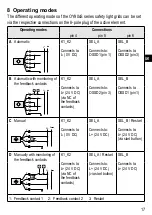

20

9.1 LED indicators for optical alignment

The indication LEDs of the safety light grid help to correctly align the active and

the passive element with each other�

9.1.1 Alignment in the automatic mode

Description

Active element

LED

orange

red

green

yellow

Element does not detect any light beam

Element detects all light beams with a weak

signal

Element detects all light beams

►

Align the active element so that the green LED lights�

►

Securely fasten the active and the passive element�

9.1.2 Alignment in the manual mode

In the manual operating mode the yellow LED lights instead of the green one� The

light grid will then wait for the manual release�

Description

Active element

LED

orange

red

green

yellow

Element does not detect any light beam

Element detects all light beams with a weak

signal

Element detects all light beams

►

Align the active element so that the yellow LED lights�

►

Securely fasten the active and the passive element�