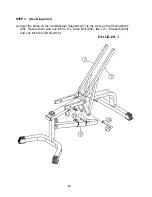

STEP 3 (See Diagram 3)

A.) Attach the Lat Bar Frame (#23) to the Lat Bar Base (#10). Secure it with two M10 x 2

½” Allen Bolts (#22), four

∅

¾” Washers (#5), and two M10 Aircraft Nuts (#6).

B.) Slide the Weight Post (#31) onto the Lat Bar Frame (#23).

C.) Slide two Rubber Bumpers (#54) onto the weight posts. Attach two short Olympic

Sleeves (#33) onto the posts. Secure them with two

∅

2” Spring Clips (#34).

DIAGRAM 3

6