NF

*3

SK

*2

+24V

0V

L1

L2

L1C

L2C

NC

PE

BK

+

PWR

-

100V AC

or

200V AC

(Refer to Controller

Power Voltage Specifications)

Circuit

Breaker

Ground Fault

Circuit

Interrupter

CLF

*1

Class D grounding

(Formerly Class-

Ⅲ

grounding)

24V DC

Power

Supply

SCON

AC Power Supply

Input Connector

B. Motor Power Supply

A. Control Power Supply

Brake Power Supply

Input Connector

Brake

Release Box

Emergency

stop reset

switch

Emergency

stop switch

Cable for PC software

or dummy plug

Short-circuit in the

cable for PC software

System I/O connector

SIO connector

(Note 1)

(Note 1)

(Note 2)

(Note 3)

(Note 4)

Motor power

supply

Control power

supply

Temperature sensor contact

of external regenerative resistor

AC power supply

input connector

Emergency

stop circuit

exclusive use

24V

Stop Circuit

Contact output for the

external drive cutoff

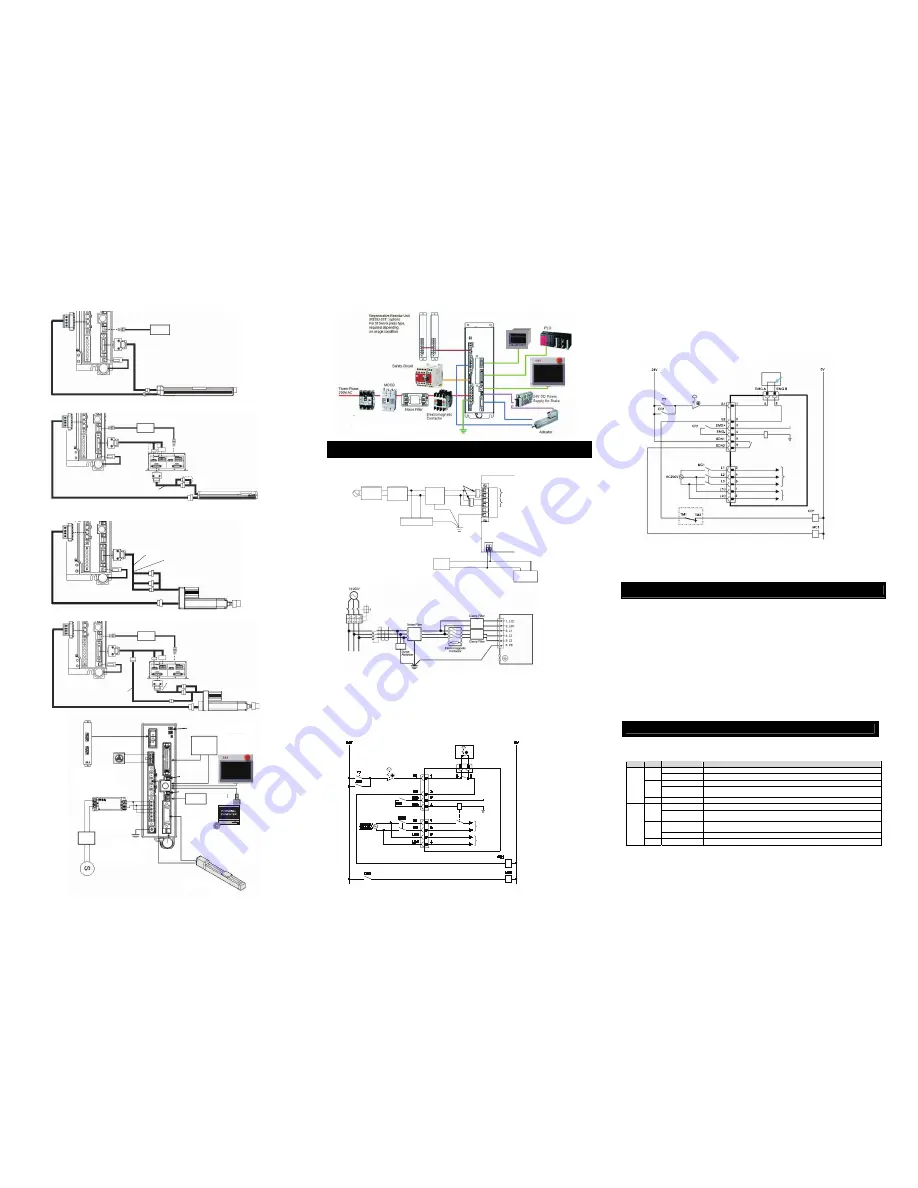

SCON-CGB

Circuit Breaker

Leakage Breaker

EMG Switch

Regenerative

Resistor Unit

Required depending

on usage condition

Noise Filter

Necessary to

noise prevention

Host

Controller

System

Circuit Breaker

Select and connect a circuit

breaker that can apply to

the capacity of controller

Actuator

PC Software

<RCM-101-USB>

Optional

PC

24V DC

NFB

Absolute

Battery

Brake for

Power Supply

Teaching Pendant

LED Display

Mode

Changeover

Switch

Brake Release Switch

Communication

Cable

Teaching Tool

Power Cutoff Breaker

As SCON-CGB for 3000 to 3300W does not have

the drive cutoff circuit, make sure to establish

cutoff externally.

Load Display

Device etc.

Communication

Cable

●

For Models Equipped with brake Except for RCS2-RA13R and NS Actuators

●

RSC2-RA13R Equipped with Brake, with no Loadcell, or NS Actuators with Brake

●

For RCS2-RA13R equipped with no brake and with loadcell for SCON-CA/CB/CGB or for when connecting

the servo press actuator to CB/CGB Servo Press Type

●

RCS2-RA13R Equipped with Brake and Loadcell in SCON-CA/CB/CGB

SCON-CAL/CGAL

SCON-CGB (For 3000 to 3300W Motor)

Power Supply and Emergency Stop Circuit

●

Wiring for Power Supply (to be prepared by customer)

SCON-C/CA/CAL/CGAL/CB/CGB (For ~750W Motor)

SCON-CGB (For 3000 to 3300W Motor)

Power consumption varies depending on the connected actuator, etc. Select the circuit breaker that suits to the specification.

[Refer to Basic Specifications]

A ground fault circuit interrupter needs to be selected carefully considering the purposes of prevention of fire and protection of

human. Use the “harmonic type” for the ground fault circuit interrupter. Also, check the leak current at the set points.

Refer to the instruction manual for the recommended models for the noise filter, clump filter and surge absorber.

●

Wiring for Emergency Stop Input

The following diagram shows an example of how the emergency stop switch for the teaching pendant may

be included in the emergency stop circuit you may construct.

SCON-C/CA/CAL/CGAL/CB/CGB (For ~750W Motor)

Note 1 The power rating of the motor power-off relay turning ON/OFF with contact CR1 is 24V DC and 10mA or less.

Note 2 Connect such as a connector to L1/L2 terminals when cutting off the motor power source externally.

Note 3 CGAL/CGB Types are not equipped with a relay to enable to automatically identify a teaching tool was inserted and

switch the wiring layout. (The system I/O connector does not get short-circuited between S1 and S2 terminals even if

a teaching tool is removed. Connect the enclosed dummy plug DP-5 to the SIO connector when it is necessary to

have short-circuit.) The controller on except for CGAL/CGB Types automatically identifies that a teaching tool was

inserted. (Short-circuit is made between S1 and S2 terminals inside the controller once connection is detected.)

Note 4 Since there is no motor power cutoff relay in CGAL/CGB Types, make sure to establish a cutoff relay externally.

SCON-CGB (For 3000 to 3300W Motor)

Note 1 The power rating of the motor power-off relay turning ON/OFF with contact CR1 is 24V DC and 10mA or less.

Note 2 Connect such as a connector to L1/L2/L3 terminals when cutting off the motor power source externally.

(This controler not equipped with the drive cutoff relay mounted inside the controller.)

Note 3 It is the contact output to control the drive source breaker connected externally. The rating is 30V DC and 20mA or less.

Note 4 Connect a temperature sensor when an external regenerative resistor unit is connected.

Operation Modes and Functions (other than MECHATROLINK-

Ⅲ

)

(Note) Refer to the Section for MECHATROLINK-

Ⅲ

for the operation modes and features of MECHATROLINK-

Ⅲ

.

SCON-C Type is available for the operation of Remote I/O Mode.

SCON-CA/CB/CGB Type is available for all the operation modes in the next table.

SCON-CAL/CGAL Type is available for the operations in the modes except for those in the shaded area in the next table.

The following operation modes are available to select for the operation.

(1) Remote I/O Mode

: This is the mode to perform operation by PIO (24V I/O) with Fieldbus.

(2) Position /

: This is the mode to perform operation by indicating the target position by inputting the value directly.

Simple Direct Mode The values of the position data already registered for the speed, acceleration/deceleration and

positioning band are to be used in this mode.

(3) Semi-Direct Mode

: This is the operation mode to indicate the speed, acceleration/deceleration and pressing

current, as well as the target position, by inputting the values directly.

(4) Full-Direct Mode

: This is the operation mode to indicate all related to the position control by inputting the values directly.

(5) Remote I/O Mode 2 : This is the mode that the function to read the current position and the current speed is added to Remote I/O.

(6) Position /

: This is the mode corresponding to the force control function instead of the teaching and zone

Simple Direct Mode 2 functions in (2).

(7) Semi-Direct Mode 2 : This is the mode that enables to read the loadcell data instead of reading the command current value in (3).

(8) Remote I/O Mode 3 : This is the mode that the function to read the current position and loadcell data is added to (1) functions.

(9) Semi-Direct Mode 3 : This is the mode that equips the vibration control function instead of the jog function in (3).

(10) Full Functional Mode

: It is a mode dedicated for the servo press type.

DeviceNet

●

Specification

Refer to the DeviceNet Instruction Manual [ME0256 : CA/CB Type, ME0124 : C Type]

●

LED Indicators for Monitoring

LED

Color Illumination Status

Explanation

Steady Light

In normal operation

GN

Blinking

A hardware error occurred. Condition sometimes recovers after the power reboot.

Steady Light

A hardware error occurred. Board must be replaced.

OR

Blinking

An error occurred in the user settings. It is just a simple error such like configuration

error. It can be recovered with a rebuild of the settings.

MS

−

Off

Power is not supplied during DeviceNet initializing.

Steady Light

Connection is established and the communication under normal condition

GN

Blinking

Online but network connection is not yet established. Communication is stopped.

(Network is in normal condition)

Steady Light

Node address duplication or bus-off state was detected. Communication is not

possible.

OR

Blinking

Communication error (Communication time-out is detected.)

NS

−

Off

Not online. DeviceNet Power is not supplied.

24V DC

Power Supply for Brake

Absolute Battery

(for Absolute Type)

Actuator

The following models are excluded:

•

RCS2-RA13R with brake or loadcell equipped

•

NS Actuators with brake equipped

24V DC

Power Supply for Brake

For LS (option)

Brake Box

CB-RCS2-PLA010

(enclosed to Brake Box)

For LS (option)

•

NS Actuators (with Brake

㧕

•

RCS2-RA13R (with Brake

㧕

Connect to back side

Absolute Battery

(for Absolute Type)

CB-LDC-LTL

CB-RCS2-PLLA

RCS2-RA13R

(with Loadcell and Brake)

CB-RCS2-PLA (enclosed to Brake Box)

24V DC

Brake Box

RCB-110-RA13-0

Connect to back side

Absolute Battery

(for Absolute Type)

Power Supply for Brake

Motor Power

Cutoff Relay

Motor power

supply

Control power

supply

(Note 3)

(Note 1)

(Note 1)

(Note 2)

(Note 4)

System I/O connector

SIO connector

EMG A

EMG B

Emergency

stop reset

switch

Emergency

stop switch

Emergency stop switch

for the teaching pendant

Emergency

stop circuit

exclusive use

24V

AC power supply

input connector

CB-RCS2-PLLA

RCS2-RA13R

(with Loadcel)

Absolute Battery

(for Absolute Type)

* For RCS3 servo press actuator:

It should be CB-RCS2-PLDA, and

cable should be 3 branched → 2 branched.