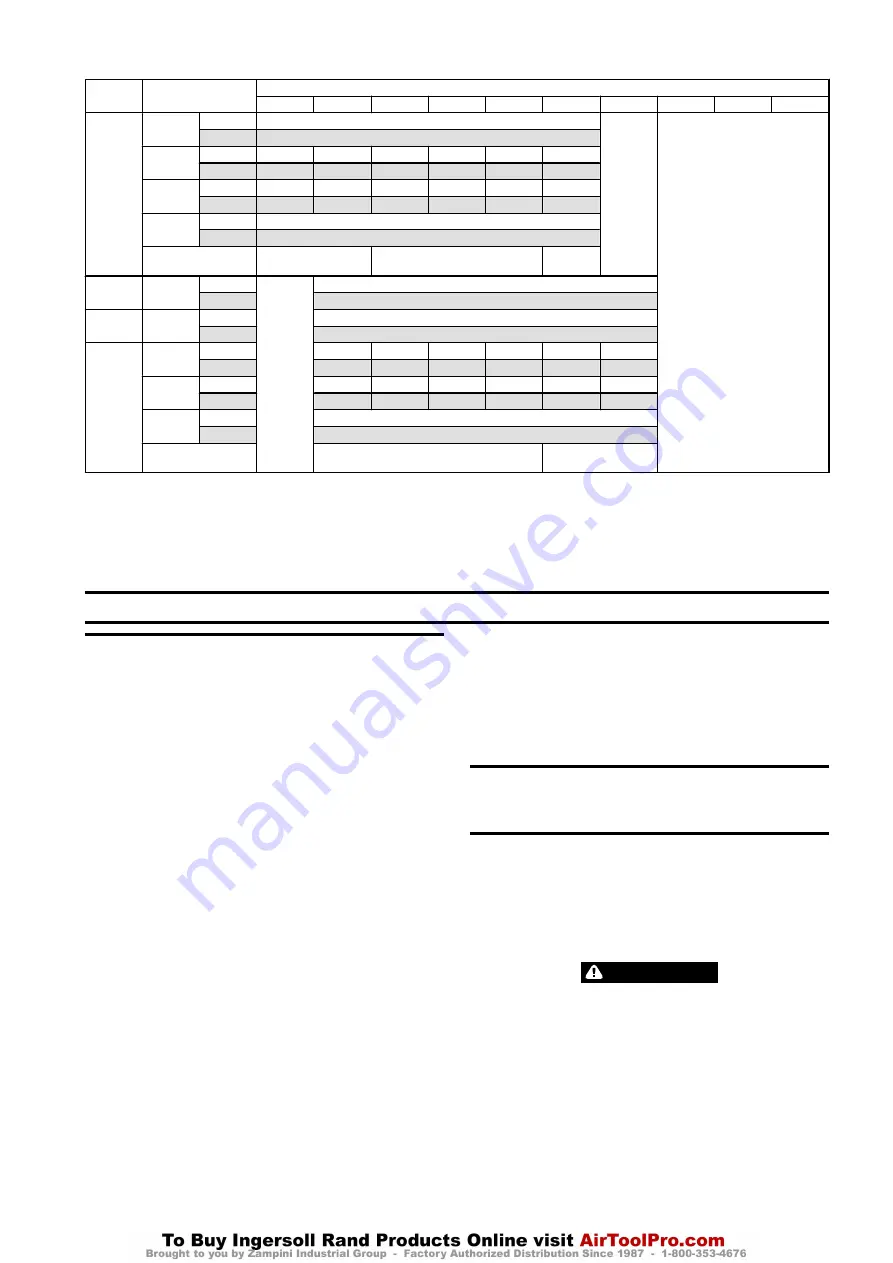

Table 8: Winch Bolt Hole Mounting Dimensions - Refer to Dwg. MHP0133 on page 11; A. Drum.

Models

Dimension

Drum Length (inches)

8

12

16

20

24

30

36

40

42

50

FA2.5i

(Note 1)

“A”

inch

20

Note 3

Note 3

mm

508

“B” *

inch

7

9

7.5

9

10

12

mm

178

229

190

229

254

305

“B” **

inch

6

8

7

8

9

11

mm

152

203

178

203

229

279

“C”

inch

0.6875

mm

17.5

Bolt Hole Qty each

Siderail

3

4

4

FA5i

“A”

inch

N/A

31.25

mm

794

FA2.5i-CE

“A”

inch

34.25

mm

870

FA5Ti/

FA5Ti-CE

(Note 2)

“B” *

inch

7.5

9

10

10.5

10

11

mm

190

229

254

267

254

279

“B” **

inch

6

6.25

8.5

9

12

14

mm

152

159

216

229

305

356

“C”

inch

0.8125

mm

20

Bolt Hole Qty each

Siderail

4

(4) 5

*

Drum with Manual or Automatic Drum Brake

**

Drum without Manual or Automatic Drum Brake

N/A

Not Available

Note 1:

30 and 36 inch Drum with Band Brake will require 5 bolts, without Band Brake 4 bolts.

Note 2:

20 inch Drum with Band Brake will require 5 bolts, without Band Brake 4 bolts.

36 inch Drum with Band Brake will require 6 bolts, without Band Brake 5 bolts.

Note 3:

Contact Factory

OPERATION

n

Winch Controls

The spring loaded, motor mounted, live air manual throttle control valve is supplied

as a standard feature on this winch. Optional remote throttle controls are available.

Reference model code on the winch data (name) plate and compare it to

“SPECIFICATIONS” on page 3, to determine your configuration. The throttle controls

provide operator control of motor speed and direction of drum rotation.

n

Winch Mounted Air Throttle

Refer to Dwg. MHP1809 on page 11, A. Haul-In; B. Exhaust Port; C. Lift Slider Handle

UP to Unlock; D. Payout; E. Air Inlet Port; F. Brake Release Port.

The winch control throttle valve is spring loaded, full flow air and mounts to the

motor rotary housing.

To operate control valve, place palm of hand on control knob and wrap fingers

around flange of sliding handle. Squeeze fingers, lifting sliding handle up to unlock

control handle. Shift control handle in desired direction to payout or haul-in wire

rope. As viewed from air motor end, move control throttle handle to the right

(clockwise) to payout wire rope and to the left (counterclockwise) to haul-in wire

rope. Avoid sudden movements of handle to ensure smooth operation of winch.

When released, handle will return to neutral or center position, sliding handle will

drop down to engage and lock control handle in place.

n

Remote Full Flow Air Throttle

Refer to Dwg. MHP2043 on page 13, A. To Brake; B. Threaded Ports.

Provides for remote mounting of winch control at a fixed location at up to 20 feet (6

metres) away from winch motor. Air hoses connect throttle to winch motor to

provide winch operation.

Move control throttle handle to the right (clockwise) to payout wire rope and to the

left (counterclockwise) to haul-in wire rope. Avoid sudden movements of control

valve to ensure smooth operation of winch.

n

Remote Pilot Pendant Throttle

Refer to Dwg. MHP2398 on page 13, A. Red - Air Supply; B. Green; C. Yellow; D.

Payout load; E. Haul-In Load.

Provides for remote winch control at distances of up to 66* feet (20 metres) away

from winch. The pilot pendant control throttle is a two function movable control

station for winch operation. Pilot pressure from pendant control activates winch

control valve. The winch control valve, located on winch motor, controls motor

speed and direction of drum rotation. Direction of drum rotation is determined by

the pendant lever/button depressed.

n

Remote Pilot Lever Throttle

Provides for remote winch control at distances of up to 66* feet (20 metres) away

from winch. The lever pilot control throttle is a fixed mounted lever control station

for winch operation. Pilot pressure from lever pilot control throttle activates winch

control valve. The winch control valve, located on winch motor, controls motor

speed and direction of drum rotation. Direction of drum rotation is determined by

the direction in which lever is shifted.

* For distances greater than 50 feet (15 metres) contact Ingersoll Rand Technical

Sales for control suitability.

n

Underwound Operation (optional feature)

Underwound operation allows wire rope haul-in or payout off the bottom of drum.

This is a special operation and requires a winch specifically designed for this usage.

n

Emergency Stop and Overload System

Emergency Stop and Overload System are standard on -CE winches.

Refer to Dwg. MHP2619 on page 11, A. Emergency Stop Button; B. Push Down to

Stop Winch Movement; C. Overload Valve Reset Button; D. Twist Red Button to Reset;

E. Overload Valve Adjustment Screw.

When emergency stop or overload valve is activated, winch drum rotation will

immediately cease.

CAUTION

•

If winch continues to move (payout load) after emergency stop activates,

brake(s) are not holding load and may require adjustment or repair.

When control valve senses a preset pressure difference between ports, a pilot signal

is sent to stop flow of air, winch drum rotation will immediately cease.

n

Emergency Stop

Emergency stop device is located on the control valve. When activated, winch drum

rotation will immediately cease. To activate emergency stop, depress (push down)

red palm valve, located on top of control valve.

Form MHD56434 Edition 6

7