29

Three-position Enabling Switches/Grip Style Three-position Enabling Switches

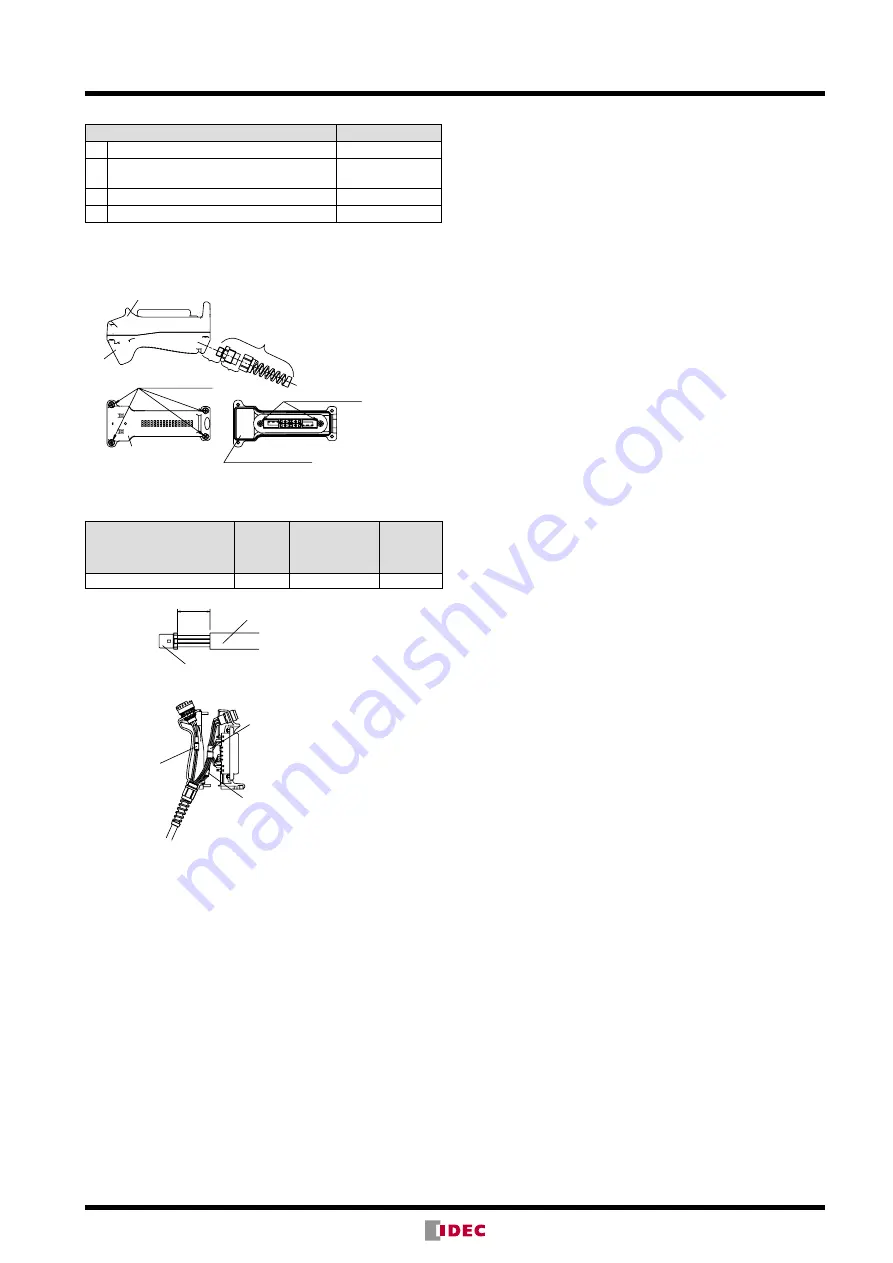

Recommended Tightening Torque

Parts for tightening

Torque

A Base and rubber kit (M4 screw × 4)

1.1 to 1.3 N·m

B Cable gland and grip style enabling

switch

2.7 to 3.3 N·m

C Cable gland

2.7 to 3.3 N·m

D HE2B Enabling Switch (M3 screws × 2)

*

0.5 to 0.8 N·m

Note: The recommended tightening torques of B and C are for

the supplied cable gland. When using another cable gland,

refer to the tightening torque of the cable gland used.

*

For replacing HE2B enabling switch or rubber boot only

Rubber Boot Kit

Cable Gland

Base

Base

B

C

D (M3 scew × 2)

A (M4 scew × 4)

Rubber Boot Kit

HE2G (internal connector)

Wire Length inside the Switch

Grip

Style

Enabling

Switch

Momentary

Pushbutton/Key

Selector Switch

Emergency

Stop

Switch

Wire stripping length L1 (mm)

20

60

75

Cable gland for

emergency stop switch

Cable gland for

momentary pushbutton/

key selecetor switch

Cable gland for

grip style enabling switch

L1

Sheath

<Example>

Applicable cable gland

on cable side

• Applicable wire size for the cable gland on cable side

• 0.05 to 0.86mm

2

(AWG18 to 30): Check the compliance with

receptacle and contact.

Tool: 1762846-1 (manual tool)

Note: When using stranded sires, make sure that loose wires do

not cause short circuit. Also, do not older the terminals

to prevent loose wires. Use copper wire of 60°C or 75°C

temperature rating in order to comply with UL508. Observe

the requirements of GS-ET-22: 2003, 4.2.6 for wiring.

Operating Instructions

HE2B/HE3B/HE5B/HE6B/HE1G/HE1G-L/HE2G

• To achieve a high level of safety, connect the two contacts of the

3-position switch to a disparity detection circuit (e.g., safety relay

module) (ISO 13849-1, EN 954-1).

• Because two contacts are designed to operate independently,

pressing the edge of a button turns on one contact earlier than

the other contact, causing a delay in operation. To avoid this,

always press the center of the button.

HE1B/HE2B/HE3B/HE5B/HE6B/HE1G/HE1G-L/HE2G

• 3-position enabling switches output ON signals in position 2.

Sys tems must be designed to enable machine operation when

the 3-position enabling switch is in position 2 only.

• Perform a risk assessment in actual applications as strong force

may be applied to the switch when depressed to position 3.

• Perform a risk assessment for the shape and structure of the

part where the enabling switch is installed, to prevent unintended

operation of the enabling switch. For example, an enabling

switch protruding from the teach pendant may result in an unin-

tended operation of the enabling switch.

• Strong force may be applied to a 3-position enabling switch

when pressed to position 3. Provide sufficient strength to the

part where 3-position enabling switches will be installed.