General Troubleshooting

For system specific troubleshooting see the table at the end of each system

assembly instructions.

Problem

Solution

triflex

®

R comes out of the end of arm bracket

1. Check to make sure Lock Clips are being

used

2. Check to make sure that triflex

®

R is run in

the correct direction with the ball end run in

the direction of the tool

3. Ensure that the bend radius of the triflex

®

R is not being violated during the robot

motion. To relieve this condition, adjust the

end of arm bracket and axis 6 clamp

Cable breaks in the area of the end arm tool

1. Make sure strain relief has been properely

installed at the end of arm bracket

2. Confirm that the service loop from the end

of arm bracket to the tool connection is

sufficient

3. Confirm that a torsion rated cable is being

used. If not, contact igus

Cable is coming out of the split opening of triflex

®

R TRE

1. Make sure strain relief hs been properely

installed at the end of arm bracket

2. Confirm that the chamber inside triflex

®

R is

not overloaded

3. Ensure that the cables entering the fixed

end of the system at axis 3 are not pulled

too tight

triflex

®

R TRE is getting caught on the robot and

is damaged

1. Install a triflex

®

R protector in any location

that makes contact with the robot arm.

These should be installed 3-5 links apart

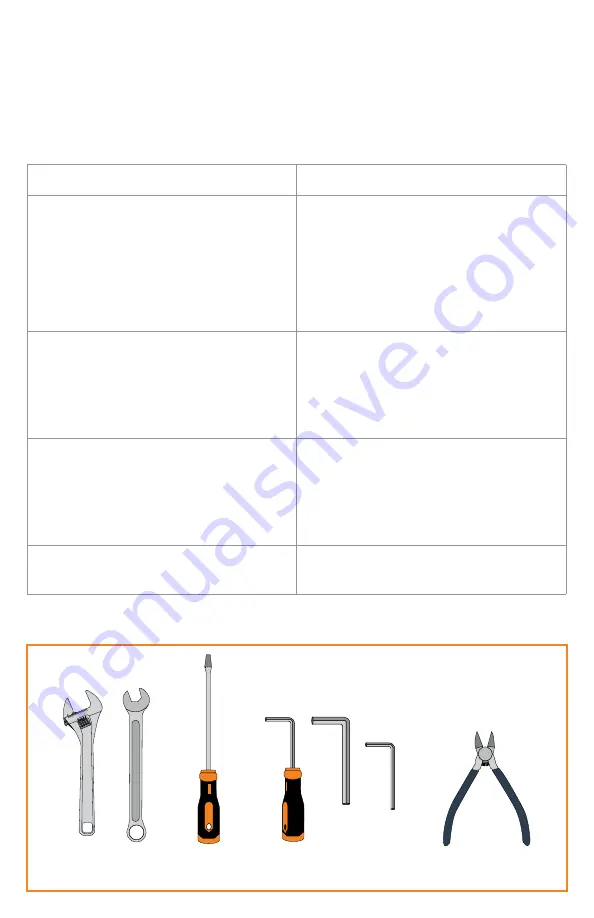

wire cutter

allen keys

screwdriver

wrenches

Tools needed for installation:

Summary of Contents for triflex R

Page 2: ...inside cover blank RSP shown...

Page 13: ...13 triflex RSE linear Installation examples...

Page 21: ...21 triflex RSE Wheel Installation examples...

Page 25: ...25 triflex RS Installation examples...

Page 33: ...33 triflex RSP Installation examples...

Page 34: ...34 Notes Assembly guide notes...

Page 35: ...35 Notes Assembly guide notes...