16

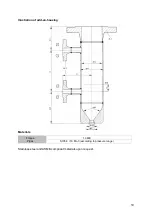

5.4 Fitting the electrode

It is essential to remove the protective tube for transport before

installation!

If several electrodes are screwed into a flange the probe plugs (2) and the

associated probes should be labelled to prevent confusion!

EL968 and MS015A/B: check separate Installation and Operating instruction

Fixing the electrode extension (9)

Push the electrode extension (9) approx.

30 mm over the electrode shank (8) until

the ø 4.3 mm hole matches the threaded

hole in the electrode shank.

Screw up both parts by means of the

enclosed M4 set screw with AF2 hexagon

socket.

Screwing in the electrode

•

Release screw (1) and pull off electrode plug (2)

•

Clean and check sealing surfaces

•

Insert (new) sealing ring (6)

•

Lubricate thread (7) with heat-resistant solid lubricant

(e.g. graphite).

•

Screw in electrode and tighten, max. tightening

torque Md=140 Nm.

•

Make electrical connection only after installation in

the boiler.

Do not seal thread with PTFE strip or

the like!

When commissioning the boiler, check

the probe screw connection in the

flange for leaks and retighten if

necessary!

Screw

probe plug

Seal

Contact carrier

Threaded ring

Sealing ring

Thread

Electrode shank

Electrode

extension

Danger

Danger

Danger

Caution

Summary of Contents for SMLC2

Page 26: ...26 10 Conformity declaration...

Page 27: ...27 11 Certificates PED Type Examination...

Page 28: ...28 SIL 3 Zertifizierung...

Page 30: ...30...

Page 31: ...31...