●

Interface Area

●

Node Address Setting

Node address can be set with the parameter.

Set Parameter No. 85 “NADR : Fieldbus Node Address” with using the

PC software for RC.

Available range for Setting : 3 to 239 [hex] (setting at delivery : 3)

●

Data Length Setting

Establish the setting in Parameter No. 86 “FBRS : Fieldbus

Communication Speed” in RC PC software considering the data length

to be used.

Setting Value

Data Length

Baud Rate

0 32

bytes

1 (at the delivery)

48 bytes

100Mbps

●

Electronic Gear Ratio

Setting

Set the electronic gear numerator in Parameter No. 65 “CNUM : Electronic Gear Numerator” and the electronic gear

denominator in No. 66 “CDEN : Electronic Gear Denominator”. In the RC PC software

Establish the settings to satisfy the following condition:

Stroke [mm]

Electronic Gear Ratio Denominator

Ball Screw Lead Length [mm]

Electronic Gear Ratio Numerator

●

Pulse Count Direction Setting

Set the value in Parameter No. 62 “FPIO : Pulse Count Direction” to be the same as what is set in No. 5 “ORG :

Home-Return Direction” in the RC PC software.

(Note)

Reboot the power on the controller after the parameter settings are completed, and make sure to put the

switchover switch on the front face of the controller back to the AUTO side.

●

Wiring

Connect the dedicated cable for MECHATROLINK.

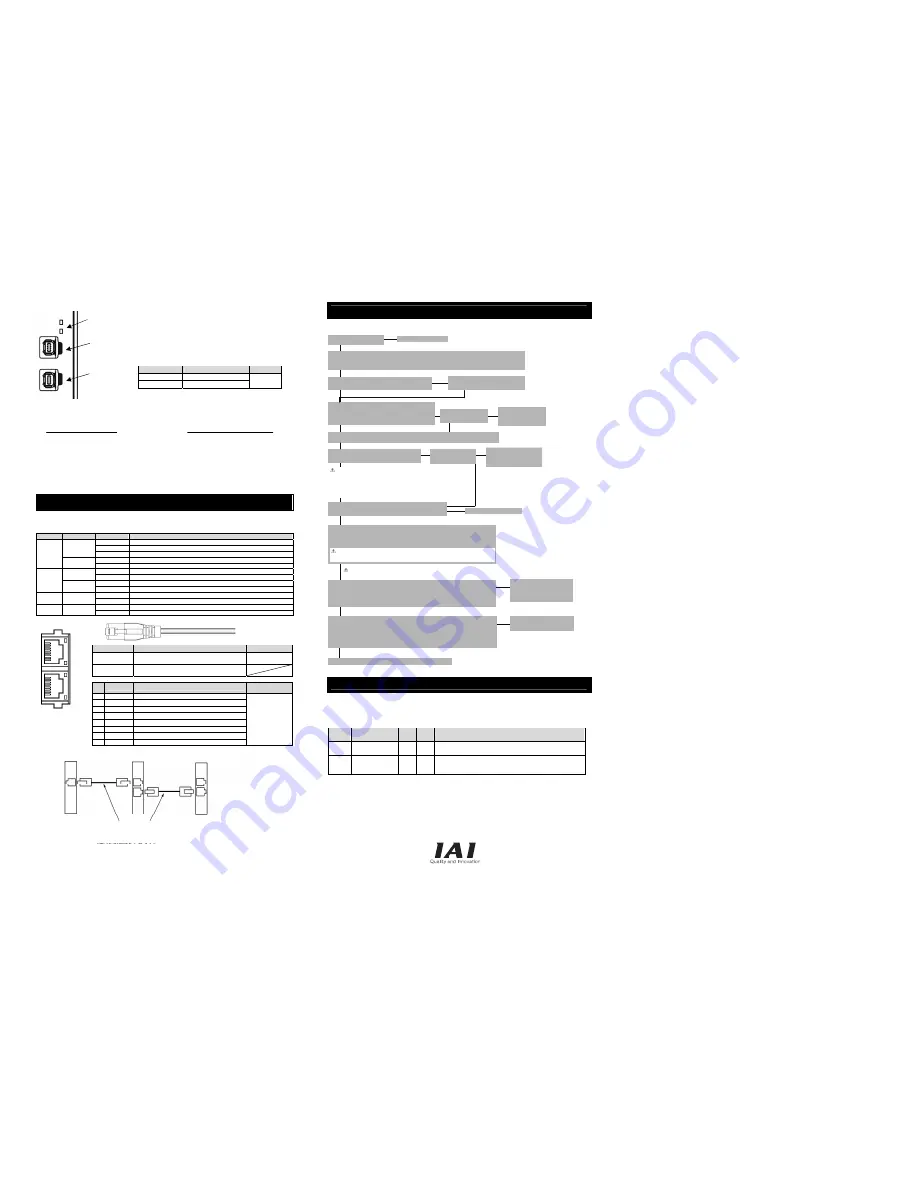

CC-Link IE (Dedicated for SCON-CB/CGB)

●

Specification

Refer to the CC-Link IE Instruction Manual

●

Status LED

LED

Color

Illumination Status

Explanation

Steady Light

Cyclic transmission in process

Blinking

Cyclic transmission paused

GN: D LINK

Off

Cyclic transmission not conducted, parallel off, Power not supplied

Steady Light

Received data in error

NS

OR: L ERR

Off

Received data in normal conditions, Power not supplied

Steady Light

Operation in normal conditions

GN: RUN

Off

Hardware error occurred, Power not supplied

Steady Light

Error being occurred (Node Error / Station Number Setting Error)

MS

OR: ERR

Off

Operation in normal conditions, Power not supplied

Steady Light

Linkup in process

LINK GN

Off

Link-down in process, Power not supplied

Steady Light

Received data in error

L.ER OR

Off

Received data in normal conditions, Power not supplied

●

Interface Area

Connector Name

CC-Link IE Connector

Remarks

Cable Side

Ethernet ANSI/TIA/EIA-568-B Category 5e and above

8P8C modular plug equipped with shield (RJ45)

Please prepare

separately

Controller Side

Ethernet ANSI/TIA/EIA-568-B Category 5e and above

8P8C modular Jack equipped with shield (RJ45)

Pin

No. Signal Name

Description

Applicable cable

diameter

1 TP0+

Data

0+

2 TP0-

Data

0-

3 TP1+

Data

1+

4 TP2+

Data

2+

5 TP2-

Data

2-

6 TP1-

Data

1-

7 TP3+

Data

3+

8 TP3-

Data

3-

It is recommended to

prepare a straight

STP cable in

Category 5e or above

for the Ethernet

cable.

●

Wiring

Starting Procedures

When using this product for the first time, make sure to avoid mistakes and incorrect wiring by referring to the

procedure below. “PC” stated in this section means “PC software”.

Trouble Shooting

In the case an error is occurred, check the operation status on the LED display on the front panel [Refer to

Each Fieldbus Section], and also, check the status monitor by connecting a teaching tool such as PC software

for RC.

Either of the following alarms will be shown for Fieldbus. Please refer to the Instruction Manual of the controller

for other alarms to perform an appropriate treatment.

Code

Error Name

ID

(*1)

RES

(*2)

Cause / Treatment

0F2

Fieldbus

Module Error

05

×

Cause

: An error is detected on Fieldbus module

Treatment : Check on the parameter

0F3

Fieldbus Module

Not Detected

04

×

Cause

: Module cannot be detected

Treatment : Turn the power off and reboot. Please contact us

if the problem is not solved with this action.

(*1) ID

→

Simple alarm code

(*2) RES

→

Alarm reset available/unavailable

○

: Alarm reset available / ×: Alarm reset unavailable

Manual No.: ME0260-9A

CON

ERR

Status LED

Upstream Side

LK1 (link 1)LED

Downstream

Side

LK2 (link 2)LED

×

No. of Encoder Pulses

×

≤

2

31

* Refer to instruction manual of operation

for servo press type.

Top View of

Connector on

Controller side

L.ER

LINK

L.ER

LINK

Master Unit

Slave Devices

SCON CC-Link IE Type

Ethernet Straight Cable Category 5e or more

Double shielded cable braided with aluminum foil recommended

(Note) Terminal resistance is not required

There is no distinction

of IN/OUT on the

connector.

→

No →

→

No →

↓ Yes

No →

→

Check the emergency stop circuit.

→

No →

↓ Yes

↓ Yes

↓ Yes

→

Yes

Check of Packed Items

Are there all the delivered items?

Please contact the distributor.

Point Check Item

• Is frame ground (FG) connected?

• Has the noise countermeasure been taken?

Power Supply and Alarm Check

Connect a teaching tool such as PC, turn the mode changeover

switch to “MANU” side and turn the power on for each unit.

Select [Teaching Mode 1 Safety Speed Activated / PIO

Operation Invalid] in the teaching tool such as PC.

Check Item

Is the orange light [ALM] on

the LED status display off?

Connect the PC or teaching

pendant and check the

content of the alarm to have

the right treatment.

Safety Speed Setting

Set it in Parameter No. 35 if necessary. The safety speed is set to 100mm/s at the delivery.

Servo ON

Turn the servo on with the operation on the teaching

tool such as PC.

Check Item

Is the green light [SV] on

the LED status display on?

If an alarm is generated, connect

the PC or teaching pendant and

check the content of the alarm to

have the right treatment.

CAUTION

Please perform this process with the actuator away from the mechanical end or

interfering subjects as much as possible.

Put the actuator away if it interferes with surroundings. It may generate an alarm if the

actuator hit the mechanical end or interfering subjects when the servo is turned on.

The slider may get slightly dropped by self-weight if servo on and off is repeatedly

performed at the same position. Be careful not to pinch the hand or damage the work.

Safety Circuit Check

Does the emergency stop circuit (drive cutoff circuit) work properly and

turn the servo off?

Target Position Setting (This section is not necessary for □□ Direct Mode and MECHATROLINK-

III

.)

Set the target position in “Position” Box in each position table.

Perform a home-return operation first when Direct Teaching is to be performed. When moving the

actuator manually, set the Brake Release Switch to “BK RLS” side for the brake equipped type.

Put the switch back after the setting is complete.

CAUTION

To ensure safety, it is recommended that safety speed be enabled during initial movements.

If there is a vibration or abnormal

noise generated, check the actuator

if it is installed properly, the condition

for its use is below the rated

values, etc.

Test Run Adjustment

1) Check the operation with setting the safety speed invalid on the teaching tool such as PC software.

2)

Select “Monitor Mode 2 Safety Speed Invalid / PIO Available to Boot” in MANU

Operation Mode and remove the PC or teaching pendant from the controller.

3) Set the Mode Changeover Switch to “AUTO” side.

4) Conduct the Fieldbus setting on the host side.

Check Item

Turn on the power to the host side. Is the LED display on the front panel as shown below for each

Fieldbus?

CC-Link : STATUS 1 is off and STATUS 0 is turned on in green

DeviceNet and CompoNet : Both MS and NS are turned on in green

PROFIBUS, MECHATROLINK

I

and

II

: Both STATUS1 and STATUS0 are turned on in green.

Either of MECHATROLINK

III

- LK1 or LK2 is turned on in green

Now it is ready for operation. Proceed to the system operation adjustment.

↓ Yes

No

Installation and Wiring

Install and wire the actuator and the controller following the

instructions described in the Instruction Manual and this guide.

Initial Operation Check

Connect our controller to the actuator.

Connect a teaching tool such as PC, set the operation mode setting switch to “MANU” side and turn the power on.

Confirm the operation by performing a home-return operation and jog operation in full stroke range on the teaching tool.

↓

CAUTION

Be careful not to pinch the hand or damage the mechanical hand by the slider dropped with the

self-weight when turning the brake release switch to “BK RLS” side if it is mounted vertically.

↓ Yes

→ • Check the station number setting.

• Check the terminal resistor.

• Check the baud rate setting.

No