11

ICE RS26L / RS28L / RS32L

OPERATOR MANUAL

WaRnInG: Before performing any

maintenance on the machine, be sure that

the power is turned off, or the batteries are

disconnected!

WARING: Repairs are to be completed

by Authorized service centers only. Any repairs

completed by unauthorized persons will avoid

the warrenty.

daIly maIntenance

1. Remove pad driver/ brush and clean with

approved cleaner.

2. Drain recovery and solution tanks completely

and rinse out with clean water. Visually check

the recovery tank for debris and clean out as

necessary.

3.

Raise the squeegee assembly off floor and wipe

it down with a damp towel. Be sure to store the

squeegee in the up position.

4.

Remove the vacuum fan inlet filter and rinse it

out with clean water.

5. Clean machine with an approved cleaner and a

damp towel.

6. Recharge the batteries.

7. Check the condition of the squeegee blade

wiping edge, rotate blade if worn.

montHly maIntenance

1. Clean the battery tops to prevent corrosion.

2. Check for loose battery cable connections.

3. Inspect and clean the recovery tank cover seal.

Replce it if damaged.

4. Lubricate all grease points and pivot points with

silicon spray and approved grease.

5. Check the machine for loose nuts and bolts.

6. Check the machine for leaks.

macHIne StoRaGe

1. Always store the machine indoors.

2. Always store the machine in a dry area.

3. Always store the machine in its upright position.

4. Always store the machine with the pad driver/

brush raised off the floor.

5. Always store the machine with the squeegee

assembly raised off the floor.

6. If storing in an area which may reach freezing

temperatures, be sure to drain all fluids from the

machine prior to storage. Any damage caused

by freezing temperatures will not be covered by

the warranty.

7. Drain the recovery tank.

8. Drain the solution tank of all fluid.

pReVentatIVe maIntenance

FAULT CODE & SOLUTION

The machine is equipped with a LED display

screen (see Machine components, item # 31), the

LED screen will display the operating hours (see

Machine components, item # 35) and the battery

level status (see Machine components, item # 30).

When the machine detects a fault, there will be a

Fault code (see Machine components, item #33)

& Fault message (see Machine components, item

#34) display on the LED screen, and the Fault

indicator (see Machine components, item #32) will

flash continuously, accompany an audible alarm

Occasionally.

Once fault occuring, please DO NOT continue

operate the machine unless the fault are eliminated.

Turn off the machine, then to solve the fault, the

fault code & message will be eliminated when

machine restart.

If the fault is occurred frequently, or the fault can't

be eliminated, please contact ICE service center.

Please refer to the below table to determine the

fault cause and the solution.

Summary of Contents for RS26L

Page 14: ...14 ICE RS26L RS28L RS32L PARTS LIST MAIN FRAME GROUP ...

Page 16: ...16 ICE RS26L RS28L RS32L PARTS LIST STEERING DRIVE WHEEL GROUP ...

Page 18: ...18 ICE RS26L RS28L RS32L PARTS LIST SOLUTION TANK GROUP ...

Page 20: ...20 ICE RS26L RS28L RS32L PARTS LIST RECOVERY TANK GROUP ...

Page 22: ...22 ICE RS26L RS28L RS32L PARTS LIST RECOVERY TANK COVER GROUP ...

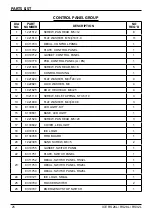

Page 24: ...24 ICE RS26L RS28L RS32L PARTS LIST CONTROL PANEL GROUP ...

Page 26: ...26 ICE RS26L RS28L RS32L PARTS LIST MAIN CONTROLLER GROUP ...

Page 28: ...28 ICE RS26L RS28L RS32L PARTS LIST SEAT DETERGENT SYSTEM GROUP ...

Page 30: ...30 ICE RS26L RS28L RS32L PARTS LIST BATTERY GROUP ...

Page 32: ...32 ICE RS26L RS28L RS32L PARTS LIST SCRUB HEAD LIFTING GROUP ...

Page 34: ...34 ICE RS26L RS28L RS32L PARTS LIST SCRUB HEAD GROUP ...

Page 36: ...36 ICE RS26L RS28L RS32L PARTS LIST SQUEEGEE GROUP ...

Page 38: ...38 ICE RS26L RS28L RS32L PARTS LIST SOLUTION DETERGENT SYSTEM ...