Copyright © 2003-2005 InfoSight Corporation All Rights Reserved

Page 31 of 39

LASER HAZARD CLASSIFICATIONS

The intent of laser hazard classification is to provide clear distinction of the lasers’ properties and hazards to users so

appropriate protective measures can be taken. Classification is based on the maximum output available for the intended

use. Specific labeling requirements indicate that the class of the laser as well as the emission wavelength(s) and any

other applicable precautionary instructions must be included on any signage. Laser classification is also used for

determining requirements for medical surveillance for those individuals working with and around lasers.

The Federal United States laser safety standard [21 CFR 1040.10], the ANSI standard [ANSI Z136.1], as well as the

international standard [EN 60825], divide lasers into five distinct hazard categories. These classes are based upon the

combination of wavelength range, power, and emission duration, which are used to determine the level of risk and the

potential to cause biological damage to the eye or skin. The definitions compiled from ANSI Z136.1 are as follows:

Class 1

:

Any laser, or laser system containing a laser, with wavelength ranges from Ultraviolet through Far Infrared

(180 nm – 100,000 nm +), that cannot emit laser radiation levels exceeding Class 1 Accessible Emission Limits (AEL) as

defined by ANSI Z136.1. For example this would compute to exposure (for an eight-hour period) for a 488 nm laser of no

greater than 0.2 mW. Basically, the laser radiation level emitted by a device classified as Class 1 produces no hazard

whatsoever to the user during normal operation. Presently, Class 1 lasers and laser systems are exempt from all control

measures. The Class 1 designation does not apply during times of maintenance or service where the safety controls of

the device are defeated or otherwise removed. The Class 1 environment resumes once the device is returned to its

original state with all safety devices properly reconnected.

Class 2:

This classification applies only to continuous wave (CW) and repetitive-pulse lasers and laser systems of the

visible part of the electromagnetic spectrum (400 – 700 nm) that exceed Class 1 levels, but do not exceed an average

radiant power of 1 mW.

Class 3a:

Lasers and laser systems that have an accessible output between one and five times the Class 1 AEL for

wavelengths shorter than 400 nm or longer than 700 nm, or less than five times the Class 2 AEL for wavelengths

between 400 and 700 nm. Lasers of this class have intermediate power ranges of 1 - 5 mW.

Class 3b:

Lasers and laser systems having the power range between 5 - 500 mW. This applies to lasers with wavelength

ranges from Ultraviolet through Far Infrared (180 nm – 100,000 nm +). These lasers or laser systems can produce a

hazard if viewed directly, and may produce an eye hazard when viewing diffuse reflections off of a shiny surface at angles

of less than 5 degrees from the source, however Class 3b lasers should not produce a hazardous diffuse reflection from

a matte (not shiny) surface.

Class 4:

Lasers and laser systems having power greater than 500 mW. This applies to lasers with wavelength ranges

from Ultraviolet through Far Infrared (180 nm – 100,000 nm +). This class of laser poses the greatest hazard, and any

and all precautions should be taken to protect oneself from exposure to direct or diffuse laser radiation. Direct exposure

to the eye from this class of laser can cause permanent damage. Stray beams are potential fire hazards and combustible

material should be kept out of beam paths at all times.

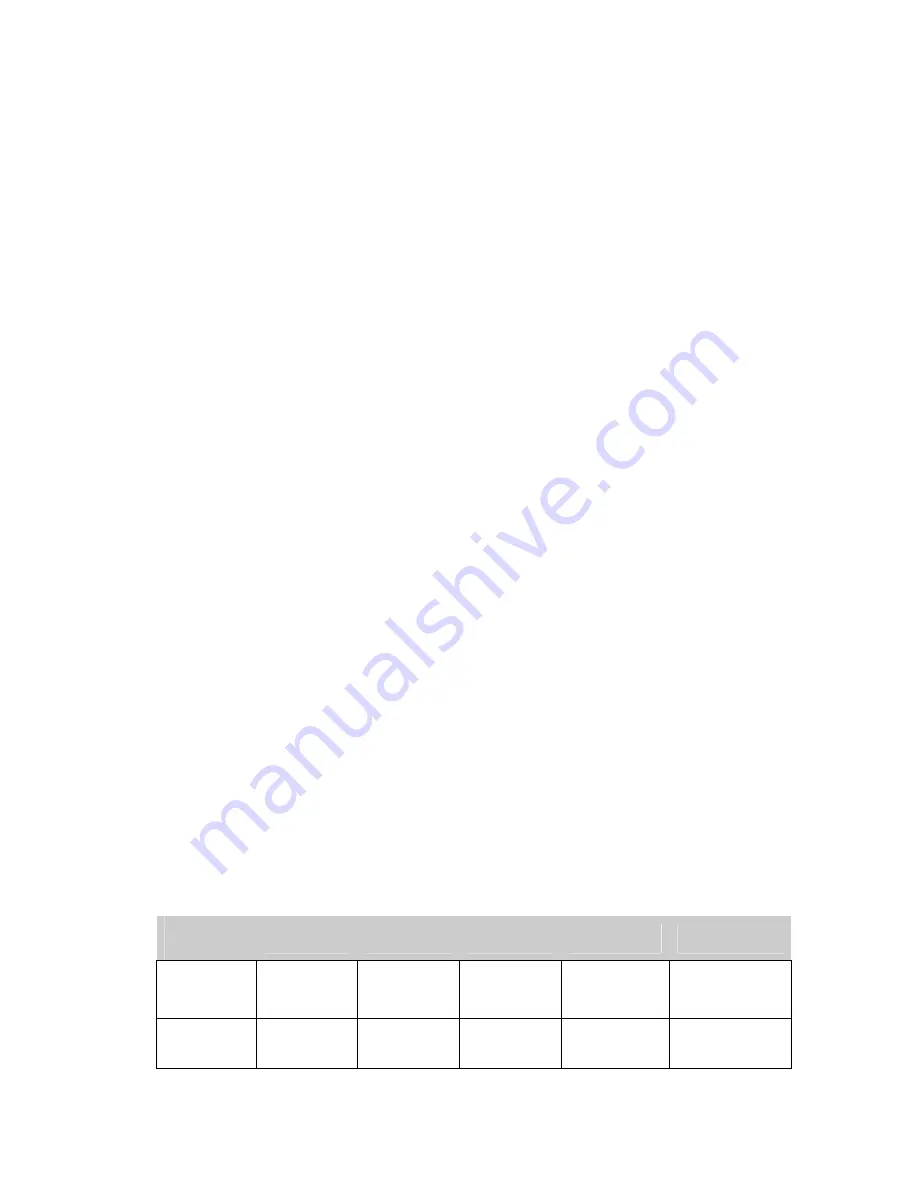

1.3 CONTROL MEASURES FOR LASER CLASSIFICATIONS

C o n t r o l

M e a s u r e

C l a s s 1

C l a s s 2

C l a s s 3 a

C l a s s 3 b

C l a s s 4

Activation

Warning

Systems

No

requirement.

No

requirement.

No

requirement.

Should have.

Shall have.

Indoor Laser

XE Optics

Lasers

No

requirement.

No

requirement.

No

requirement.

Shall have.

Nominal Hazard

Zone analysis

Shall have.

Nominal Hazard

Zone analysis