6

4.2 Sources of interference in the pipe system

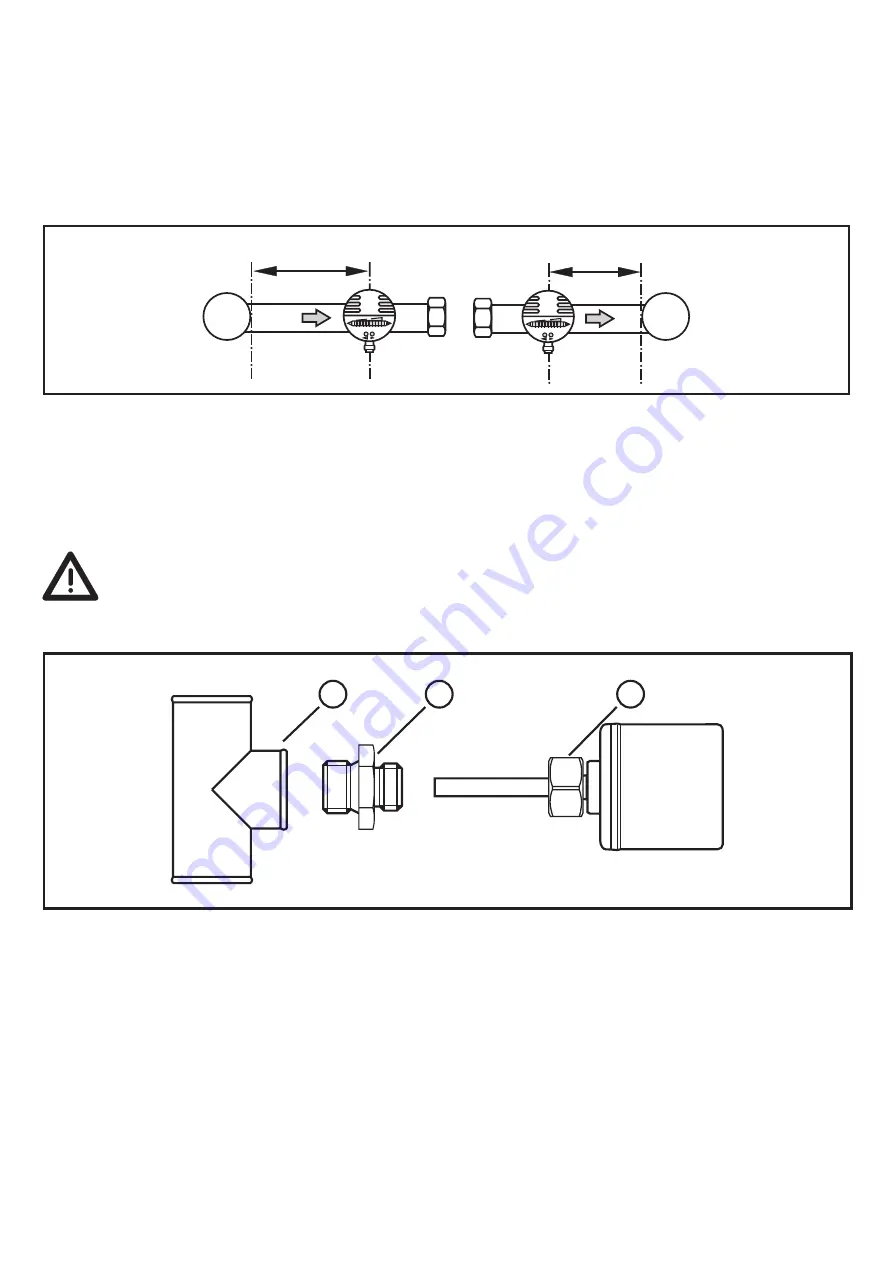

Components integrated in the pipes, bends, valves, reductions, etc� lead to turbu-

lence of the medium� This affects the function of the unit�

Recommendation: Adhere to the distances between sensor and sources of inter-

ference:

D = pipe diameter; S = sources of interference

Open outlets, tubes not completely filled / emptied are to be avoided due to the

high measuring sensitivity of the units�

4.3 Mounting operation

► Ensure that the system is free of pressure during installation�

► Ensure that no media can leak at the mounting location during installa-

tion�

► Grease the threads of the process connection (1), adapter (2) and nut (3)�

Note: The sensor tip (A) must not be in contact with grease�

► Screw the suitable adapter into the process connection�

► Place the flow monitor onto the adapter and tighten the nut� Tightening torque

25 Nm� Ensure that the unit is correctly oriented�