13

OPERATING INSTRUCTIONS & MAINTENANCE

If you restart the compressor and the overload

cutout activates again, switch off the

compressor, remove the plug from the mains

and have your compressor checked by a

qualified service agent.

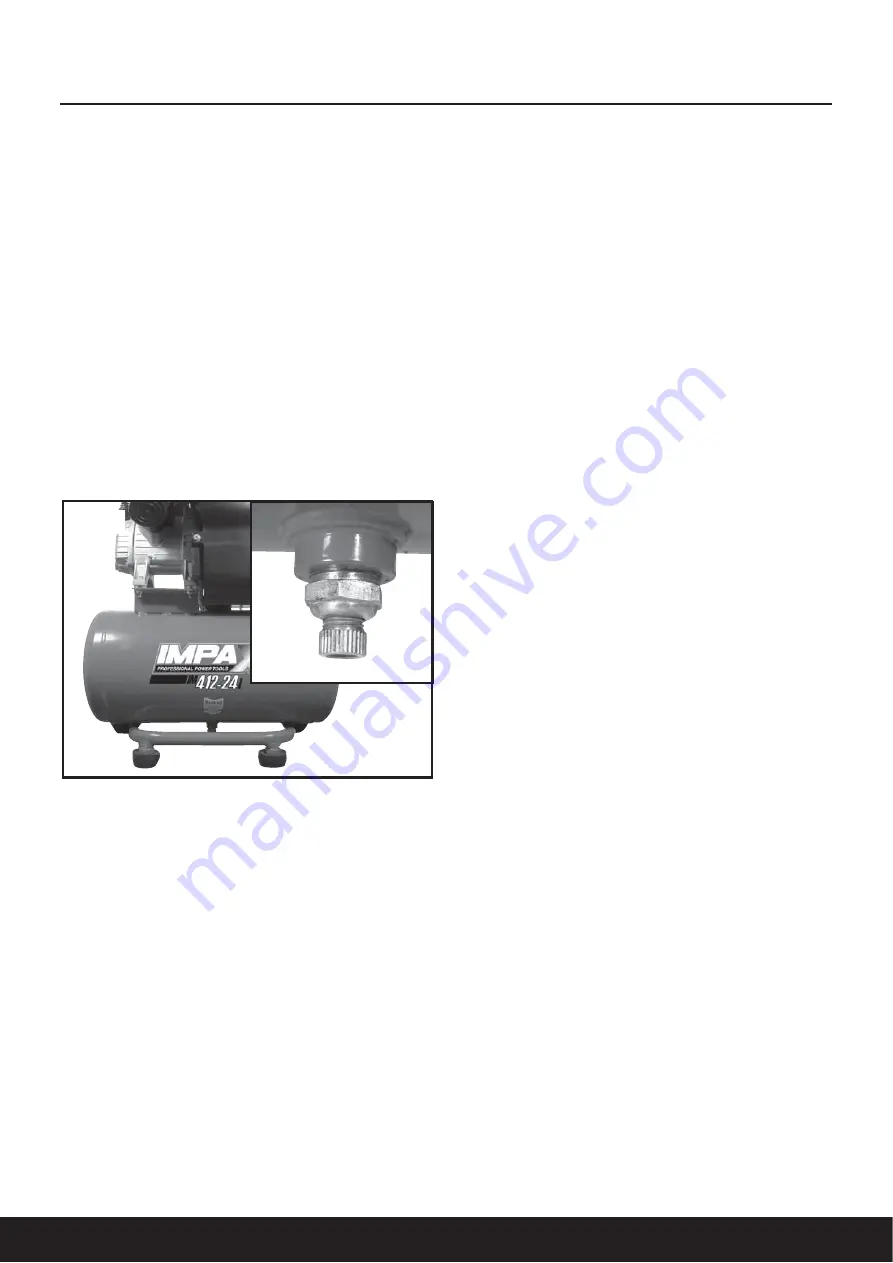

Draining the Reservoir

Caution!

It is important to drain the reservoir

before storage.

Switch the air compressor off, by pressing down

the red On/Off button, and remove the plug from

the mains supply.

Place a suitable container beneath the

compressor to catch any condensation.

Carefully undo the drain valve anti-clockwise

until you hear a hissing noise, this is the

reservoir depressurising (Fig 17).

When the gauge indicates zero and the hissing

has stopped, tighten the drain outlet nut again.

Oil Changing

For changing the pump oil, be sure to do the

following:

1. Turn the unit off and unplug the power cord

from the receptacle.

2. Allow the compressor time to cool if it has

been in operation.

3. Open the drain valve to bleed all air from the

tank.

4. Close the drain valve.

5. Remove the oil fill cap on the pump.

6. Remove the sight glass with a box end

wrench or socket. Drain the oil into a suitable

container and dispose of properly. The

compressor may need to be tipped slightly

towards the drain hole to allow all of the oil

to drain.

7. Reattach the sight glass. When

re-assembling. Be sure the gasket is between

the sight glass and the pump crankcase.

8. Refill the compressor pump with an air

compressor oil such as SAE-30 non-

detergent (API CG/CD Heavy Duty) oil at

slow intervals until the oil reaches the center

of the red circle in the sight glass. Use a

SAE-10 during extreme winter conditions.

Maintenance

Important:

Before carrying out any

maintenance, always disconnect the

compressor from the mains supply, drain the air

receiver and, if necessary, allow the machine to

cool down before starting work.

1.The compressor must be drained completely

by loosening the water drain cock. Drain the air

receiver tank daily after use.

2. The air filter can be removed for either

cleaning or replacing. Clean the air filter element

after every 100 hours of use or if low pressure is

experienced. Replace the air filter after 200

hours of use. Note: Under no circumstances

should the compressor be operated with the air

filter removed.

3.Cleaning and maintaining the compressor

regularly will give a long and trouble free life.

Before long term storage it is advisable to give

the compressor a thorough clean. This should

include the removal of all fitted accessories. Do

not use any solvents as these can damage

plastic parts. Only use a clean cloth dampened

with warm soapy water. Any metal parts should

be given a wipe with a light machine oil to

prevent rusting.

Caution.

Water must never come into contact

with the compressor.

Fig 17