Maintenance & Repair

45

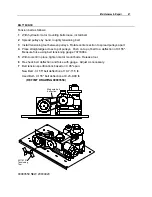

AIR/OIL COALESCER

The air/oil coalescer employs an element permanently housed within a canister on top of the air

end assembly. This is a single piece unit that requires replacement when it fails to remove the

oil from the discharge air, or pressure drop across it exceeds 15 PSI. Dirty oil clogs the element

and increases the pressure drop across it.

1

Shut down compressor and wait for complete blow down (zero pressure). Also, completely

drain air tank.

2

Remove output control valve (1).

3

Remove coalescer element (2) by turning element counterclockwise.

4

Clean output control valve (1) and the contact surfaces of the coalescer.

5

Clean hose end orifices (3).

6

Lubricate coalescer o-ring. Replace coalescer element (2). Rotate element clockwise by

hand until element contacts seal. Rotate element approximately one more turn clockwise

with band wrench near top of element.

7

Replace o-ring (5) between coalescer and output control valve.

8

Replace seals of output control valve with a new set. When assembling, leave nut M6 (6)

about 2 mm off the valve cover. (DO NOT TIGHTEN!)

9

Replace assembled valve.

10

Tighten screws, alternating sides, to a common tightness.

11

Run system. Check for leaks.