valve within the unit

to the “

OFF

” position (See Figures 54 - 56) . Turn the exter-

nal main gas shutoff valve to “ON”. Purge the air from the

gas lines. After purging, Check all gas connections for leaks

with a soapy solution —

DO NOT CHECK WITH AN OPEN

FLAME.

Allow 5 minutes for any gas that might have escaped

to dissipate. LP Gas being heavier than air may require forced

ventilation. Turn the toggle switch on the main gas valve within

the unit to the “ON” position.

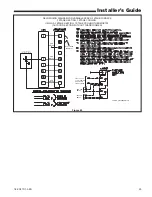

Lighting Instructions

▲

WARNING

!

BURN HAZARD

DO NOT ATTEMPT TO MANUALLY LIGHT THE BURNER.

FAILURE TO FOLLOW THIS WARNING COULD RESULT IN

PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

Lighting instructions appear on each unit. Each installation

must be checked out at the time of initial start up to insure

proper operation of all components. Check out should include

putting the unit through one complete cycle as outlined below.

Turn on the main electrical supply and set the comfort control

above the indicated temperature. The ignitor will automatically

heat, then the gas valve is energized to permit the flow of

gas to the burners. After ignition and flame is established, the

flame control module monitors the flame and supplies power

to the gas valve until the comfort control is satisfied.

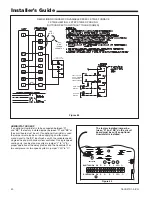

To shut off

For complete shutdown: Turn the toggle switch located on the

main gas valve inside the unit to the "OFF" position and the

external main gas shutoff valve to the “OFF” position (See

Figures 54-56). Disconnect the electrical supply to the unit.

▲

CAUTION

!

If shutoff is done during the cold weather months, pro-

visions must be taken to prevent freeze-up of all water

pipes and water receptacles.

Whenever your house is to be vacant, arrange to have some-

one inspect your house for proper temperature. This is very

important during freezing weather. If for any reason your

furnace should fail to operate damage could result, such as

frozen water pipes.

Control and Safety Switch Adjustments

LIMIT SWITCH CHECK OUT

The limit switch is a safety device designed to close the gas

valve should the furnace become overheated. Since proper

operation of this switch is important to the safety of the unit, it

must be checked out on initial start up by the installer.

To check for proper operation of the limit switches, set the ther-

mostat to a temperature higher than the indicated temperature

to bring on the gas valve.