34

Viscount GTS -

Installation & Servicing

INSTALLATION

220

90

VIS5112

1

2

3

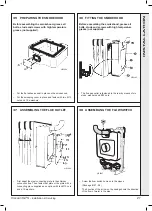

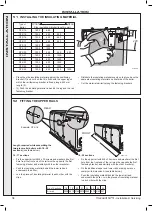

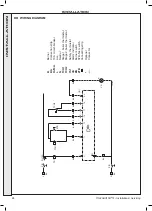

• Place the side insulating material against the positioning

bracket (1) and cut it so that it is flush with the upper lug on

which the rail fastening bracket is fixed, along a 220 mm

length (2).

• (3) Push the insulating material in behind the lug and the rail

fastening bracket.

• Distribute the insulating material evenly so that you have the

same side insulating material on either side of the boiler.

• Cut the material similarly along the fastening brackets.

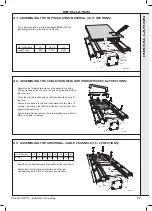

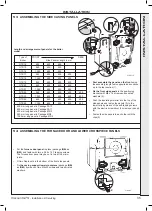

52 FITTING THE UPPER RAILS

A

REAR

FRONT

VIS5113

14 - 17 sections

• Fix the upper rail with M8 x 30 screws and washers (the first

hole from the front end of the rail must be opposite the first

fastening bracket, and similarly with the other brackets).

• Push the insulating material behind the lower rail and

underneath the boiler.

• Join the pieces of insulating material to each other with the

clips.

18 - 25 sections

• Fix the upper rail with M8 x 30 screws and washers (the first

hole from the front end of the rail must be opposite the first

fastening bracket, and similarly with the other brackets).

•

Fix the additional upper and lower rails, making sure you

comply with dimension A (see table below).

• Push the insulating material behind the lower rail and

underneath the boiler. Join the pieces of insulating material

to each other with the clips.

Length required while assembling the

two-piece rails (boilers with 18 - 25

sections)

(see table below).

No. of Sections

18 19 20 21 22 23 24

25

A (mm)

2500 2615 2765 2875 2965 3075 3165 3275

Type of

Boiler

GTS 14

1200

600

GTS 15

1200

400

400

GTS 16

1200

400

600

GTS 17

1200

400

600

GTS 18

1200

1200

GTS 19

1200

1200

GTS 20

1200

400

400

600

GTS 21

1200

400

1200

GTS 22

1200

400

1200

GTS 23

1200

600

1200

GTS 24

1200

600

1200

GTS 25

1200

400

400

1200

Side insulating material (length in mm)

FRONT

REAR

Example: GTS 16

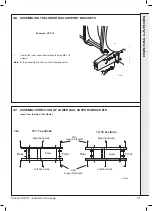

51 INSTALLING THE INSULATING MATERIAL

INST

ALLA

TION