8

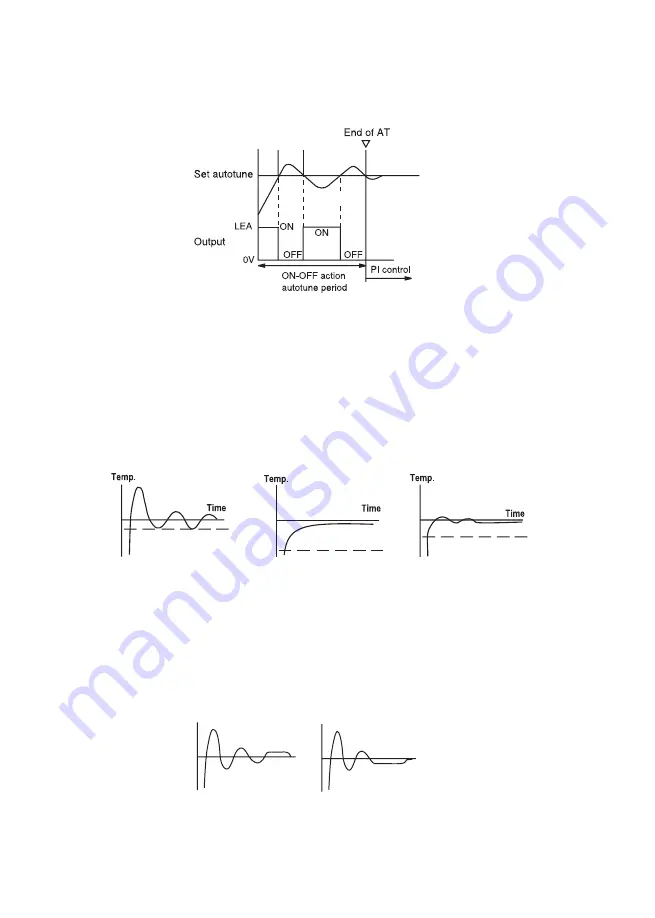

In some cases the autotune function does not perform well or does not perform at all:

1. The system is affected by process disturbances external to the control loop during autotuning (windows opened, load variation)

2. The system is very dynamic. This is the case in which the heating or cooling power is too high for the volume of room regulated.

Considering the conditions for autotuning cycle, some large overshoots can be verified.

3. The system is very insulated and cannot cool down (heating season) or heat up (cooling season) in a timely manner. For such

systems the autotuning cycle would take a very long time to complete with questionable results.

During autotuning the period of oscillations, overshoots and undershoots are measured. At the end of the cycle Bp, Ti parameters

are calculated.

aPPEnDiX 2

Manual parameters setting

Proportional band

The width of the proportional band depends of the dynamics of the system. The first question to ask is, how strong must my

output be to eliminate the error between the setpoint and temperature ?

The larger the proportional band (low gain), the less reactive the process. A proportional band too large, however, can lead to

process wandering or sluggishness. The smaller the proportional band (high gain), the more reactive the output becomes. A

proportional band too small, can lead to over-responsiveness leading to process oscillation.

A proportional band with is correct in width approaches the setpoint as fast as possible while minimizing overshoot. If a faster

approach to setpoint is desired and process overshoot is not a problem, a smaller or narrower proportional band may be used.

If process overshoot cannot be tolerated and the approach to setpoint does not have to be quick, a larger proportional band

can be choosen.

integral time

With proportional band alone, the process tend to reach a point away from setpoint. This offset is due to the difference betwe-

en the output needed to mantain setpoint and the ouptut of the proportional band at setpoint.

In the case of 2 pipe system with MAr=5V (50% of proportional band) if it is necessary a voltage different from 50% to mantain

the setpoint, the offset is the difference between them.The integral action eliminates this difference.

The integral action eliminates this difference by adding or substracting a value to the proportional action alone.

Integral time is the speed at which the controller corrects for offset. A short integral time means the controller corrects for offset

quickly. If the integral time is too short, the controller would react before the effect of previous output shift, due to dead time or

lag time, could be sensed causing oscillations.

A long integral time means the controller corrects the offset over a long time. If the integral time is too long, the offset will remain

for some time causing slow responding or sluggish control.

Proportional band with

correct width

Proportional band

too small

Proportional band

too large