3

Concord CXC -

Installation

CONTENTS

Air Supply. ........................................................................ 9

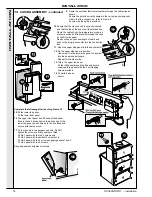

Boiler Assembly - exploded view. ............................... 10

Boiler Clearances. ........................................................... 6

Burner Assemblies - exploded views. .............................

CXC 48-70. ................................................................ 28

CXC 94-116. ............................................................... 29

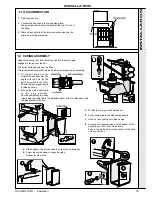

Casing Assembly. .......................................................... 13

Commissioning. ............................................................. 18

Condensate Drain Connection ..................................... 12

Controls. ........................................................................... 5

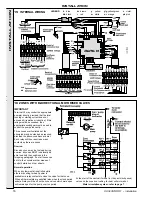

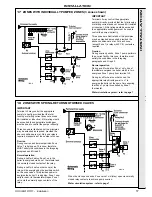

Electrical Connections. ................................................. 15

Electrical Supply. ........................................................... 10

Fault Finding. ................................................................. 33

Flue System. ..................................................................... 9

Gas Connections. .......................................................... 13

Gas Safety Regulations ................................................... 3

Gas Supply. ..................................................................... 10

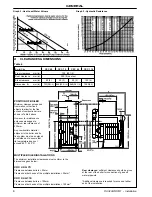

Hydraulic Resistance. ...................................................... 6

Initial Lighting. ................................................................ 18

Installation. ..................................................................... 10

Mandatory Requirements. ............................................... 9

Option Kits. ....................................................................... 5

Pump. ................................................................................ 7

Servicing. ........................................................................ 25

Short List of Parts. ......................................................... 36

Static Head Requirements. ............................................. 7

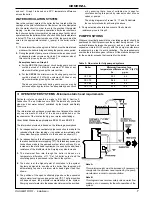

Ventilation. ........................................................................ 9

Water Circulation. ............................................................ 7

Water Connections. ......................................................... 5

Water Treatment. .............................................................. 8

Wiring Diagrams. ........................................................... 16

INTRODUCTION

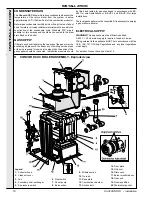

CONSTRUCTION

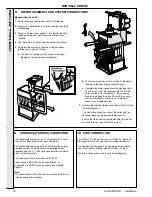

BOILER BODY

The Concord CXC boiler consists of 2 basic parts; a conventional

Concord CXD boiler; plus an additional heat exchanger.

The Concord CXC boiler body is constructed from cast iron

sections, insulated by a foil backed fibre glass blanket. It is mounted

on a sheet steel combustion chamber.

An aluminiumised mild steel flue collector hood and stainless steel

condensate sump is fitted on top of this heat exchanger. The sump

supports the secondary heat exchanger which is constructed from

aluminium finned tubes between aluminium and cast iron headers.

This heat exchanger is also insulated by a foil backed fibre glass

blanket.

Above the primary heat exchanger an induced draught fan is fitted

- capable of overcoming the resistance of a 30m length of 6" flue

pipe. The boiler is supplied with header pipework between the

primary and secondary heat exchanger.

Within this pipework, a 'shunt' pump is provided to ensure an

adequate flow through the primary heat exchanger, independently

of the system pump. This also ensures that a sufficient temperature

is maintained in the primary heat exchanger to prevent corrosion.

CASING

The combined boiler bodies are enclosed in a white, stove

enamelled casing which incorporates a control panel fascia.

The casing is specially designed to ensure easy access for both

servicing and cleaning of both heat exchangers.

BURNERS

The 3 burners are of stainless steel construction.

Gas Safety (Installation and Use) Regulations, 1994,

amendments 1996 or rules in force.

It is the law that all gas appliances are installed and serviced by a

CORGI registered installer (identified by

) in accordance with

the above regulations. Failure to install appliances correctly could

lead to prosecution. It is in your own interest, and that of safety, to

ensure that the law is complied with.

The Concord CXC 48/116 range of boilers has been tested and

certified by British Gas to prEN656 for use with

Natural gas only.

Note.

The CXC 48 and CXC 70 boilers are intended for use as

COMMERCIAL BOILERS and are NOT certified for use in domestic

applications. A domestic installation is defined as an installation

where the boiler takes its combustion air from a living space or

from a room directly or indirectly connected with the living space.

It is important, therefore, that no external control devices - e.g.

flue dampers, economisers etc., are directly connected to this

appliance unless covered by these Installation and Servicing

Instructions or otherwise recommended by Caradon Plumbing

Limited

in writing. If in doubt please enquire.

Any direct connection of a control device not approved by Caradon

Plumbing Limited

could invalidate the British Gas Certification,

the normal appliance warranty and could also infringe the Gas

Safety Regulations. Table 1, Table 2 and the descriptive notes

which follow contain all the essential data likely to be required by

the installer.

Concord CXC 48-116 (Natural gas)

B.G. Certified - P.I. No. 87/AQ/340

Destination Countries: GB and IE

Summary of Contents for Concord CXC 116

Page 1: ......

Page 38: ...38 Concord CXC Installation NOTES ...