6

EVOMAX - Low Height Frame & Header Kits

3.1 GENERAL

•

Frames: These are provided in a single frame format and are

designed to be bolted side by side up to a maximum of three

frames and must be bolted together using the bolts provide.

•

Water header with built in gas header cradles and mounting

brackets that allow its connection to the frames can be

obtained in DN50 single boiler format, DN 65 two boiler

format or a DN 80 three boiler format.

•

2” gas header with inlet test points

•

All the pumps, associated safety controls, pipes and

fittings required to connect the water and gas header to the

appliances are supplied.

3.2 MAIN WATER HEADERS

The main water header consists of un-insulated water flow and

return pipes incorporating location and frame mounting brackets

sized to cater for the Evomax range of products available for use

with these kits.

The Single unit water header is a DN 50 pipe system with

threaded connections. (Threaded flanges are provided with DN50

Evomax low height Low loss header kit).

The twin water header is a DN 65 pipe system with flanged

connections and is available with the DN65 Evomax low height

Low loss header kit.

The three unit system uses a DN 80 pipe system with flanged

connections and is available with the DN 80 Evomax low height

Low loss header kit.

3.3 GAS HEADER

The gas header consists of a 2” manifold tailored to fit the two

or three unit versions available and is located in the cradle

incorporated in the water header bracket structure.

All the pipe work and connections are provided to connect the

header to the required appliance.

Test points are provided at each end of the 2” gas header. The test

point nearest to the gas inlet is intended to be used as the appliance

inlet pressure point.

3.4 LOW LOSS HEADERS (MIXING HEADERS)

All variants of these kits must be fitted to suitably sized low loss header.

The Evomax low height low loss headers have been designed to

match the lower positioned water headers used in these kits. This has

required the drain point to be moved the lowest side point available.

Note; Bespoke low loss headers may not be able to connect directly

to these headers due to the change in pitch and position of the

header pipe work used in these kits. (See frame fit low loss header)

Ideal recommend:- DN 50 – 209394, DN 65 – 209395,

DN 80 - 252437.

3.5 BOILER SHUNT PUMP

The pumps supplied with these kits are design to provide the

optimum flow around the appliance water circuit ensuring the

maximum flow rates are contain within the design constrains of

the appliance.

It is not recommended to fit additional pumps directly to the

appliance circuit unless they have been designed to ensure the

maximum permissible appliance flow rate is not exceeded.

It is recommended that the appliance circuit pumps are set to

Constant Pressure setting.

Pumps supplied with these rigs are designed to be connected to

the relevant appliance electrical connections to ensure pump over

run capability is available to manage the appliances operation.

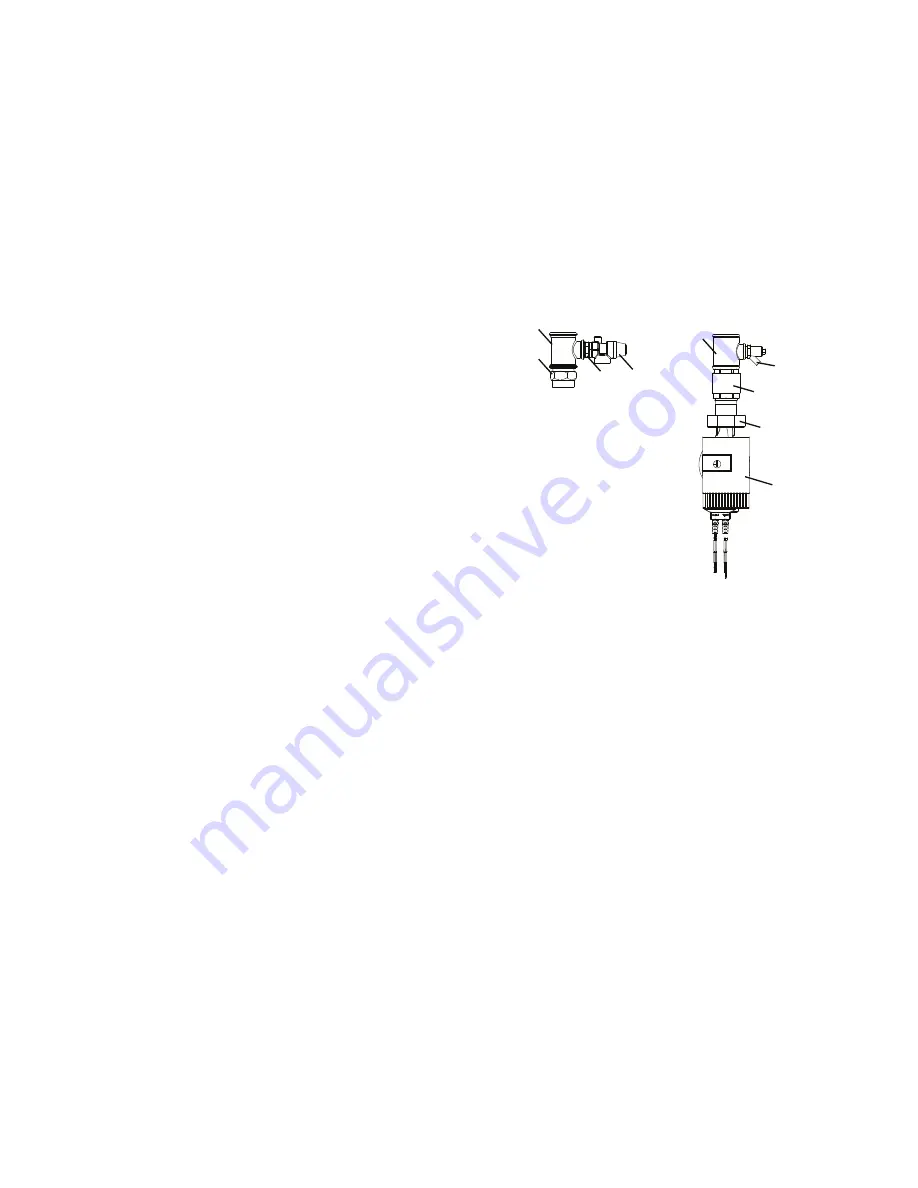

3.6 BOILER CONNECTION KITS

These boiler connections are un-insulated and contain the

following:

LEGEND

1. Tee 1

1

/

4

" X

3

/

4

" X 1

1

/

4

"

2. Brass union

3

/

4

" X

3

/

4

"

3. Safety relief valve 3 bar

4. 1

1

/

4

" X

1

/

2

" X 1

1

/

4

" Tee

5. Drain plug

6. Pump fitting

7. Non return valve

8. Pump inc. gaskets

9. 1

1

/

4

" taper male to 1

1

/

4

" parallel hex adapter

Note. For boiler connection assembly, refer to Frame 5.3

3.7 FREE-STANDING FRAMES

The low height frames are designed to provide a compact floor

mounted structure capable of having any of the Evomax range of

appliances fitted to them. Incorporating all the required mountings

and assembly systems to bolt up to three frames together in a

side by side format and mount the relevant water and gas heater

kits.

Provision is also provided to allow the frames to be bolted to the floor.

Note: Floor mounting bolts are NOT provided.

3.8 INSTALLATION AREA AND DIMENSIONS

Care must be taken to ensure adequate access for boiler /

cascade system installation and servicing.

A minimum of 450mm must be provided from the front of the

installed boilers to facilitate boiler servicing.

Consideration to connecting heating flow and return pipework,

gas supply and condensate drainage must be given. Routing

of the condensate drain must be made to allow a minimum fall

of 1 in 20 away from the installed boilers, throughout its length.

Adequate room above the boilers must be provided to install and

service the boiler flue system. Further information with respect

to flue and condensate drain connection is provided in the

installation and servicing instructions provided within the boilers

packaging carton.

3 SYSTEM COMPONENTS

3

2

1

9

FLOW

RETURN

4

5

6

7

8

Note

.

Isolating Valves

are fitted to water

header along with

flexible connecting

pipes.