I-Control manual

page 34

I-Control software update

The I-Control software can easily be updated if necessary. To update, a micro Sd memory card is required. The Sd

card must be FAT16 or FAT32 formatted. The capacity of the Sd card can be up to 32GB.

Updating the I-Control is as follows:

1

Using your PC, copy the update file to the micro Sd

card. The file should be placed in the root directory and

not in a folder on the Sd card.

2

Make sure there is no backup file from any previous

backup on the Sd card. Delete any previous backup

files, which are those with .BCK and .USED extensions.

3

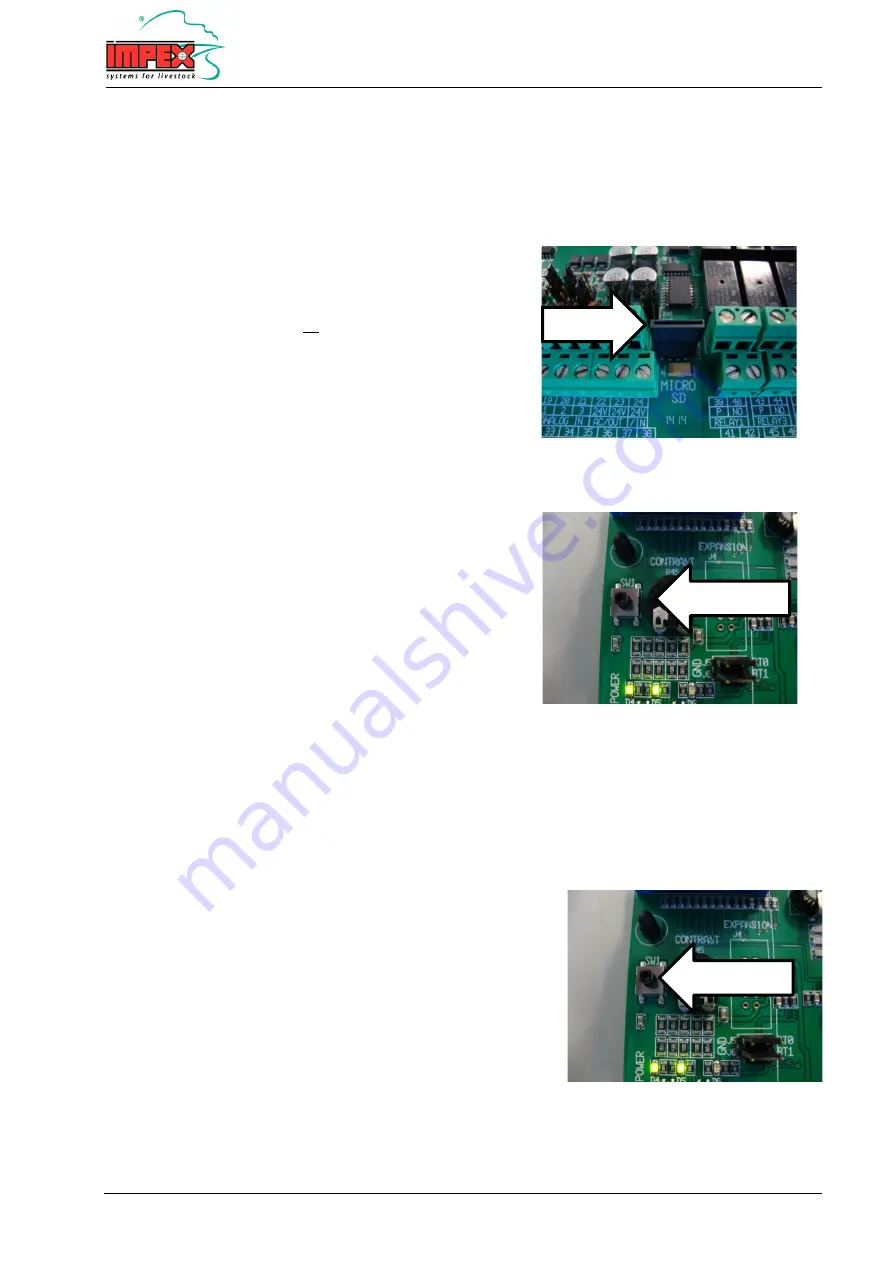

Insert the Sd card into the connector. See upper

picture.

4

Press the SW1 button located on the bottom printboard

of the I-Control. See lower picture.

5

The I-control writes all the set functions on the Sd card,

which is indicated by the flashing ADDR-led.

6

Thereafter, the I-control starts the boot program and

the update is performed. The display will show this

process.

7

Once the update is completed, the user program

automatically starts.

8

Thereafter, the functions saved on the Sd card are

replaced in the relevant functions. Any "new" features

in the new software will be set to the default.

9

The I-control is updated and ready for use.

Restoring factory settings

To reset the settings to the factory settings, proceed as follows:

1

Turn off the power.

2

Press the SW1 button on the bottom printboard and keep it

pressed while the power is turned on.

3

Keep this button pressed for at least 30 seconds until the

run-indicator blinks at one second intervals.

4

The factory settings are now restored.

Sd-card

SW1 button

SW1 button