43

Installation and Servicing

Section 3 - Servicing

SER

VICING

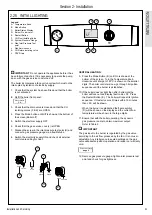

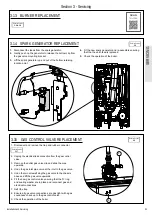

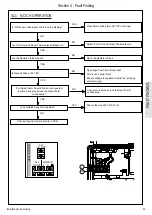

3.18 PRESSURE GAUGE REPLACEMENT

1. Drain the system.

2. Remove the boiler front (see section 3.2), lower the

control panel and remove the control box cover.

3. Ensuring there is no pressure in the system unclip the

C clip from the flow pipe port and remove the capillary

connection together with ‘O’ ring.

4. Releasing the two retaining clips on the pressure gauge ease

the pressure gauge through the front of the control panel.

5. Fit the new pressure gauge from the front of the lower

control panel ensuring correct orientation. Locate push fit

connection into flow pipe ensuring ‘O’ ring in place and

secure with the C clip.

6. Refill the boiler.

3

5

Refer to Section

3.2

Refer to Section

3.3

Refer to Section

2.17

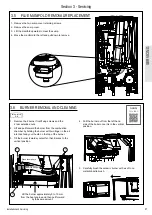

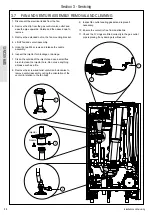

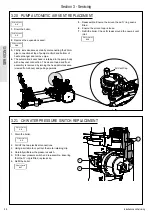

3.19 PRV REPLACEMENT

Refer to Section

3.2

Refer to Section

3.3

SCAN

for video

3

1. Drain the boiler.

2. Remove the trap and rubber pipe.

3. Pull out and remove the clip retaining the PRV.

4. Lift out the PRV/pipe assembly.

5. Remove the pipe and transfer to the new PRV.

6. Reassemble ensuring the retaining clip is correctly fitted.

7. Check the operation of the PRV by

raising the water pressure until the valve

lifts. This should occur within 0.3 bar of

the preset lift pressure.

8. Check no escape of water occurs except

at the discharge point

9. Release water from the system until the

minimum system design pressure is

reached; 1.0 bar if the system is to be pre-pressurised.

Refer to Section

2.17