Operation & Maintenance Manual

Safety

16

Book 22482517 (7-09) Rev A

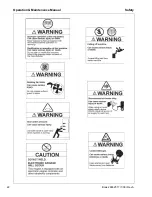

Transport

When loading or transporting machines ensure that the specified lifting and tie down points are

used.

When loading or transporting machines ensure that the towing vehicle, its size, weight, towing

hitch and electrical supply are all suitable to provide safe and stable towing at speeds either,

up to the legal maximum for the country in which it is being towed or, as specified for the

machine model if lower than the legal maximum.

Do not exceed gross vehicle weight rating.

Before towing the machine, ensure that:-

•

the tires and towing hitch are in a serviceable condition.

•

the canopy is secure.

•

all ancillary equipment is stored in a safe and secure manner.

•

the brakes and lights are functioning correctly and meet necessary road traffic

requirements.

•

break-away cables/safety chains are connected to the towing vehicle.

The machine must be towed in a level attitude in order to maintain correct handling, braking

and lighting functions. This can be achieved by correct selection and adjustment of the vehicle

towing hitch and, on variable height running gear, adjustment of the drawbar.

1. Make sure wheels, tires and tow bar connectors are in safe operating condition

and tow bar is properly connected before towing.

2. When parking always use the handbrake and, if necessary, suitable wheel

chocks.

Safety chains/connections and their adjustment where fitted:

Ensure that the breakaway cable is securely coupled to the trailer and also to a substantial

point on the towing vehicle.

Ensure that the cable length is as short as possible, while still allowing enough slackness for

the trailer to articulate without the handbrake being applied.

Loop the chains onto the towing vehicle using the towing vehicle hitch as an anchorage point,

or any other point of similar strength.

Ensure that the effective chain length is as short as possible while still allowing normal

articulation of the trailer and effective operation of the breakaway cable.

Summary of Contents for Doosan HP750WCU-T2

Page 2: ...2...

Page 6: ...6 Always use Ingersoll Rand Replacement parts...

Page 7: ...Book 22482517 7 09 Rev A 7 Foreword...

Page 11: ...Book 22482517 7 09 Rev A 11 Safety...

Page 18: ...Operation Maintenance Manual Safety 18 Book 22482517 7 09 Rev A...

Page 19: ...Safety Operation Maintenance Manual Book 22482517 7 09 Rev A 19...

Page 20: ...Operation Maintenance Manual Safety 20 Book 22482517 7 09 Rev A...

Page 22: ...Operation Maintenance Manual Safety 22 Book 22482517 7 09 Rev A...

Page 23: ...Safety Operation Maintenance Manual Book 22482517 7 09 Rev A 23...

Page 24: ...24 Book 22482517 7 09 Rev A...

Page 26: ...Operation Maintenance Manual Safety 26 Book 22482517 7 09 Rev A...

Page 27: ...Book 22482517 7 09 Rev A 27 Noise Emission...

Page 33: ...Book 22482517 7 09 Rev A 33 Section C General Data...

Page 36: ...36 Book 22482517 7 09 Rev A Always use Ingersoll Rand Replacement parts...

Page 37: ...Book 22482517 7 09 Rev A 37 Section D Operating Instructions...

Page 47: ...Book 22482517 7 09 Rev A 47 Section E Maintenance...

Page 60: ...60 Book 22482517 7 09 Rev A Always use Ingersoll Rand Replacement parts...

Page 61: ...Book 22482517 7 09 Rev A 61 Section F Lubrication...

Page 64: ...Operation Maintenance Manual Lubrication 64 Book 22482517 7 09 Rev A Torque Setting Table...

Page 65: ...Lubrication Operation Maintenance Manual Book 22482517 7 09 Rev A 65 Torque Setting Table...