8

INS

TALLER

U

SER

M

AINTEN

AN

CE

TECHNI

CI

AN

TECHNI

CAL

D

AT

A

OK

1

It is not permitted to install boilers that are removed and decommissioned from other systems.

The manufacturer declines all liability for damages caused by boilers removed from other systems or for any non-conformities

of such equipment.

Check the environmental operating conditions of all parts relevant to installation, referring to the values shown in the techni-

cal data table in this booklet.

Installation of the appliance when powered by LPG or propane air must comply with the rules

regarding gases with a greater density than air (remember, as an example, that it is prohibited

to install plants powered with the above-mentioned gas in rooms where the floor is at a lower

quota than the country level).

If installing a kit or servicing the appliance, always empty the system’s domestic hot water circuit first so as not to compromise

the appliance’s electrical safety (Parag. 2.9, 2.10).

Always disconnect the appliance from voltage and, depending on the type of operation, decrease the pressure and/or bring it to

zero in the gas and DHW circuits.

If the appliance is connected to a low temperature direct zone, it is necessary to check the necessary flow rate and possibly add a

relaunch pump.

Packing materials (staples, nails, plastic bags, polystyrene foam, etc.) constitute a hazard and must be kept out of the reach of

children.

If the appliance is installed inside or between cabinets, ensure sufficient space for routine servicing; for minimum installation

distances, see Fig. 3.

Before installing the appliance, ensure that it is delivered in perfect condition; if in doubt, contact the supplier immediately.

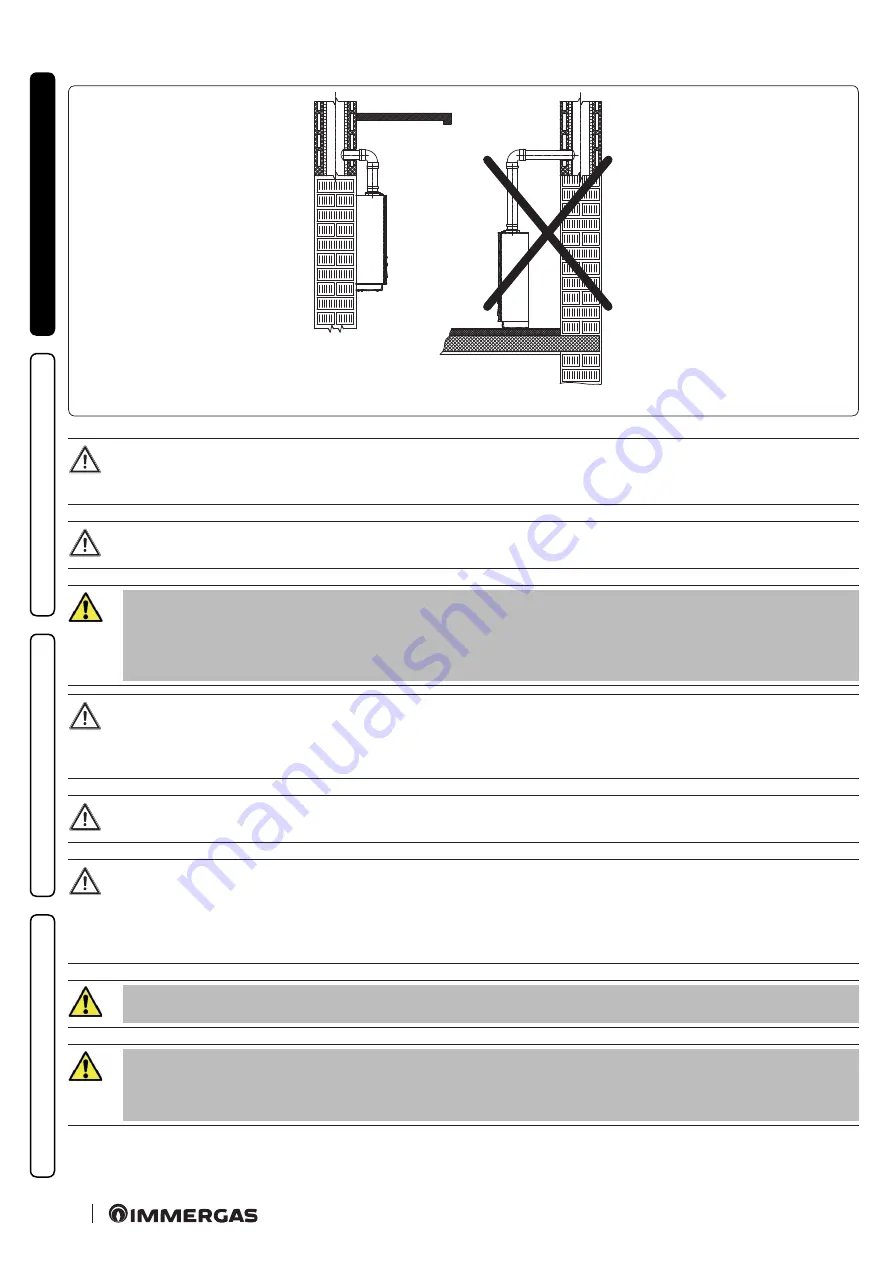

It is just as important that the intake grids and exhaust terminals are not obstructed.

Check that no flue gas recirculation is found in the air sample points. Allow the appliance to

reach the maximum heat output; theCO

2

value measured in the air must be less than 10% of

that measured on the flue gas.