25

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

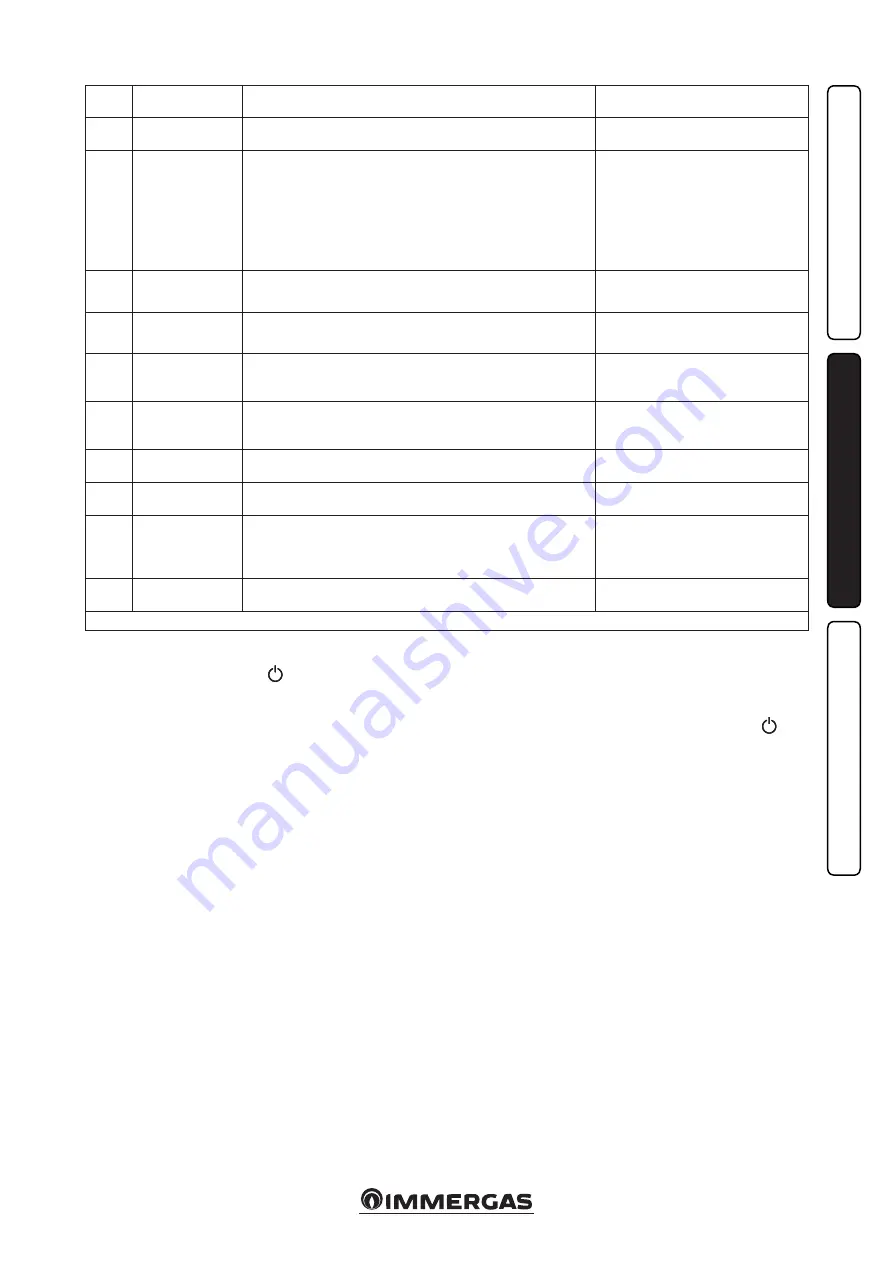

Error

Code

Anomaly signalled

Cause

Boiler status / Solution

29

Flue probe anomaly

If the board detects an anomaly on the flue gas probe the boiler will not

start

(1)

31

Loss of remote

control communi-

cation

This occurs if an incompatible remote control is connected, or if com-

munication between the boiler and the remote control is lost.

Power cycle the boiler. If the Remote Con-

trol is still not detected on re-starting the

boiler will switch to local operating mode,

i.e. using the controls on the control panel.

In this case function “CH ON” cannot be

activated. To make the boiler work in “CH

ON” mode, activate the “P33” function

present inside the “M3” menu (1).

32

Low tempera-

ture zone 2 probe

anomaly

If the board detects an anomaly on the low temperature zone 2 probe, the

boiler cannot work in the affected area.

(1)

33

Low tempera-

ture zone 3 probe

anomaly

If the board detects an anomaly on the low temperature zone 3 probe, the

boiler cannot work in the affected area.

(1)

34

Low temperature

zone 2 safety ther-

mostat intervention

During operation, if a fault causes excessive over-heating internally on

the low temperature zone 2, the boiler does not satisfy the requests of

the interested zone.

If normal conditions are restored the boiler

restarts without needing to be reset (1).

35

Low temperature

zone 3 safety ther-

mostat intervention

During operation, if a fault causes excessive over-heating internally on

the low temperature zone 3, the boiler does not satisfy the requests of

the interested zone.

If normal conditions are restored the boiler

restarts without needing to be reset (1).

36

IMG Bus communi-

cation loss

Communication between the control units is interrupted due to an

anomaly on the boiler control unit or on the IMG Bus.

The boiler does not satisfy the room heating

requests (1).

37

Low power supply

voltage

This occurs when the power supply voltage is lower than the allowed limits

for the correct boiler operation.

If normal conditions are restored the boiler

restarts without having to be reset (1).

38

Loss of flame signal

This occurs when the boiler is ignited correctly and the burner flame

switches off unexpectedly; a new ignition attempt is performed and if

normal conditions are restored, the boiler does not need to be reset (this

fault can be checked in the list of errors in the “M1” menu only).

If normal conditions are restored the boiler

restarts without having to be reset (1).

47

Burner power

limitation

Should flue high temperature be detected, the boiler reduces power sup-

plied so as not to damage it.

(1).

(1) If the shutdown or fault persists, contact an authorised firm (e.g. Authorised Technical After-Sales Service).

2.7 BOILER SHUTDOWN

Switch the boiler off by pressing the “

” but-

ton, disconnect the onmipolar switch outside of

the boiler and close the gas cock upstream of the

appliance. Never leave the boiler switched on if

left unused for prolonged periods.

2.8 RESTORE CENTRAL HEATING

SYSTEM PRESSURE.

Periodically check the system water pressure.

The boiler pressure gauge should read a pressure

between 1 and 1.2 bar.

If the pressure falls below 1 bar (when the circuit is

cold) restore normal pressure via the relevant cock

located to the right of the boiler and accessible from

the side door (Fig. 2-8).

N.B.:

close the cock after the operation.

If pressure values reach around 3 bar the safety

valve may be activated.

In this case, remove water from an air vent valve

of a radiator until reaching pressure of 1 bar, or

ask for assistance from professionally qualified

personnel.

In the event of frequent pressure drops, contact

qualified staff for assistance to eliminate the pos-

sible system leakage.

2.9 SYSTEM DRAINING.

To drain the boiler, use the special draining valve

(Fig. 1-27).

Before draining, ensure that the filling cock is

closed.

2.10 CYLINDER DRAINING.

To drain the storage tank, use the special draining

valve (Fig. 1-27).

N.B.:

before performing this operation, close

the boiler cold water inlet valve and open any

DHW system hot water valve in order to air

into the cylinder.

2.11 ANTIFREEZE PROTECTION.

The boiler comes standard with an antifreeze

function that activates the pump and burner

when the system water temperature in the boiler

falls below 4°C.

The antifreeze function is only guaranteed if:

- the boiler is correctly connected to gas and elec-

tricity power supply circuits;

- the boiler is powered constantly;

- the boiler is on and not in stand-by (

)

- the boiler is not in no ignition block (Par.

- the boiler essential components are not faulty.

In the case of prolonged inactivity (second

home), we also recommend to:

- disconnect the electric power supply;

- fully drain the central heating circuit, the boiler

domestic hot water circuit and the condensa-

tion trap. In systems that are drained frequently,

filling must be carried out with suitably treated

water to eliminate hardness that can cause lime-

scale.