INSTALLATION AND OPERATION INSTRUCTIONS

1-20

HC SERIES BOILERS

HC 13-50, HC 23-84, HC 29-106, HC 33-124, HC 20-125, HC 33-160

The HC series modulating boilers are designed for use within a closed loop,

forced circulation, low pressure system. A 30 PSI pressure relief valve (3/4" NPT)

is supplied for field installation at the boilers top connection point. A Relief Valve

and Air Vent Piping Kit is also included with each HC series boiler to aid in the

proper installation of the relief valve and air vent.

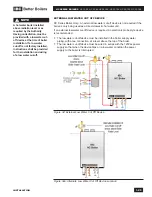

System piping is connected to the boiler using the 1" NPT Male threaded fittings

located on the bottom of the boilers. Unions and gate or ball valves at the boilers

supply and return water connections are recommended to simplify servicing. Un-

insulated hot water pipes must be installed with a minimum 1/4" clearance from

combustible materials.

Fluid fill is most often accomplished by using a boiler regulator & fill valve set

at 12 psig or more, with appropriate backflow prevention device as required

by local code. This is acceptable in areas where municipal water or well water

has been treated and filtered to remove excessive minerals and sediment, and

water chemistry is known to be suitable for closed loop hydronic systems. In

areas where water quality is in question, or when chemical treatment or glycol is

required, other options should be considered. Follow applicable Codes and good

piping practice.

There are a number of boiler feed and pressurization devices on the market

today that may be a better choice than a raw water fill from the mains. When

regular maintenance requires relief valve blow-off, the discharge may be directed

back into the pressurization unit for recycling of boiler fluid and chemicals

back into the system. In buildings that may be unoccupied for long periods of

time, pressurization units are useful to prevent flood damage should leakage

occur from any component in the system. An additional benefit is that backflow

prevention devices are not required when using these devices.

CAUTION

Installers should inquire of

local water purveyors as to the

suitability of their supply for use

in hydronic heating systems. If

water quality is questionable,

a local water treatment expert

must be consulted for testing,

assessment and, if required,

treatment.

Alternatively, water or hydronic

fluid of known quality can be

brought to the site.

WARNING

During operation, the relief

valve may discharge large

amounts of steam and/or hot

water. Therefore, to reduce the

potential for bodily injury and

property damage, a discharge

line MUST be installed that it:

1.

is connected from the

valve outlet with no

intervening valve and

directed downward to a

safe point of discharge.

2.

allows complete drainage

of both the valve and the

discharge line.

3.

is independently supported

and securely anchored so

as to avoid applied stress

on the valve.

4.

is as short and straight as

possible

5.

terminates freely to

atmosphere where any

discharge will be clearly

visible and is at no risk of

freezing.

6.

terminates with a plain end

which is not threaded.

7.

is constructed of a material

suitable for exposure to

temperatures of 375°F or

greater.

8.

is, over its entire length,

of a pipe size equal to or

greater than that of the

valve outlet.

DO NOT CAP, PLUG OR

OTHERWISE OBSTRUCT THE

DISCHARGE PIPE OUTLET!

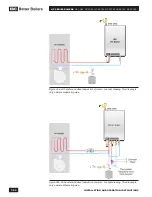

Figure 23: Relief Piping