42

HYDRAULIC CONNECTION

SPECIFICATIONS

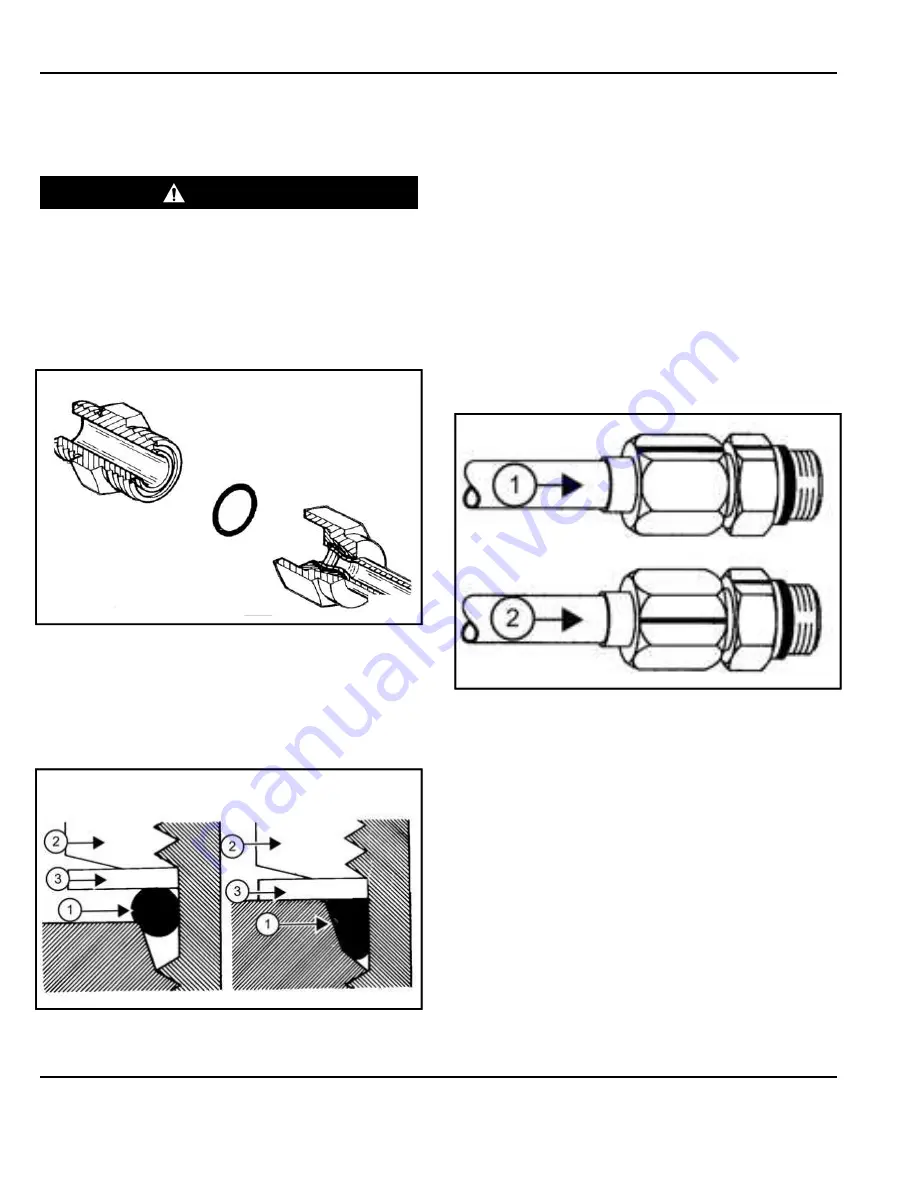

O-ring Face Seal Connection

IMPORTANT

MACHINE DAMAGE

When repairing hydrostatic and hydraulic systems,

clean the work area before disassembly and keep all

parts clean.

Always use caps and plugs on hoses, tubelines, and

ports to keep dirt out. Dirt can quickly damage the

system

◂

I-2003

Figure 61

B-7575

Use petroleum jelly to hold the O-ring in position until the

fittings are assembled. To eliminate leakage do not under

or over tighten [Figure 61].

Straight Thread O-ring Fitting

Figure 62

A1852a

Lubricate the O-ring (Item 1) before installing the fitting.

Loosen the nut (Item 2) and install the fitting. Loosen the

nut and install the fitting. Tighten the nut until the washer

(Item 3) [Figure 62] is tight against the surface.

Tubelines And Hoses

Replace any tubelines that are bent or flattened. They will

restrict flow, which will slow hydraulic action and cause

heat.

Replace hoses which show signs of wear, damage or

weather cracked rubber.

Always use two wrenches when loosening and tightening

hose or tubeline fittings.

Tightening The Flare Fitting

Figure 63

TS1619b

Tighten the nut until it makes contact with the seat. Make

a mark across the flats of both the male and female parts

of the connection (Item 1) [Figure 63].

Use the chart below to find the correct tightness needed

(Item 2) [Figure 63]. If the fitting leaks after tightening,

disconnect it and inspect the seat area for damage.

Summary of Contents for Auger 75 DDH

Page 2: ......

Page 12: ...10 Figure 4 C221899a SAFETY AND TRAINING RESOURCES ...

Page 29: ......

Page 52: ...50 troubleshooting 29 W warranty 48 welding safety 7 ALPHABETICAL INDEX ...

Page 53: ......