INSTALLATION

19

Mexico Slimline CF440 -

Installation & Servicing

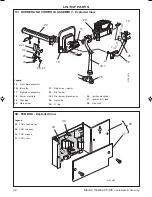

A. ELECTRICAL INSTALLATION

1.

Checks to ensure electrical

safety should be carried out by

a competent person.

2.

ALWAYS carry out preliminary

electrical system checks, i.e.

earth continuity, polarity,

resistance to earth and short

circuit using a suitable test

meter.

C. WATER CIRCULATING

SYSTEM

1.

The whole of the system

should be thoroughly flushed

out with cold water WITHOUT

the pump in position. Ensure

that all valves are open.

2.

With the pump fitted the

system should be filled and

air locks cleared. Check for

water soundness.

B. GAS INSTALLATION

1.

The whole of the gas installation,

including the meter, MUST be inspected

and tested for soundness, and purged in

accordance with the recommendations of

BS. 6891. In I.E. refer to I.S.813:2002.

2.

Purging air from the gas installation may

be expedited by loosening the union on

the gas service cock on the boiler and

purging until gas is detected.

3.

Retighten the union and check for gas

soundness.

WARNING.

Whilst effecting the required gas soundness test and purging air from the gas

installation, open all windows and doors, extinguish naked lights and

DO NOT SMOKE.

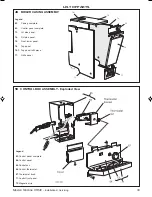

23 FITTING THE CASING

MEX 2281

3

1

4

7

1.

Offer up the LH side panel and secure the panel to

the baseplate and heat exchanger.

2.

Repeat step 1 to refit the RH side panel.

3.

Place the top panel on top of the side panels.

4.

Secure the top panel to the side panels.

IMPORTANT.

Wiring within the boiler casing must be neatly routed

and MUST NOT be allowed to touch the burner front

plate, cleanout cover or the collector hood.

Thermostat phial

Thermostat pocket

Phial retaining

clip

Split pin

MEX 729

24 COMMISSIONING AND TESTING

5.

Insert the thermostat phial into the thermostat pocket. Take

care not to kink the thermostat capillary as it is unwound,

and secure it with the split pin as shown.

6.

Replace the control box cover and refit the control panel

using the screws previously removed.

7.

Secure the PCB box to the casing side panels.

8.

Reconnect the PCB in-line connector, TTB thermostat in-

line connector and the Burner On neon cable.

The Benchmark Log Book or equivalent self certification should be completed and signed to demonstrate

compliance with Building Regulations.

INST

ALLA

TION

200946-1.p65

3/9/2004, 3:30 PM

19