3

ADJUSTMENTS

Accessory Installation

Always turn off the air supply and disconnect the air

supply hose before installing, removing or adjusting any

accessory on this tool or before performing any

maintenance on this tool.

For Plain–Type Retainer No. HH1–1190

Grasp Retainer and remove Lock Spring from the Retainer

groove. Remove Retainer from Barrel. Raise chisel until the

oval, integral collar on the chisel shank clears the alignment

grooves inside the Retainer. Rotate the chisel 90

°

.

The chisel can now be removed from the front of the Retainer.

To install the chisel, insert the shank of the chisel into the

front of the Retainer until the chisel can be turned 90

°

,

allowing the oval, integral collar on the chisel shank

to drop and rest on the shoulder in the retainer.

Attach the Retainer to the Barrel by aligning the slot in the

Retainer with the groove in the Barrel. Insert the Lock Spring

through the slot in the Retainer body and push the Lock

Spring around the Barrel and Retainer until the Retainer is

secured to the Barrel.

For Rubber Buffered Type Retainer No. HHW1–300 (for

use with threaded barrel)

Grasp the Retainer (28) and unscrew it from the Barrel (17)

against the pressure of the Retainer Lock Spring (27).

Remove the buffer and the chisel from the rear of the Retainer.

The Buffer will split to allow the use of a wide chisel.

To install a wide chisel, pass the shank of the chisel through

the hole in the Retainer and by opening the split in the buffer,

fit it around the chisel making sure that the shoulder of the

chisel locates in the large counter bore of the buffer. Slide the

assembly into place in the threaded end of the Retainer.

Moil point and narrow chisels can be removed and

installed without removing the buffer from the Retainer.

Align the end of the chisel with the Nozzel (21) and thread the

retainer onto the Barrel. Tighten the Retainer clockwise on

the Barrel until the Retainer Lock Spring can be seen or heard

to locate in place in the recess in the barrel thread. Check

correct engagement by trying to rotate the Retainer. If

significant resistance is felt, the Retainer Lock Spring is

correctly engaged. If no significant resistance is felt, rotate

the Retainer until Retainer Lock Spring engages properly.

PLACING TOOL IN SERVICE

Hammers are coated inside and out with rust–resisting oil

before leaving the factory. Before using the Hammer, remove

this oil by dipping the tool in a suitable cleaning solution to

wash the oil from the exterior. Pour about 6 cc of a suitable

cleaning solution into the air inlet and attach the air hose.

Insert a Chisel into the Hammer and while holding the chisel

blade against the work or a relatively solid object such as a

plank or timber, operate the tool for about 15 seconds. Dry

the tool immediately after cleaning, pour 3 cc of

Ingersoll–Rand No. 10 Oil into the air inlet and again operate

the tool for 5 seconds to lubricate all working parts.

LUBRICATION

Ingersoll–Rand No. 10

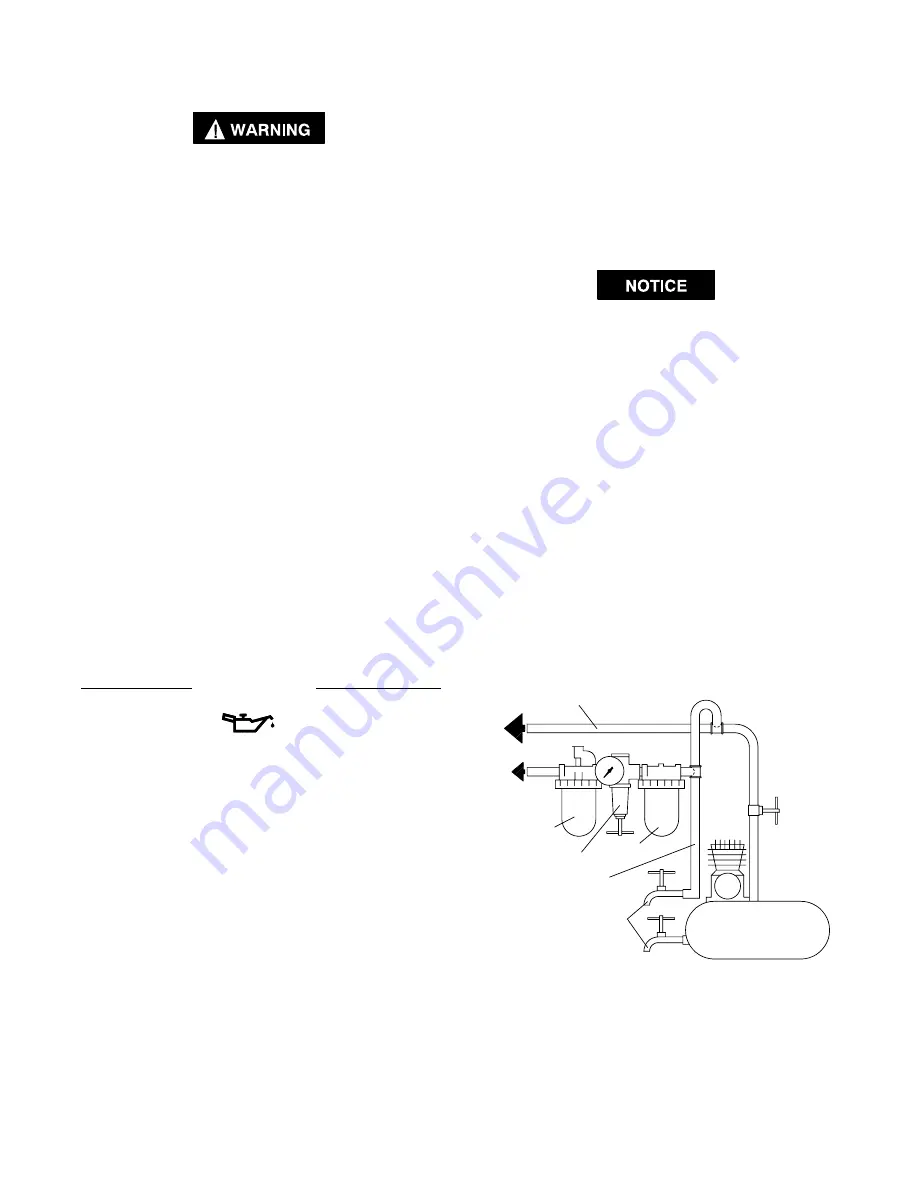

Always use an air line lubricator with these tools.

We recommend the following Filter–Lubricator–Regulator

Unit:

For USA – C18–03–FKG0–28

Before attaching the air hose, place about 3 cc of

Ingersoll–Rand No. 10 Oil into the air inlet. This should be

done each day, even when an air line lubricator is used.

During the working day, check the tool to ensure that the

retainer components are lubricated.

After each two or three hours of operation, if an air line

lubricator is not used, disconnect the air hose and pour about

3 cc of Ingersoll–Rand No. 10 Oil into the air inlet of the tool.

If the action of the Hammer becomes sluggish, pour about

3 cc of a suitable cleaning solution into the air inlet and run

the tool for not more than thirty seconds. Immediately after

flushing the tool, pour about 3 cc of Ingersoll–Rand No. 10

Oil into the air inlet and run the tool for about thirty seconds

to lubricate internal parts.

Before storing a Hammer or if the Hammer is to be idle

for a period exceeding twenty–four hours, pour about

3 cc of Ingersoll–Rand No. 10 Oil into the air inlet and operate

the tool for 5 seconds to coat the internal parts with oil.

MAIN LINES 3 TIMES

AIR TOOL INLET SIZE

TO

AIR

SYSTEM

TO

AIR

TOOL

LUBRICATOR

REGULATOR

FILTER

BRANCH LINE 2 TIMES

AIR TOOL INLET SIZE

DRAIN REGULARLY

COMPRESSOR

(Dwg. TPD905–1)