2 - TECHNICAL INFORMATION

MASTER 880MP E-volution

GB

2 - Pag. 15 / 19

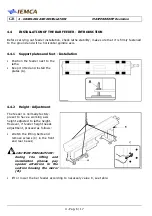

Table 5. Working axis height

Model

Screws position

X (mm)

High bedframe

X (mm)

Low bedframe

2

1215÷1249

900÷934

3

1250÷1284

935÷969

4

1285÷1319

970÷1004

5

1320÷1354

1005÷1039

6

1355÷1389

1040÷1074

7

1390÷1424

1075÷1109

8

1425÷1459

1110÷1144

9

1460÷1494

1145÷1179

MASTER 880 P

MASTER 880 F

10

1495÷1535

1180÷1220

Summary of Contents for MASTER 880 MP-E

Page 2: ......

Page 4: ......

Page 6: ......

Page 95: ...10 LIST OF AFTER SALES CENTERS GB 10 Pag 1 3 INDEX 10 1 LIST OF AFTER SALES CENTERS 2 ...