Maintenance, troubleshooting, spare parts and dismantling

34

iDRY iRDP CT 20-500

Dew point too high.

The compressor does not work – see specific point.

The DewPoint probe T1 doesn’t correctly detect the temperature - ensure the sensor

is pushed into the bottom of probe well.

The ambient temperature is too high or the room aeration is insufficient - provide

proper ventilation.

The inlet air is too hot – restore nominal conditions.

The inlet air pressure is too low – restore nominal conditions.

The inlet air flow rate is higher than the rate of the dryer - reduce the flow rate - restore

nominal conditions.

The condenser is dirty – clean it.

The condenser fan does not work – see specific point.

The dryer does not drain the condensate – see specific point.

If ESS=NO (see section 8.12.7) – The hot gas bypass valve is out of setting – contact a ICP

service technician to restore nominal setting.

If ESS=YES (see section 8.12.7) – DewPoint on this type of dryer is fluctuating (the

compressor turns ON and OFF) and for some periods can reach values higher than normal

- wait for the compressor start and the DewPoint will drop to lower temperature.

The solenoid valve EVL is not operating correctly - see specific point.

There is a leak in the refrigerant circuit – contact a ICP service technician.

Dew point too low

with parameter

ESS=NO

(see section 8.12.7)

The fan is always ON – verify the electric wiring, check the setting of PV pressure switch or

PV pressure switch is faulty – contact a ICP service technician to replace it.

The ambient temperature is too low – restore nominal conditions.

The hot gas bypass valve is out of setting – contact a ICP service technician to restore

nominal setting.

Dew point too low

with parameter

ESS=YES

(see section 8.12.7)

DewPoint on this type of dryer is fluctuating (the compressor turns ON and OFF) and

for some periods can reach values lower than normal - wait until the DewPoint rise to

normal temperature.

The refrigerating compressor is always ON, even though the led

is OFF – verify

the electric wiring or KC relay (if installed) is faulty – replace it.

Excessive

pressure

drop within the dryer.

The dryer does not drain the condensate – see specific point.

The dew point is too low – the condensate is frozen and blocks the air – see specific point.

If ESS=YES (see section 8.12.7) – The DewPoint probe T1 doesn’t correctly detect the

temperature and the condensate freeze– ensure the sensor is pushed into the bottom

of probe well.

Check for throttling the flexible connection hoses.

The dryer does not

drain the condensate.

The condensate drain service valve is closed – open it.

Verify the electric wiring.

The dew point is too low – the condensate is frozen and blocks the air – see specific point.

The iMAT condensate drain does not work correctly (see iMAT MANUAL).

Inlet compressed air pressure is too low and the condensate is not drained – restore

nominal conditions

The dryer continuously

drains the condensate.

Please read the separate iMAT installation and operating instructions.

Water within the line.

If installed - untreated air flows through the bypass unit – close the bypass.

The dryer does not drain condensate – see specific point.

Dew point too high – see specific point.

The compressed air pipeline downstream of the dryer are located at a very low ambient

temperature and the remaining humidity in the compressed air is condensing: is required to

review the plant compressed air distribution system.

If ESS=YES (see section 8.12.7) – DewPoint on this type of dryer is fluctuating (the

compressor turns ON and OFF). In low ambient temperature condition (winter season) the

remaining humidity in the compressed air is condensing. Set ESS=NO (see section 8.12.7)

Summary of Contents for iDRY iRDP CT 100

Page 29: ...Technical data iDRY iRDP CT 20 500 29 11 2 Technical data iDRY iRDP CT 20 500 2 1 230 60...

Page 38: ...Maintenance troubleshooting spare parts and dismantling 38 iDRY iRDP CT 20 500...

Page 39: ...Maintenance troubleshooting spare parts and dismantling iDRY iRDP CT 20 500 39...

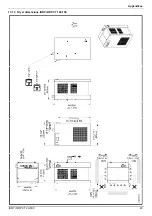

Page 42: ...Appendices 42 iDRY iRDP CT 20 500 13 1 2 Dryer dimensions iDRY iRDP CT 75...

Page 43: ...Appendices iDRY iRDP CT 20 500 43 13 1 3 Dryer dimensions iDRY iRDP CT 100 150...

Page 44: ...Appendices 44 iDRY iRDP CT 20 500 13 1 4 Dryer dimensions iDRY iRDP CT 200 250...

Page 45: ...Appendices iDRY iRDP CT 20 500 45 13 1 5 Dryer dimensions iDRY iRDP CT 300 350...

Page 46: ...Appendices 46 iDRY iRDP CT 20 500 13 1 6 Dryer dimensions iDRY iRDP CT 400 500...

Page 47: ...Appendices iDRY iRDP CT 20 500 47 13 1 7 Dryer dimensions iDRY iRDP CT 200 250 3phase...

Page 48: ...Appendices 48 iDRY iRDP CT 20 500 13 1 8 Dryer dimensions iDRY iRDP CT 300 350 3phase...

Page 49: ...Appendices iDRY iRDP CT 20 500 49 13 1 9 Dryer dimensions iDRY iRDP CT 400 500 3phase...

Page 51: ...Appendices iDRY iRDP CT 20 500 51 13 2 2 Exploded diagram iDRY iRDP CT 20 30...

Page 52: ...Appendices 52 iDRY iRDP CT 20 500 13 2 3 Exploded diagram iDRY iRDP CT 50...

Page 53: ...Appendices iDRY iRDP CT 20 500 53 13 2 4 Exploded diagram iDRY iRDP CT 75...

Page 54: ...Appendices 54 iDRY iRDP CT 20 500 13 2 5 Exploded diagram iDRY iRDP CT 100...

Page 55: ...Appendices iDRY iRDP CT 20 500 55 13 2 6 Exploded diagram iDRY iRDP CT 125 150...

Page 56: ...Appendices 56 iDRY iRDP CT 20 500 13 2 7 Exploded diagram iDRY iRDP CT 200 250...

Page 57: ...Appendices iDRY iRDP CT 20 500 57 13 2 8 Exploded diagram iDRY iRDP CT 300 350...

Page 58: ...Appendices 58 iDRY iRDP CT 20 500 13 2 9 Exploded diagram iDRY iRDP CT 400 500...

Page 59: ...Appendices iDRY iRDP CT 20 500 59 13 2 10 Exploded diagram iDRY iRDP CT 200 250 3phase...

Page 60: ...Appendices 60 iDRY iRDP CT 20 500 13 2 11 Exploded diagram iDRY iRDP CT 300 350 3phase...

Page 61: ...Appendices iDRY iRDP CT 20 500 61 13 2 12 Exploded diagram iDRY iRDP CT 400 500 3phase...