11

INSTALLATION AND OPERATION INSTRUCTIONS

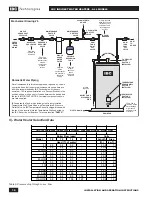

IBC INDIRECT WATER HEATERS - ALL MODELS

It is recommended that the thermostat be set for the lowest possible temperature

that satisfies your needs. This will also provide you with the lowest energy

consumption and cost.

Check the water temperature at a hot water faucet soon after the tank thermostat

has satisfied, and the circulator and the boiler have turned off. Adjust as needed.

Lowering the thermostat setting will not have an immediate effect on the water

temperature because the stored water will have to be used and the thermostat

must go through the cycle of heating cold water and satisfying at the new, lower

temperature. Additional temperature checks should follow the completion of a

heating cycle. Further adjustments may be required after you have used the

water heater.

6) - Maintenance

The water heater is intended to provide many years of reliable service.

Components, such as sensors and relief valves, may be subject to failures that

require service. Depending on the quality of the water supply, sediment and/or

scale may coat the heating coil in the tank and reduce hot water recovery rate.

Failure to use the correct procedures or parts can result in unsafe operation.

The owner should arrange to have the following inspections and simple

maintenance procedures done at the suggested frequencies.

1. Boiler and Domestic Water Piping (Annual)

Check all piping for signs of leakage at the joints, unions and shut-off valves.

Repair as required.

2. Temperature and Pressure Relief Valve (Annual)

3. Sediment (Annual except where harsh water quality may require more

frequent service)

Depending on water conditions, a varying amount of sediment may collect

in the tank. Levels requiring service are indicated by a small temperature

difference between the boiler supply and return lines, and a reduced recovery

rate. Repeated flushing usually clears such material. As a preventive

measure, water should be drawn from the drain valve until it runs clear and

the installation of a water filter should be considered.

4. Scale (Annual)

Hard water may cause scale buildup on the outside of the heating coil

inside the tank. A water softener will help prevent this problem. Symptoms

are identical to sediment buildup. If repeated flushing does not resolve the

problem, chemical cleaning may be required. Proceed as follows:

Chemical cleaning of the heating coil:

1. To avoid water damage, shut off the cold water supply to the water heater.

2. Make a note of the DHW temperature control setting on the IBC control,

and turn off the power to the boiler and water heater.

3. Relieve the water pressure in the tank by opening a hot water faucet. This

will reduce the risk of scalding.

4. Remove the relief valve from the water heater.

5. Drain the water heater until the water is at a level equal to 3” above the

thermostat well. This level will cover the coil and the thermostat.

CAUTION

As a precaution:

After the water heater

has reached its setpoint

temperature, the installer

should locate a faucet that

is unprotected by an over-

temperature device.

Turn the faucet on full, and

allow it to run long enought to

ensure the water and piping

have been heated up to the

discharge temperature of the

tank.

Using an accurate

thermometer, test the water

temperature to ensure it is

withing plus or minus 10°F of

the setpoint. If there is more

deviation, the cause should

be determined and corrective

measures taken.