GB

6 - USE AND OPERATION

MASTER 880MP E-volution

6 - Pag. 10 / 17

6.5.1

BAR STRAIGTHNESS - Measuration

The bar vibrations are partially caused by the condition of the bar itself: in case the bar is not

perfectly straight, this can cause vibrations.

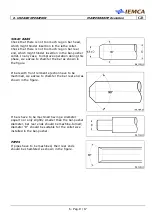

Round bars

As stated also in the UNI-10233/2 regulation, the

bar straightness can be measured by positioning

the bar on two V-supports and control its

straightness. In that case, the measurement can

be carried out as shown in the figure.

It is necessary to rotate the bar on itself and

measure the three indicated sections. In this

case the S-max value (difference between

maximum and minimum reading on the comparator) should be interpreted as follows:

S max

Quality

< 0,25 mm

Good

0,25 < S max < 0,5 mm

Mediocre

> 0,5 mm

Problematic

In order to obtain a reliable value it is necessary to repeat measurements on the whole bar

length by positioning it on a series of supports at a distance of 500 mm from each other and

comparing the different values between prisms.

INFORMATION:

Obviously, bar straightness is proportional to the rigidity of the material and to

the number of revolutions (RPM) the lathe is operated at. highly The lack of bar

straightness highly influences the maximum number of revolutions reachable:

the bigger the diameter the greater the influence. The data concerning bar

straightness do not absolutely refer to local inflection and/or deformation that

the bar shall not absolutely show. Instead, they refer to the bar uniform

curvature.

INFORMATION:

For efficient operation of the feeder the use of rolled bar stock is not

recommended.

Summary of Contents for MASTER 880 MP-E

Page 2: ......

Page 4: ......

Page 6: ......

Page 95: ...10 LIST OF AFTER SALES CENTERS GB 10 Pag 1 3 INDEX 10 1 LIST OF AFTER SALES CENTERS 2 ...