www.igmtools.com

3

Operating manual

EN

- EN 2 -

11,55

mm

S

workpiece Y

wor

kpiec

e X

wor

kpiec

e Y

Set up

- Attach edge guides to the jig in the positions listed in the table above.

- Place X workpiece into front clamp bar. Tighten front clamp knobs.

- Place Y workpiece into top clamp bar.

- Push Y workpiece tightly against the edge guide and workpiece X. Tighten top

clamp knobs.

- Retighten X workpiece, so that the top of front X workpiece is flush with the top of

workpiece Y and snugly against edge guide.

- Tighten front clamp knobs .

until 2014

- Adjust template position to align the setting line with the edge of the workpiece

under the top clamp.

until 2015

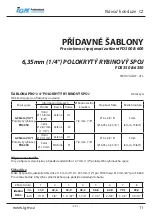

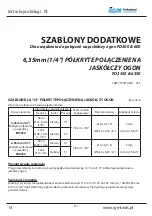

- On the workpiece Y, draw a line at a distance of 11,55 mm from the edge of this

workpiece Y (see figure). Adjust the template position to align this line with the

tops of the dovetail grooves.

- One rotation of template adjustment nut stop equals 1 mm.

- Tighten template assembly knobs.

- Attach the template guide to the router base.

- Install the dovetail bit in the router.

- Adjust the cutting depth of the dovetail bit according to table.

Note

: Recommended bit depths are approximate only, always make test cuts in scrap stock to determine the

exact depth for your application!

Routing

- Place the router on the template ensuring that the router bit does not touch the workpiece.

- Switch on. Make one very light cut from left to right cutting only the front edge. This prevents the breakout.

- Rout carefully from left to right following the fingers of the template with the template guide.

- Switch off the router and carefully remove from jig.

- Check that all slots are routed clean. If not, rout again.

- Remove the workpiece from the jig.

- Test joint.

ATTENTION !

Do not lift the router from the template as damage to the template and router bit will occur.

If the joint is not perfect :

Joint too loose= increase cutting depth of router bit.

Joint too tight= decrease cutting depth of router bit.

Joint too shallow= move template towards the jig body.

Joint too deep= move template away from the jig body.

Summary of Contents for FD3350

Page 23: ...www igmtools com 23...