29

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

3.17 YEARLY APPLIANCE CHECK AND

MAINTENANCE.

The following checks and maintenance should

be performed at least once a year.

- Clean the flue side of the heat exchanger.

- Clean the main burner.

- Visually check the flue hood for deterioration

or corrosion.

- Check correct lighting and operation.

- Ensure correct calibration of the burner in

domestic water

(when the boiler is connected

to an external cylinder)

and heating phases.

- Check correct operation of control and

adjustment devices and in particular:

- intervention of main electrical switch

positioned outside of the boiler;

- system control thermostat intervention;

- domestic hot water control thermostat

intervention

(when the boiler is connected to

an external cylinder)

.

- Check sealing efficiency of gas circuit and the

internal system.

- Check the intervention of the device against no

gas ionisation flame control. Intervention time

must be less than 10 seconds.

- Visually check for water leaks or oxidation

from/on connections.

- Visually check that the water safety drain valve

is not blocked.

- Check that, after discharging system pressure

and bringing it to zero (read on boiler

manometer), the expansion vessel charge is at

1.0 bar.

- Check that the system static pressure (with

system cold and after refilling the system by

means of the filling valve) is between 1 and 1.2

bar.

- Check visually that the safety and control

devices have not been tampered with and/or

shorted, in particular:

- temperature safety thermostat;

- water pressure switch,

- air pressure switch

- Check the condition and integrity of the

electrical system and in particular:

- electrical power cables must be inside the

fairleads;

- there must be no traces of blackening or

burning.

N.B.:

when performing periodical maintenance

of the appliance it is appropriate also to check and

perform maintenance on the heating system, in

compliance with that indicated by the regulations

in force.

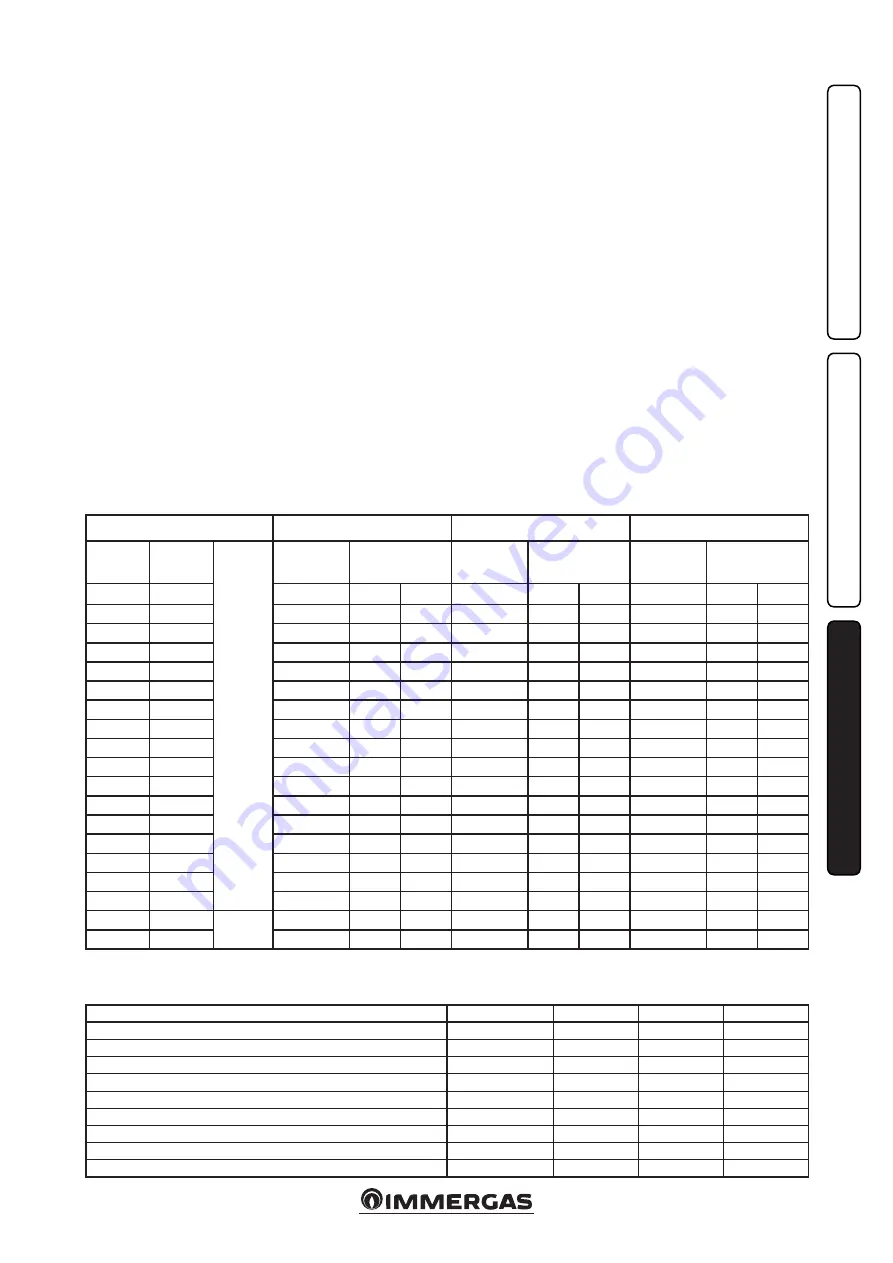

3.18 VARIABLE HEAT OUTPUT.

Attention:

based on the boiler model (checking

which type of fan is installed), use appropriate

data.

N.B.:

the pressures indicated in the table

represent the difference in existing pressures

between the gas valve outlet and the combustion

chamber. The adjustments should therefore,be

carried out using a differential manometer

(small "U"-shaped column or digital manometer)

with the probes inserted in the pressure test gas

valve outlet and on the sealed chamber positive

pressure test. The power data in the table has been

obtained with intake-exhaust pipe measuring 0.5

m in length. Gas flow rates refer to heating power

below a temperature of 15°C and at a pressure of

1013 mbar. Burner pressure values refer to use

of gas at 15°C.

3.19 COMBUSTION PARAMETERS.

FAN POWER: 30W

METHANE (G20)

BUTANE (G30)

PROPANE (G31)

HEAT

THERMAL

HEAT

THERMAL

CH

+

D.H.W.

GAS FLOW

RATE

BURNER

PRESS. NOZZLE

BURNER

GAS FLOW

RATE

BURNER

PRESS. NOZZLE

BURNER

GAS FLOW

RATE

BURNER

PRESS. NOZZLE

BURNER

(kW)

(kcal/h)

(m

3

/h)

(mbar) (mm H

2

O)

(kg/h)

(mbar) (mm H

2

O)

(kg/h)

(mbar) (mm H

2

O)

24.0

20640

2.71

11.19

114.1

2.03

27.77

283.2

1.99

35.95

366.6

23.0

19780

2.60

10.39

106.0

1.94

25.32

258.2

1.91

33.35

340.1

22.5

19353

2.55

10.00

102.0

1.90

24.15

246.3

1.87

32.10

327.4

21.0

18060

2.39

8.88

90.6

1.78

20.82

212.3

1.75

28.47

290.3

20.0

17200

2.28

8.17

83.3

1.70

18.76

191.3

1.67

26.18

267.0

19.0

16340

2.17

7.48

76.3

1.62

16.82

171.6

1.59

23.98

244.6

18.0

15480

2.06

6.83

69.6

1.54

15.01

153.1

1.52

21.88

223.1

17.0

14620

1.96

6.20

63.2

1.46

13.32

135.8

1.44

19.86

202.5

16.0

13760

1.85

5.59

57.0

1.38

11.74

119.7

1.36

17.93

182.8

15.0

12900

1.74

5.01

51.1

1.30

10.29

104.9

1.28

16.09

164.1

14.0

12040

1.63

4.46

45.5

1.22

8.94

91.2

1.20

14.33

146.1

13.0

11180

1.52

3.93

40.1

1.14

7.72

78.7

1.12

12.66

129.1

12.0

10320

1.41

3.42

34.9

1.06

6.62

67.5

1.04

11.07

112.9

11.0

9460

1.30

2.94

30.0

0.97

5.63

57.4

0.96

9.57

97.6

10.0

8600

1.19

2.49

25.4

0.89

4.76

48.6

0.88

8.15

83.1

9.3

7998

1.11

2.18

22.3

0.83

4.23

43.1

0.82

7.20

73.4

8.0

6880

D.H.W.

0.97

1.65

16.8

0.72

3.40

34.7

0.71

5.56

56.7

7.2

6192

0.88

1.34

13.7

0.65

3.00

30.6

0.64

4.63

47.2

G20

G30

G31

Gas nozzle diameter

mm

1.35

0.79

0.79

Supply pressure

mbar (mm H

2

O)

20 (204)

29 (296)

37 (377)

Flue flow rate at nominal heat output

kg/h

59

53

54

Flue flow rate at min heat output

kg/h

61

59

52

CO

2

at Nom Q./Min.

%

6.20 / 1.80

8.00 / 2.20

7.85 / 2.45

CO with 0% O

2

at Nom Q /Min.

ppm

74 / 138

135 / 152

93 / 123

NO

X

with 0% O

2

at Nom Q /Min.

mg/kWh

95 / 67

127 / 76

115 / 67

Flue temperature at nominal output

°C

96

106

105

Flue temperature at minimum output

°C

86

94

96

FAN POWER: 30W

Summary of Contents for MINI NIKE X 24 3 E

Page 1: ...MINI EOLO X 24 3 E Instruction and recommendation booklet IE 1 038775ENG ...

Page 2: ......

Page 28: ...28 3 5 4 4 5 6 6 d d c INSTALLER USER MAINTENANCE TECHNICIAN ...

Page 33: ......

Page 34: ......

Page 35: ......