31

In case of ΔT > 35 °C, the boiler lowers the

power to avoid surpassing that value. When

this status is on, the flow temperature symbol

flashes.

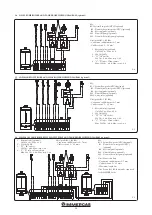

3.8 CONTROL FUNCTION AIR FLOW

RATE.

With ignition request, before the start of the fan,

the condition of the pressure switch contact is ve-

rified. If this is detected closed, the continuation

of the cycle is prevented.

After a delay time of about 50 seconds, there is

a permanent block and fault “0A4” is signalled.

If the detected contact is open, the fan activates

at the “air pressure switch control” speed (3300

rpm). When the pressure switch is closed, the fan

switches to the ignition speed, and the ignition

cycle continues ignoring the pressure switch

condition.

If during operation at the “air pressure switch

control” speed (3300 rpm) the pressure switch

does not close, after a time of about 50 seconds

there is a permanent block and the fault “0A4”

is signalled.

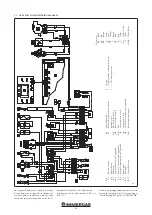

3.9 PROGRAMMING THE BOILER P.C.B.

The boiler is prepared for possible programming

of several operation parameters. By modifying

these parameters as described below, the boiler

can be adapted according to specific needs.

- Access programming by pressing and holding

down buttons “B” and “C”.

3-3

3.7 TROUBLESHOOTING.

N.B.:

maintenance interventions must be carried

out by an authorised company (e.g. Immergas

After-Sales Technical Assistance Service).

- Smell of gas. Caused by leakage from gas circuit

pipelines. Check sealing efficiency of gas intake

circuit.

- Repeated ignition blocks. No gas, check the

presence of pressure in the network and that

the gas adduction valve is open. Incorrect

adjustment of the gas valve, check the correct

calibration of the gas valve.

- Irregular combustion or noisiness. It may be

caused by: a dirty burner, incorrect combustion

parameters, intake-exhaust terminal not cor-

rectly installed. Clean the above components

and ensure correct installation of the terminal,

check correct setting of the gas valve (Off-Set

setting) and correct percentage of CO

2

in flue

gases.

- The over temperature safety thermostat, the

flow probe or the return probe are triggered

frequently. It can depend on the lack of water in

the boiler, little water circulation in the system

or blocked pump. Check on the manometer

that the system pressure is within established

limits. Check that the radiator valves are not

closed and also the functionality of the pump.

In addition:

- check that the exchanger safety thermostat

has not intervened. If it has, check the integrity

of the module and ceramic fibre panel, replace

the cover gasket of the manifold and reset the

thermostat by pressing the specific button.

- check that the exchanger safety thermostat

has not intervened. If it has, check the integrity

of the module and ceramic fibre panel, replace

the cover gasket of the manifold and reset the

thermostat by pressing the specific button

Also check the integrity of the thermofuse, and

if it has been triggered it will be necessary

to check the integrity of the module and the

flue circuit.

- Drain trap clogged. This may be caused by

dirt or combustion products deposited inside.

Check, by means of the condensate drain cap,

that there are no residues of material blocking

the flow of condensate.

- Heat exchanger clogged. This may be caused by

the trap being blocked. Check, by means of the

condensate drain cap, that there are no residues

of material blocking the flow of condensate.

- Noise due to air in the system. Check opening

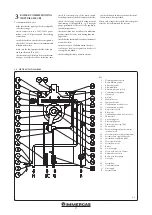

of the special air vent valve cap (Fig. 1-25 Ref.

23). Check that system filling and air bleeding

has been performed according to the require-

ments.

- Noise due to air inside the condensation

module. Use the manual air vent valve (Fig.

1-25 Ref. 13) to eliminate any air present in the

condensation module. When the operation has

been performed, close the manual vent valve.

- No DHW is produced. The boiler is equipped

with a function that automatically recognises

when there is an optional DHW probe, and an

anomaly is reported if there is a failure affecting

the DHW NTC probe. If there is a power out-

age, or if the boiler is switched off and back on

again during the failure, it will not be possible

to detect said failure, but it will, however, be

recorded in the errors anomaly records.

- Scroll through the parameters by pressing the

+ and - heating adjustment buttons,

- Change the parameter by pressing the + and -

DHW adjustment buttons.

- Save the parameters by switching from one

parameter to the next or by pressing “B”.

- Exit the programming mode by pressing and

holding down buttons “B” and “C”, or wait

approximately 2 minutes without touching the

buttons. The boiler will then run a self-diag-

nosis of the parameters by displaying “PARA”

followed by “Auto”.

- While the value of a parameter is being dis-

played, press “B” quickly to see the code again.

3-4

3-5

3-6

Summary of Contents for VICTRIX PRO 35 2ErP

Page 1: ...IE Instruction and warning book VICTRIX PRO 35 55 2 ErP 1 041662ENG...

Page 2: ......

Page 38: ...38 3 15 1 6 8 9 9 12 12 10 11 13 13 13 13 A A Rif A 7 7 Ref A...

Page 49: ...49...

Page 50: ...50...

Page 51: ...51...