SERVICE AND TECHNICAL SUPPORT MANUAL

Gas Furnace: N9MSB

Specifications subject to change without notice.

24

440 04 4412 01

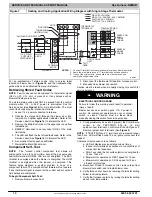

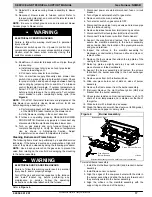

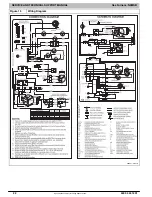

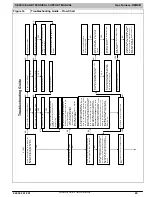

Figure 16 (CONT.) Troubleshooting Guide

−

Flow Chart

1

+ 2

BL

O

W

ER ON AF

T

E

R PO

W

E

R UP

–

(11

5

V

OR

24V

)

–

No

rm

al o

p

e

rati

o

n.

Blower

r

u

ns f

o

r 9

0

se

c

o

n

d

s, if

u

n

it is

po

w

e

re

d u

p

duri

ng

a c

a

ll f

o

r

hea

t (R

-

W

/W

1

closed)

or

whe

n (

R

-W

/W

1 opens

)

d

u

ri

n

g

t

h

e b

low

er

on

-d

e

la

y

pe

ri

od

.

6 + 1

IGN

IT

IO

N

LOCK

OUT

–

S

y

st

e

m

fa

iled

to

ignite

g

a

s a

n

d

pr

ove

flam

e i

n

4

attem

p

ts. C

o

n

trol

w

ill

a

u

to

-r

eset

af

ter

3

hou

rs.

Ref

er

to s

tat

us c

o

d

e

#

6

.

5 ABNOR

M

A

L

F

L

A

M

E

-PROV

IN

G

S

IGN

AL

F

lam

e is

pr

ov

ed

while

gas

valv

e is

de

-

ene

rgi

zed.

Indu

cer

w

ill r

un

until

fa

ult is

clear

e

d

. C

h

eck

fo

r:

-

S

tuck

ope

n

or l

e

ak

y

ga

s val

v

e.

2

PRESSURE S

W

IT

CH DI

D N

O

T O

PEN

–

Check

fo

r:

- Obst

ruct

ed

pr

ess

u

re

tu

be.

-

P

re

s

su

re

sw

it

ch

s

tu

c

k c

lo

s

ed

.

3

L

PS o

r HPS PRESSURE S

W

IT

CH DID

NOT

CLOSE

OR REOPENE

D

–

If

o

p

e

n

s

duri

ng blo

wer on

-d

ela

y

pe

rio

d

,

bl

o

w

e

r w

ill

com

e

o

n

f

o

r t

h

e

se

le

cte

d

b

lo

w

e

r

off-del

a

y

.

If

LP

S

ope

n

lo

ng

er

th

an

5 m

inu

tes,

induc

er

sh

uts

off f

o

r 15

m

inut

es

bef

o

re

ret

ry

.

If HP

S

ope

n f

o

r

on

e m

inu

te,

th

en

fur

nac

e

w

ill lo

ck

out (

a

ft

er

th

e su

ccessi

v

e

trials

) fo

r t

h

re

e

ho

urs

be

for

e

r

e

tr

y

.

Check

fo

r:

-

P

rop

er

v

e

n

t

si

z

in

g

.

-

A

ir leak

b

e

tw

e

e

n

vesti

bul

e a

n

d

blo

wer

com

p

a

rtm

ent

.

-

Lo

w

i

n

let

ga

s p

ress

u

re

(if

L

G

P

S

us

ed)

.

-

Discon

n

ec

ted

o

r o

b

str

u

ct

ed

pr

essu

re

tubi

ng.

-

Defec

tive

or m

is

w

ir

e

d

p

ress

u

re

s

w

it

ch

e

s

- Ex

c

e

ssiv

e

w

in

d

.

- P

lug

ge

d

c

o

nd

en

s

a

te

d

ra

in

-

W

a

ter in

ve

nt pi

pin

g, p

o

ssi

ble s

a

g

g

in

g

pi

pe

- Restri

cte

d

ve

nt.

- Defec

tive

Ind

u

c

e

r

m

o

to

r.

-

Lo

w

i

n

d

u

ce

r vol

tag

e

(11

5

VAC)

4 L

IM

IT

C

IRCU

IT

F

A

ULT

–

I

n

dica

te

s

th

e

lim

it, flam

e r

o

llo

u

t

is

op

en.

B

lo

wer

w

ill

r

un

for

4 m

in.

or

un

til o

p

en

s

w

itc

h

r

e

m

a

k

e

s

which

e

ve

r is l

ong

er

.

If

op

en

lon

ge

r t

h

a

n

3

m

in, cod

e

c

h

a

n

g

e

s t

o

lock

ou

t #

7

.

If o

p

en

less t

h

an

3 m

in

. st

atus

co

de

#4

con

tin

u

e

s

to fla

s

h

until

blo

w

er

sh

uts

off.

Fl

am

e

roll

o

ut s

w

it

ch

re

qui

res m

a

nu

al r

e

se

t.

Check

fo

r:

-

Loo

s

e blo

wer

whe

el.

-

Defec

tive

s

w

itch

o

r co

nn

ectio

n

s.

-

Dirt

y

filt

er

or

r

e

str

ic

te

d

d

u

ct s

y

stem

.

-

Im

p

ro

per

g

a

s in

put

a

d

justm

e

nt

-

Im

p

ro

p

er

lim

it s

w

itc

h

o

r n

o

lim

it g

a

sk

et

T

o

det

e

rm

in

e

w

h

et

her

th

e p

ro

b

lem

is i

n

the

gas

valv

e, i

g

nit

er,

or

flam

e

sen

s

o

r t

h

e

s

y

stem

c

an be op

er

ate

d

in com

p

one

nt

test m

o

de.

T

o

c

h

eck

th

e ig

nite

r,

rem

o

v

e

the R

th

erm

o

s

tat

co

nne

c

tio

n

fr

om

th

e

cont

rol,

re

set po

wer

,

st

art the

com

p

on

e

n

t

test.

Do

es t

he i

gnit

e

r

glo

w

o

ran

ge

/w

hit

e

b

y

th

e

end

of

th

e 1

5

s

e

co

nd

warm

-up

peri

o

d

?

Unplu

g ig

nit

er

har

n

e

ss f

rom

co

nt

rol

and

rep

e

at

com

p

on

ent

tes

t. C

heck

fo

r 1

1

5

V

bet

wee

n co

nn

ect

o

r P

2

(HS

I) a

n

d

NE

UT

RA

L-L

2

o

n

t

h

e c

ont

rol

.

W

a

s 115

V

pres

en

t

fo

r

the 15 sec

o

n

d

p

e

ri

od?

Check

co

nn

ectio

n

s

and

r

e

tr

y

.

If

cu

rr

ent i

s

n

e

ar

t

y

pi

cal v

a

lu

e

(4.

0

-6

.0

A

DC

nom

in

al)

an

d

bur

ne

rs

w

ill

not

sta

y

o

n

,

repl

ace

co

ntr

o

l.

Clean

flam

e

se

nso

r

w

it

h

fin

e

st

eel

wool

and

r

e

che

c

k

curr

en

t. N

o

m

inal

cur

re

n

t i

s

4.0 to 6.0

A DC.

Is

cu

rre

nt

ne

ar

ty

pic

a

l v

a

lue

?

Repla

c

e elect

ro

d

e.

W

ill m

a

in bur

ner

s ig

nite

an

d st

a

y

on

?

Repla

ce f

u

rn

ac

e c

ont

rol.

Fi

x

e

d.

NO

Y

ES

Y

ES

Y

ES

NO

NO

Repla

ce f

u

rn

ac

e c

ont

rol.

Check

fo

r co

nti

nuit

y

i

n

t

h

e

har

nes

s a

n

d i

g

nit

e

r.

Re

plac

e

def

ective

com

p

on

ent

.

Reco

n

n

e

ct t

he

R th

erm

o

s

tat

lea

d

and

s

e

t

the

rm

o

sta

t to

call

for

h

eat.

Co

nn

ect

voltm

e

te

r acr

o

ss gas valv

e

co

nn

ecti

ons

.

Does

gas

valv

e r

e

c

e

ive

24V

?

Does

gas

valv

e

ope

n a

n

d

allo

w g

a

s t

o

flo

w

?

Do th

e m

a

in

b

u

rn

er

s ig

nite

?

Do th

e m

a

in

b

u

rner

s st

a

y

o

n

?

A

llow blo

wer

to

com

e

on

an

d

rep

e

at

tes

t t

o

ch

eck

for

interm

itt

en

t o

p

e

rati

o

n.

Check

th

at

gas

valv

e el

ectri

c

sw

it

ch is

tu

rn

ed

on.

Re

plac

e

valve.

Che

ck

co

nn

ectio

n

s. I

f OK,

repl

ace

co

ntr

o

l.

Check

fo

r:

-

Ina

deq

ua

te fl

am

e c

a

rr

y

ov

er

or rou

g

h

igni

tion

.

-

Lo

w

i

n

let

ga

s p

ress

u

re

.

- Prop

er

firin

g

r

a

te

.

Repe

a

t c

a

ll f

o

r

he

at

and

ch

eck

flam

e

sens

or c

u

rr

e

n

t

duri

ng

trial

fo

r ig

nitio

n

peri

od.

I

s

t

h

e DC

c

u

rr

en

t

b

e

lo

w

0.5

A?

Y

ES

Y

ES

Y

ES

Y

ES

Y

ES

NO

NO

NO

NO

NO

NO

6 IGN

IT

IO

N

P

R

OV

IN

G

F

A

IL

URE

–

I

f fla

m

e is

not s

e

n

s

ed

d

u

ri

n

g

t

h

e

trial

fo

r ig

nitio

n

peri

o

d,

th

e c

ont

rol

w

ill

re

pe

at t

h

e i

g

niti

o

n

seq

u

en

ce

3 m

o

re

tim

e

s

be

fo

re l

o

ck

out

#6 +

1 occ

u

rs

.

If flam

e

sig

n

al is

lost

d

u

rin

g

t

h

e

blo

w

e

r

on-

d

el

a

y

p

e

ri

od,

blo

w

er

w

ill c

o

m

e

o

n

for

th

e

sel

e

cte

d

blo

wer off-

del

a

y

.

Ch

ec

k

th

e fo

llo

w

ing

be

for

e

goin

g t

o

t

he

ne

xt st

ep.

-

Gas

v

a

lve

tu

rn

ed

off

.

- Man

ual

sh

ut-

o

ff v

a

lve

o

pen

?

-

Gre

e

n/

Y

e

llo

w

w

ire

M

U

S

T

be

c

o

n

nect

e

d

to f

u

rn

ace

sh

eet

m

e

tal.

-

Flam

e s

e

n

s

or

m

u

st

not

be

gr

ou

nd

ed.

10

P

O

LA

R

IT

Y

–

Che

ck

for c

o

rr

ec

t lin

e

volta

g

e

pol

arit

y

.

If

u

n

its

are

t

w

in

ne

d,

check

fo

r p

ro

p

e

r lo

w

-volt

ag

e (

24V

)

tra

n

sfo

rm

e

r ph

asin

g.

7 L

IM

IT

C

IRCU

IT

LOCKOUT

–

Lo

c

k

o

u

t

occu

rs if

th

e lim

it, flam

e

r

o

llou

t is

ope

n

long

er tha

n

3

m

inut

e

s.

Co

ntr

o

l w

ill aut

o-

rese

t a

fte

r 3

ho

urs

. R

e

fe

r t

o

st

atu

s

co

d

e

#4.

8 GAS

HEAT

IN

G

L

O

CKOUT

–

Co

ntr

o

l

w

ill

NOT

aut

o

res

e

t. T

u

rn

off

p

o

w

e

r a

nd

wait

5 m

inut

es t

o

r

e

tr

y

. C

heck

f

o

r:

-

Stuck

close

d

g

a

s v

a

lve

r

e

la

y

on

con

tr

o

l.

-

Mis

w

ir

e o

r s

hor

t t

o

g

a

s v

a

lve

w

ire

.

Y

ES

unless

noted

on

switch.

L12F045