MAN-052

21

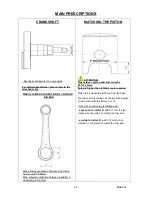

- INSERT CRANKSHAFT AND CLOSE

CRANKCASE HALVES (see Fig.10).

-

ASSEMBLE CRANKCASE HALVES

N°9 SCREWS M6 (see Fig.11).

(CROSS PATTERN LOCKING – (SEE

ATTAC HED SKETCH)

TORQUE AT 8÷10 Nm (70 ÷ 90 lbf*in)

(5mm ALLEN WRENCH – T TYPE)

3.

FITTING OIL SEALS

- APPLY SPECIAL LUBRICANT ON SEAL LIPS.

(APPLY MORE LUBRICANT BETWEEN THE

OUTER AND INNER OIL SEAL LIPS)

ATTENTION:

WHEN FITTING NEW SEALS, TURNING THE

CRANKSHAFT COULD RESULT MORE

DIFFICULT, BUT THIS IS NORMAL.

- FIT SEALS ON CRANKSHAFT BY USING THE

SPECIAL TOOL WITH BUSHING, TO BE

INSERTED ON THE CRANKSHAFT (GEAR

SIDE) (P.N. 10295A)

(see Fig.13).

(MARK ON SEAL TO BE TURNED TOWARDS

OUTSIDE).

- INSERT OIL SEAL IN GEAR COVER USING

THE SPECIAL TOOL (P.N. 10296)

(MARK ON SEAL TO BE TURNED TOWARDS

OUTSIDE).

ATTENTION:

OIL SEALS MUST ALWAYS BE REPLACED

WHEN DISASSEMBLED.

Fig.12

Fig.11

Fig.13

Fig.10

ATT.: screw

starter side

Summary of Contents for Parilla Reedster 125cc

Page 1: ...07 11 07 MAN 052 1 OVERHAULING MANUAL REEDSTER 125cc versions F1 F2 F3 F4 21 01 2009...

Page 36: ...MAN 052 34 COUPLES ON TIGHTENING OF NUTS AND SCREWS...

Page 37: ...MAN 052 35 CROSS PATTERN LOCKING ORDER ON CRANKCASE...

Page 39: ...MAN 052 37...

Page 42: ...MAN 022 40 FIXING ENGINE TOOL ON BENCH VICE 40...