B-1908-1(0)

INSTRUCTION SHEET - HS1L Series

Solenoid Type Safety Switch, Inside Connector type

( 3 / 6 )

2016.08

(Type HS1L-

□

4)

The HS1L allows manual unlocking of the key to precheck door operation before wiring

or turning on power, as well as for emergency use such as a power failure.

(Type HS1L-

□

7Y)

In case the actuator is not unlocked when the solenoid is deenergized, the actuator

can be unlocked manually.

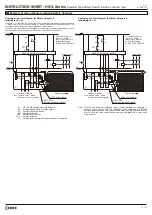

For Manual Unlocking

• HS1L with manual unlock key

:

To change the normal position to the

manual unlocking position as shown on the

right, turn the key fully (90 degrees) using

the red plastic key included with the safety

switch.

Using the safety switch with the key being

not fully turned (less than 90 degrees) may

cause damage to the safety switch or errors.

(note: when manually unlocked, the safety switch will keep the main circuit and the

lock monitor circuit disconnected and he door unlocked.)

Do not attach the key to the safety switch intentionally (the key is designed to fall off

when he operator's hand is off the key).

In such case, safety standards become unapplied because the

safety switch can be always unlocked during machine opera-

tion, and therefore will give hazardous conditions to workers.

• HS1L without manual unlock key

Remove the screw at the side of the safety switch using the

wrench for mounting the HS1L lid. Push the lever inside the

safety switch toward the pilot light using a small screwdriver

until the actuator is unlocked. See the figure on he right.

•

Common

Insert a small screwdriver form the hole of the reverse side of

the safety switch. Push the pin inside the safety switch toward

the pilot light using a small screwdriver until the actuator is

unlocked.See the figure on the right.

A hole for the lever should be opened on the mounting panel.

When opening the hole, apply proper protection against water

and other foreign objects.

(Unlocking Method)

Manual

Unlocking

Position

Normal

Position

UNLOCK

UNLOCK

4

Precautions for Operation

Installation

• Do not apply an excessive shock to the safety switch when opening or closing the

door. A shock to the safety switch exceeding 1,000 m/s

2

may cause failure.

• Provide a door guide, and ensure that force is applied on the safety switch only in

the actuator insertion direction.

• Do not pull the actuator while it is locked. Also, regardless of

door types, do not use the safety switch as a door lock. Install

a separated lock as shown in item 3.

• When opening the safety switch lid to wire, open the lid

only. (See the figure on the right.) Never remove other screws,

otherwise the safety switch may be damaged.

• The safety switch cover can be only removed or installed with

the special L-shaped wrench supplied with the safety switch.

• Entry of foreign objects in the actuator entry slot may affect the

mechanism of the safety switch and cause a breakdown. If the

operating atmosphere is contaminated, use a protective cover

to prevent the entry of foreign objects into the safety switch

through the actuator entry slots.

• Avoid foreign objects such as dust, liquid and oil from entering

the safety switch while connecting a conduit or iring.

• Make sure to install the product in a place where it cannot be

damaged. Make sure to conduct a proper risk assessment

evaluation before using the product, and use a shield or a cover to protect the prod-

uct if need be.

• While the solenoid is energized , the switch temperature rises

approximately 40°C above the ambient temperature (to approximate-

ly

95 °C

while the ambient temperature is 55°C). Keep hands off to

prevent burns.

• Use only the designated actuator for the HS1L. Other actuators will cause a break-

down of the safety switch.

• Solenoid / Indicator has polarity. Besure to wire correctly.

• Fully press down on the lock nut of the safety switch so they are not lifting or rattling

when tightening the connector. Tighten it carefully so that there is no gap between

the connector and safety switch.

A

L-shaped wrench

attached to the

safety switch

Type : HS9Z-T1

A

A

• To ensure safety, make sure that the power is

turned off before opening or closing the cover.

• Do not touch the part B (shown in the figure on the

bellow) with tools or fingers when opening the

interlock switch cover. Otherwise the interlock

switch may be damaged.

• Close the cover only as described below, otherwise

failure of interlock switch will be caused.

(Method)

1. Confirm that the manual unlock state on the

cover is in "normal state".

2. Open the door (actuator is removed).

3. Close the cover, and tighten the screws to the

appropriate torque.

Opening / Closing the Cover (Type : HS1L-*K)

normal

state

UNLOCK

2.Open the door

(

actuator is removed

)

B

1.

WARNING

• Turn off the power to the safety switch before starting installation, removal, wiring,

maintenance, and inspection on the safety switch. Failure to turn power off may

cause electrical shocks or fire hazard.

• Do not disassemble or modify the switch. Also do not attempt to disable the

interlock switch function, otherwise a breakdown or an accident will result.

• Use wires of a proper size to meet voltage and current requirements.

Screwdriver

CAUTION

• Before manually unlocking the safety switch, make sure the machine has come to

a complete stop. Manual unlocking during operation may unlock the safety switch

before he machine stops, and the function of safety switch is lost.

• While the solenoid is energized, do not unlock the actuator manually (Solenoid

lock type).

CAUTION

• HS1L Series Safety Switches are Type 2 low-level coded interlocking devices (EN

ISO / ISO14119). The following system installation & mounting instructions are EN

ISO / ISO14119 requirements to prevent function failure from the interlock switch.

1. Using permanent fixing methods (e.g. welding, rivets, special screws...etc) to

prevent dismantling or de-positioning of the interlock device. However, perma-

nent fixing methods are not an adequate solution if you expect the interlock

device to fail during the machinery lifetime, or if you need to replace the prod-

uct in quick manner. In these situations, other measures (see 2.) should be put

in place to reduce the risks of function failure.

2. At least one of the following measures should be applied to prevent function

failure.

(1) Mounting the interlock device in a place out of reach from workers

(2) Using shielding protection to prevent physical obstruction of the device

(3) Mounting the interlock device in a hidden position

(4) Integrate status monitoring & cycling testing of the device to the control

system to prevent product failure.

• Do not instal the actuator in the location where the human body may come into

contact. Otherewise injury may occur.

• Pay attention to the management of spare actuator. Safety function of safety

switch will be lost in case the spare actuator is inserted into the safety switch.

Ensure that the actuator is firmly fastened to the door (welding, rivet, special

screw) in the appropriate location, so that the actuator cannot be removed easily.

• Do not cut or remodel the actuator, otherwise failure will occur.

ur t a

t

rm fa

o

cial

s r ) in the p o ri

oca on o th t e actu to can

d easily

• Performance Level according to EN ISO 13849-1 is reduced with series connected

safety components due to decreased fault recognition.

• The insulation of the cable has to wi hstand environmental influences.

• The overall concept of control system, into which the safety components has been

integrated, must be validated in accordance with EN ISO 13849-2.