Model 250

Printer Applicator

Operators/Technical Manual Section Five

Section 5 Page 7 of 18

2. Reverse - If you select the Reverse mode under the Print Sequence menu: Data is

downloaded to print engine buffer and resides there until required. When the

product detect photo-eye senses the product, the print engine is triggered and a

label is then printed and dispensed. As soon as the label is completely dispensed

onto the tamp pad or blow on grid the application is accomplished (tamp, blow -on,

etc…) At the end of the application cycle the printer awaits another trigger from the

photocell to start the process over. This continues until the quantity of labels

(designated by the operator) runs out. As the label is dispensed from the print

engine, the air assist will turn on. At the end of the dispense cycle, the air assist

will de-energize. While the dispense cycle is on the rewind cycle is on.

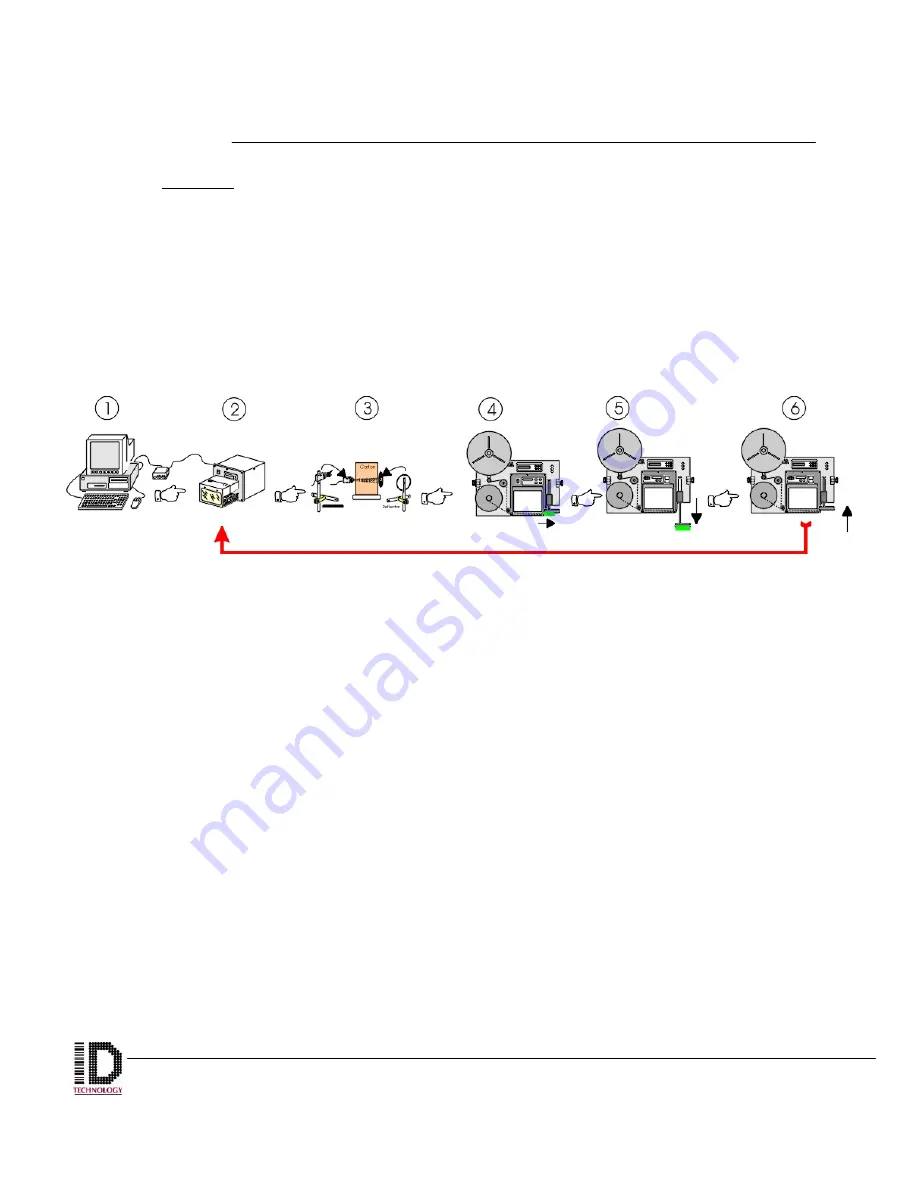

Figure 5-2

Reverse Print Sequence

1. Operator generates label and designates quantity.

2. Operator sends label to print engine’s buffer.

3. Product detector senses product and triggers print engine to print and

dispense a label.

4. Label is printed and dispensed.

5. Cylinder extends (or blow on pneumatics are initiated) and Label is

applied.

6. Cylinder retracts (or blow on pneumatics is de-energized)

7. Engine awaits another trigger from the product detector.

Cycle starts back at Print engine until designated quantity is completed.

Summary of Contents for 250

Page 1: ...250 Print and Apply Operator Technical Manual Model...

Page 69: ...Model 250 Printer Applicator Operators Technical Manual Section 3B Section 3B Page 9 of 9...

Page 110: ...Model 250 Printer Applicator Operators Technical Manual Section Six Section 6 Page 17 of 20...

Page 111: ...Model 250 Printer Applicator Operators Technical Manual Section Six Section 6 Page 18 of 20...

Page 112: ...Model 250 Printer Applicator Operators Technical Manual Section Six Section 6 Page 19 of 20...

Page 127: ...2051 FRANKLIN DR FORT WORTH TX 76106 250 PRECISION TILT...